Starch-based biodegradable plastic and preparation method thereof

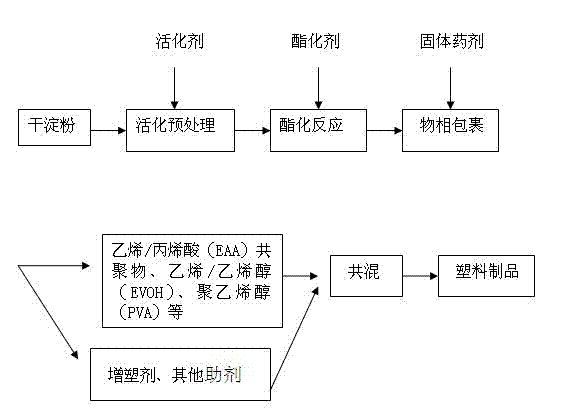

A biodegradable plastic and starch-based technology, applied in the field of plastic products, can solve the problems of insufficient reaction uniformity, increase the contact surface area and contact frequency between solid pharmaceuticals and starch molecules, etc., so as to improve the insufficient reaction uniformity and good economic Benefit and social benefit, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Weigh 100 parts by weight of cassava dry starch, add 0.3 parts by weight of activator solid sodium hydroxide (ground into powder), and perform activation treatment at 95-100° C. for 30 minutes. Then add 1 part of esterification agent sodium trimetaphosphate, and carry out esterification reaction at 120-125° C. for 1 hour. Add 2.5 parts by weight of solid medicament coupling agent titanate to the product after esterification reaction, and carry out phase encapsulation reaction under a fully stirred state, the reaction temperature is 125-130° C., and the reaction time is 50 minutes. Finally, it is blended with ethylene / acrylic acid (EAA) copolymer, ethylene / vinyl alcohol (EVOH) copolymer, polyvinyl alcohol (PVA), plasticizer, and other additives to make plastic products.

Embodiment 2

[0035] Weigh 100 parts by weight of cassava dry starch, add 0.8 parts by weight of activator solid sodium hydroxide (ground into powder), and perform activation treatment at 95-100° C. for 30 minutes. Then, 1.2 parts by weight of esterification agent sodium trimetaphosphate was added, and the esterification reaction was carried out at 120-125° C. for 1 hour. Add 3.5 parts by weight of solid drug coupling agent aluminate to the product that has undergone the esterification reaction, and carry out phase encapsulation reaction under a fully stirred state. The reaction temperature is 125-130° C., and the reaction time is 40 minutes. Finally, it is blended with ethylene / acrylic acid (EAA) copolymer, ethylene / vinyl alcohol (EVOH) copolymer, polyvinyl alcohol (PVA), plasticizer, and other additives to make plastic products.

Embodiment 3

[0037] Weigh 100 parts by weight of tapioca starch, add 1.0 parts by weight of activator solid sodium hydroxide (ground into powder) in the early stage of the reaction, and perform activation pretreatment at 95-100°C for 30 minutes; then add 1 part by weight of esterification agent Sodium trimetaphosphate, carry out esterification reaction at 120-125°C for 1 hour; then add 3.0 parts by weight of solid drug coupling agent borate, and carry out phase wrapping reaction under fully stirred state, the reaction temperature is 125- 130°C, reaction time 40-50 minutes; obtain modified starch, and ethylene / acrylic acid (EAA) copolymer, ethylene / vinyl alcohol (EVOH) copolymer, polyvinyl alcohol (PVA), plasticizer, other additives, etc. Blending to make biodegradable plastic products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com