A kind of methanation catalyst and preparation method thereof

A methanation catalyst and catalyst technology, which can be used in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low conversion rate, achieve good carbon deposition resistance, and promote conversion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

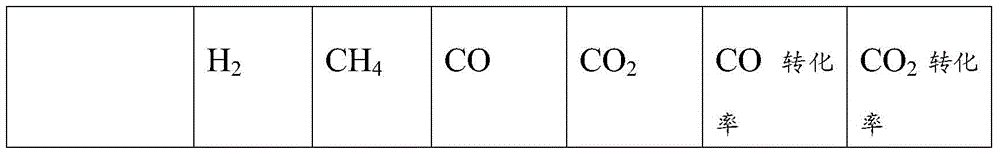

Examples

Embodiment 1

[0025] 1. Preparation of magnesium aluminum spinel

[0026] (a) MgO and Al 2 o 3 Mix the ingredients evenly at a molar ratio of 1:1, ball mill, dry and shape to obtain a spinel sample;

[0027] (b) pre-calcining the spinel sample at 250°C for 1 hour, then raising the temperature to 650°C for 1 hour, and cooling to room temperature to obtain a magnesium aluminum spinel precursor;

[0028] (c) Mixing and stirring the magnesium aluminum spinel precursor with nitric acid solution for 2 hours, filtering and drying, and calcining the dried sample at 700° C. for 2 hours to obtain the magnesium aluminum spinel.

[0029] 2. Preparation of catalyst

[0030] (1) Add 0.5 parts by weight of HMS mesoporous molecular sieves to the ethanol solution, then add 30 parts by weight of magnesium aluminum spinel, stir evenly, and obtain the catalyst carrier;

[0031] (2) drying the catalyst carrier obtained in step (1) at 100°C, and then calcining at 480°C for 2h to obtain a carrier precursor; ...

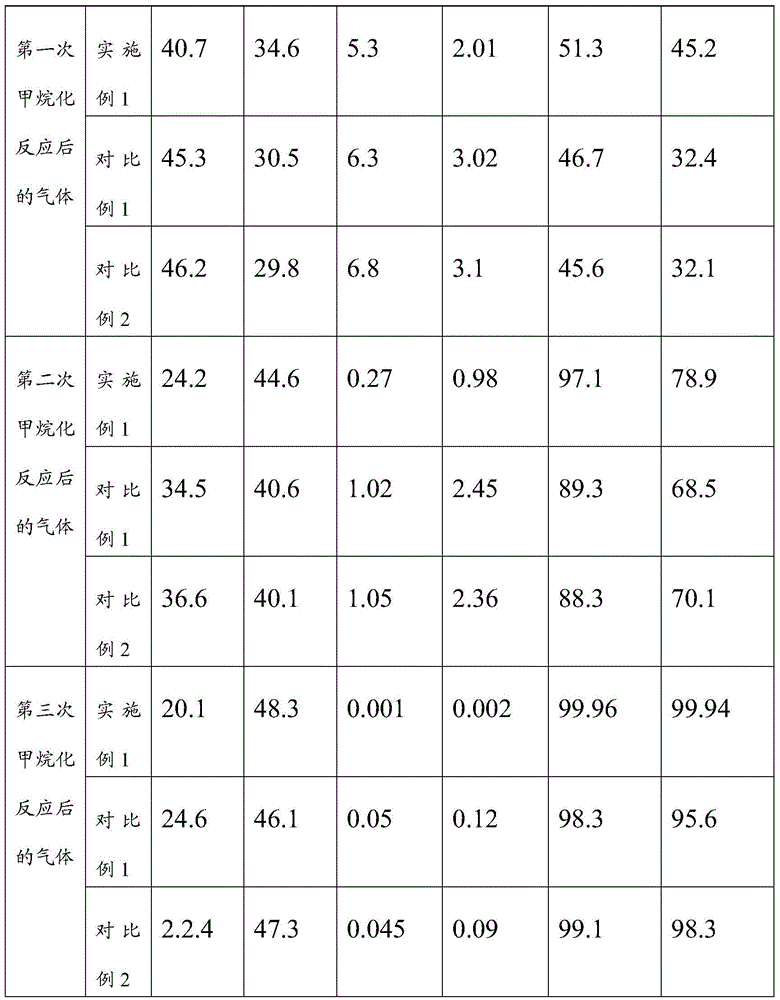

Embodiment 2

[0035] 1. Preparation of magnesium aluminum spinel

[0036] (a) MgO and Al 2 o 3 Mix the ingredients evenly at a molar ratio of 10:1, ball mill, dry and shape to obtain a spinel sample;

[0037] (b) pre-calcining the spinel sample at 120°C for 1 hour, then raising the temperature to 300°C for 6 hours, and cooling to room temperature to obtain a magnesium aluminum spinel precursor;

[0038] (c) Mixing and stirring the magnesium aluminum spinel precursor with nitric acid solution for 3 hours, filtering and drying, and calcining the dried sample at 700° C. for 2 hours to obtain the magnesium aluminum spinel.

[0039] 2. Preparation of catalyst

[0040] (1) Add 10 parts by weight of MCM-41 mesoporous molecular sieve into the ethanol solution, then add 20 parts by weight of magnesium aluminum spinel, stir evenly, and obtain the catalyst carrier;

[0041] (2) drying the catalyst carrier obtained in step (1) at 100° C., and then calcining at 450° C. for 2 hours to obtain a carrie...

Embodiment 3

[0045] 1. Preparation of magnesium aluminum spinel

[0046] (a) MgO and Al 2 o 3 Mix the ingredients evenly at a molar ratio of 8:1, ball mill, dry and shape to obtain a spinel sample;

[0047] (b) pre-calcining the spinel sample at 200°C for 1 hour, then raising the temperature to 400°C for 8 hours, and cooling to room temperature to obtain a magnesium aluminum spinel precursor;

[0048] (c) Mixing and stirring the magnesium aluminum spinel precursor with nitric acid solution for 2 hours, filtering and drying, and calcining the dried sample at 700° C. for 2 hours to obtain the magnesium aluminum spinel.

[0049] 2. Preparation of mesoporous molecular sieves

[0050] S1, add P123 to the aqueous hydrochloric acid solution and stir evenly, then add n-BuOH under stirring, continue stirring for 1 hour, then drop TEOS dropwise at 20°C to form a mixed system, the moles of each material in the mixed system The ratio is, TEOS:P123:HCl:H 2 O:BuOH=0.1:0.01:0.1:50:0.5;

[0051] S2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com