Preparation of crust oligosaccharide and use

A chitooligosaccharide and chitosan technology, which is applied in the field of preparation of chitooligosaccharides, can solve the problems of imperfect process, low product yield, increased production cost, etc., and achieve the improvement of chitin industry level and technical content High, promote the effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

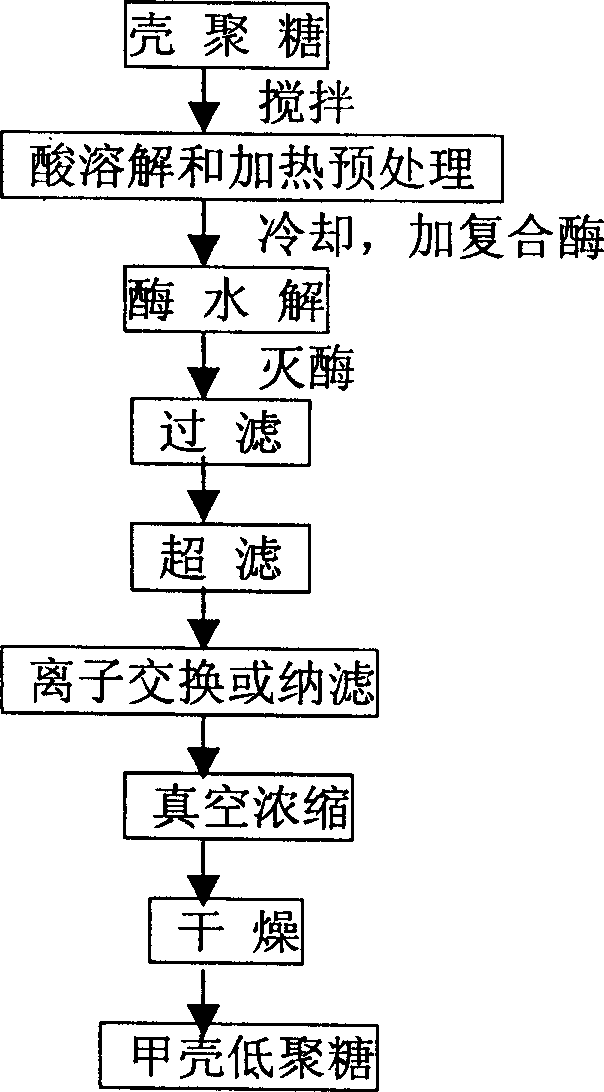

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 30kg of chitosan raw material in 500L of 3% acetic acid and 2% hydrochloric acid solution, heat to 60-90°C, and keep stirring until the chitosan dissolves. Adjust the pH of the chitosan solution to 3.5, and dissolve 0.3 kg of pectinase, pepsin, and lipase into the chitosan solution with a small amount of water for the compound enzyme composition, stir and react at 40°C for 5 hours, and the enzymatic hydrolysis reaction is completed. Inactivate the enzyme, filter, and the filtrate is separated by ultrafiltration, and the membrane molecule cut-off value is 5000. The ultrafiltrate is ion-exchanged with an ion-exchange column and strongly basic anion-exchange resin type 717 at room temperature, so that the pH value of the effluent reaches 5.5-6.5. The ion exchange effluent is vacuum concentrated and dried to obtain chitooligosaccharide powder.

Embodiment 2

[0039] Chitosan raw material 50kg, during acid dissolution and heating pretreatment, first use 3% acetic acid solution to dissolve chitosan, add 4% hydrochloric acid solution at the same time, and heat up to 90 ° C to reduce the viscosity of chitosan solution, the other conditions With embodiment 1.

Embodiment 3

[0041] Composite enzyme is composed of cellulase, papain, lipase, and all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com