Method for preparing ternary precursor material by recycling copper sulfide slag

A copper sulfide and precursor technology, applied in the field of nickel-cobalt hydrometallurgy, can solve the problems of low product added value, long processing flow, high energy consumption, etc., and achieve the effects of low product added value, long processing flow and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

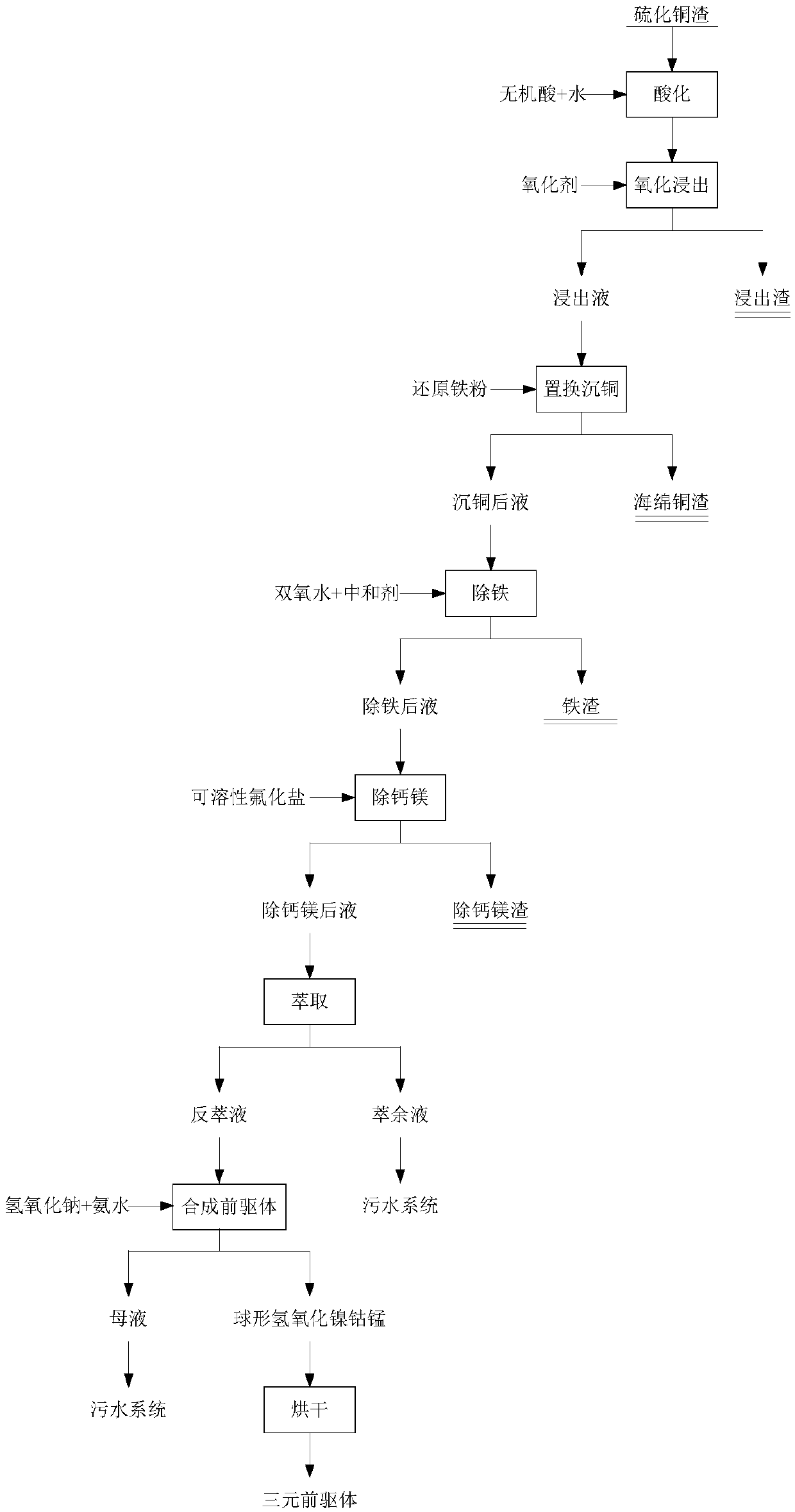

Method used

Image

Examples

Embodiment 1

[0048] (1) Acidification: Add 300kg copper sulfide slag and 0.6m 3 The tap water is made into slurry, and the pH value of the slurry is adjusted to pH 1.0 with 55kg of sulfuric acid. Among them, the valuable metal components and their mass percentages in the copper sulfide slag are: Cu: 5.21%, Ca: 0.015%, Cd: 0.11%, Mg: 0.012%, Fe: 0.21%, Co: 3.31%, Ni: 11.63 %, Mn: 1.15%.

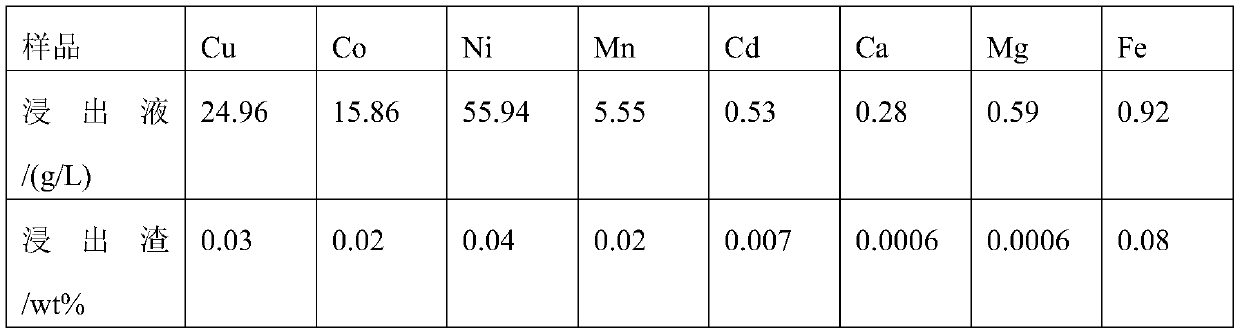

[0049] (2) Oxidative leaching: Add 42kg of sodium chlorate to the prepared slurry, keep the system temperature at 50°C, stir and react for 1.5h, then press filter to obtain 0.62m 3 Leaching solution and 45kg leaching residue. The analysis results of the leachate and leach residue are shown in Table 1.

[0050]Table 1 Analysis results of main components in leaching residue and leaching solution

[0051]

[0052] (3) Substitution of copper precipitation: Add 15kg of reduced iron powder to the leaching solution in step (2), control the reaction temperature at 30°C, react for 0.5h and filter to obtain 0...

Embodiment 2

[0067] (1) Acidification: Add 500kg copper sulfide slag and 2.5m 3 The tap water is made into slurry, and the pH of the slurry is adjusted to pH 1.0 with 82kg of sulfuric acid. Among them, the valuable metal components and their mass percentages in copper sulfide slag are: Cu: 2.63%, Ca: 0.025%, Cd: 0.01%, Mg: 0.015%, Fe: 0.18%, Co: 10.56%, Ni: 2.20 %, Mn: 1.20%.

[0068] (2) Oxidative leaching: Add 57kg of sodium chlorate and 24kg of hydrogen peroxide to the prepared slurry, keep the system temperature at 95°C, stir for 5 hours and press filter to obtain 2.6m 3 Leaching liquid and 102kg leach residue. The analysis results of leachate and leach residue are shown in Table 6.

[0069] Table 6 Analysis results of main components in leach residue and leach solution

[0070]

[0071] (3) Substitution of copper precipitation: add 20.5kg of reduced iron powder to the leaching solution, control the reaction temperature at 80°C, stir for 0.5h and filter to obtain 2.59m 3 After ...

Embodiment 3

[0086] (1) Acidification: Add 500kg copper sulfide slag and 2.5m 3 The tap water is made into a slurry, and the pH of the slurry is adjusted to pH 2.0 with 75kg of sulfuric acid. Among them, the main components and their mass percentages in the copper sulfide slag are: Cu: 4.86%, Ca: 0.31%, Cd: 0.21%, Mg: 0.055%, Fe: 0.93%, Co: 1.52%, Ni: 1.31%, Mn: 12.33%.

[0087] (2) Oxidative leaching: Add 93kg of sodium chlorate to the prepared slurry, keep the system temperature at 70°C, stir and react for 3.5h, then press filter to obtain 2.55m 3 Leaching liquid and 100kg leach residue. The analysis results of leachate and leach residue are shown in Table 11.

[0088] Table 11 Analysis results of main components in leach residue and leach solution

[0089] sample

Cu

co

Ni

mn

Cd

Ca

Mg

Fe

Leaching solution (g / L)

9.50

2.97

2.56

24.06

0.41

0.48

0.11

1.18

Leach residue / wt%

0.02

0.05

0.02

0.02

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com