Controlling method of rough rolling breakdown bar camber

A control method, camber technology, applied in rolling mill control devices, metal rolling, contour control, etc., can solve the problem that it is difficult to accurately find out the quantitative relationship between roll gap difference and camber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

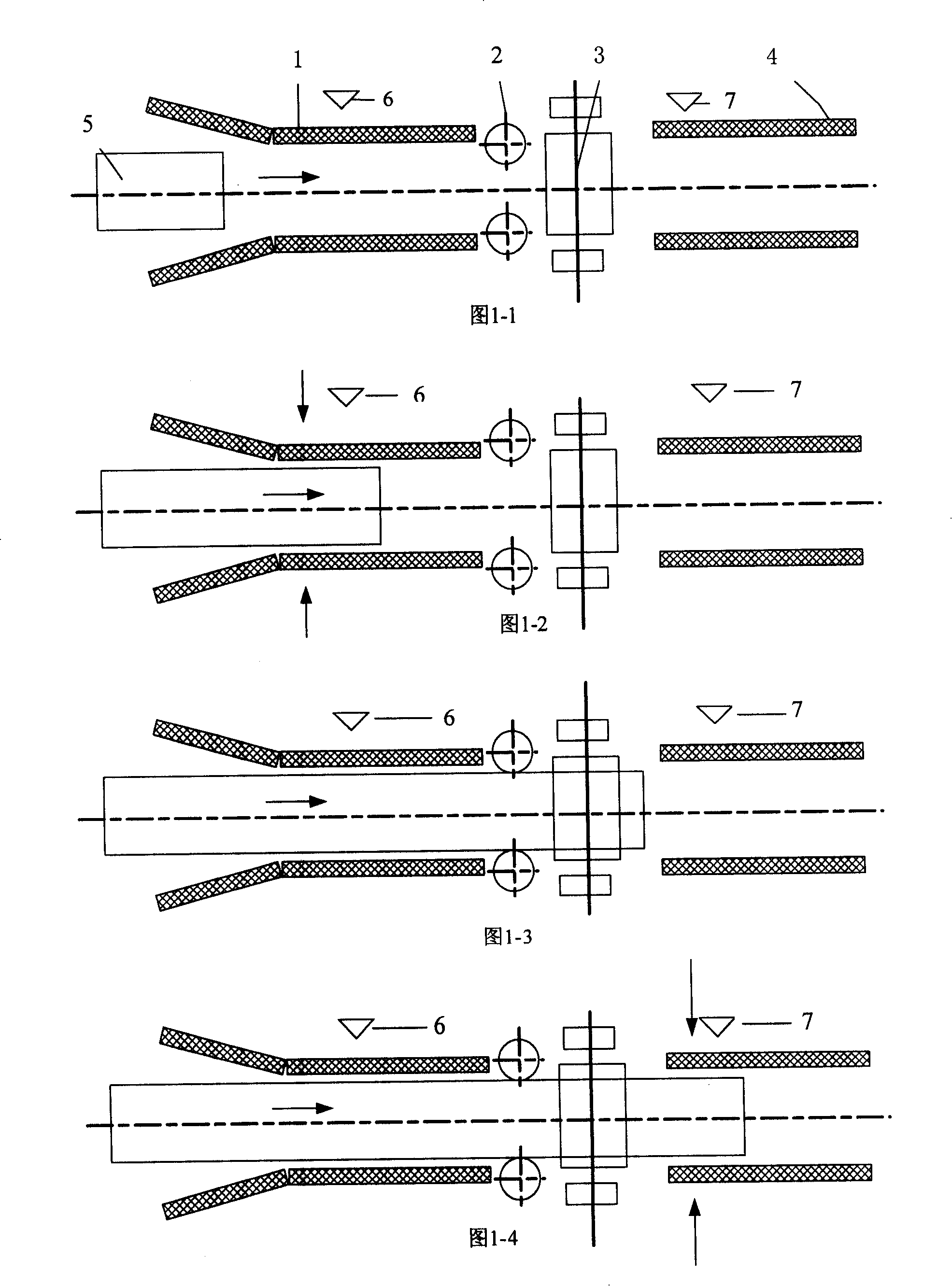

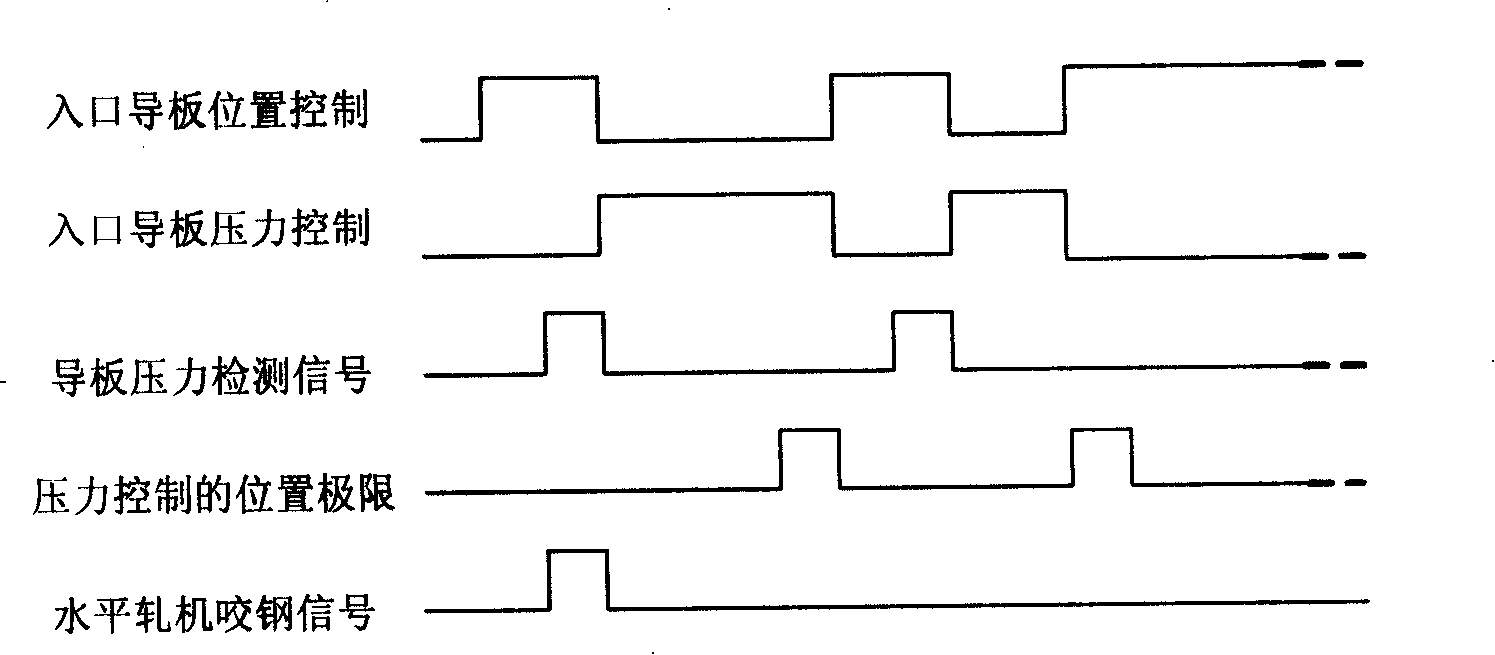

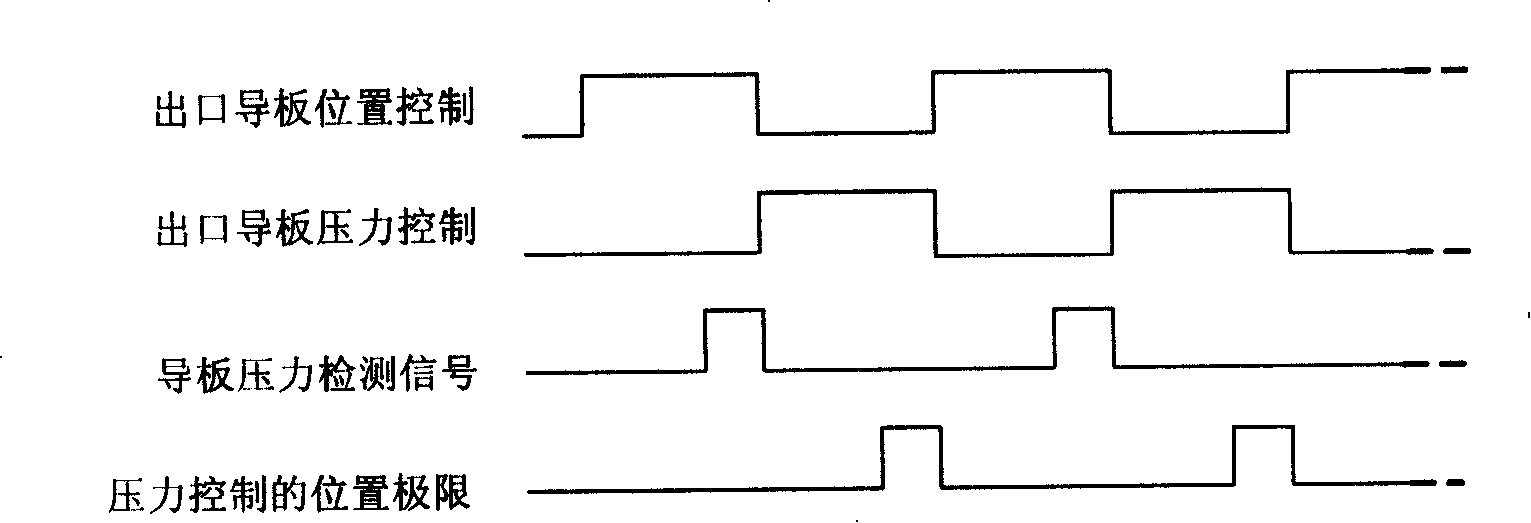

[0020] A method for controlling the sickle curve of the rough rolling intermediate slab, which is to jointly control the position and pressure of the side guide plate. In the multi-pass rolling of the forward and reverse passes of the rough rolling mill, the opening degree of the side guide plate can be reduced. The added value makes the side guide plate constrain the bending deformation of the intermediate billet at the entrance and exit of the roughing mill in the horizontal direction, so as to reduce the camber of the intermediate billet and prevent the side guide plate from being in contact with the intermediate billet for a long time to cause serious wear.

[0021] The position control of the side guide plate (APC for short) refers to the short stroke control of the side guide plate, that is, when the intermediate blank 5 does not enter the side guide plate 1, the opening degree of the side guide plate 1 is in the waiting position, and the opening degree is equal to that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com