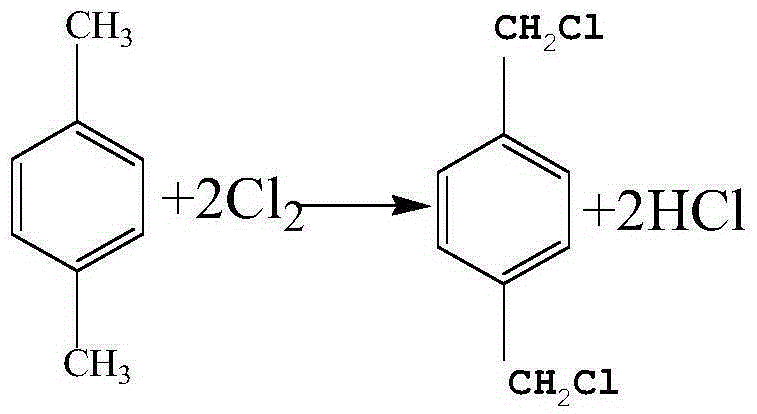

Continuous production process of p-xylylene dichloride and device

A technology for the production of p-dichlorobenzyl, which is applied in the field of organic chemical synthesis, can solve the problems of low product yield, high production cost, and discontinuous production, and achieve simple device structure, low cost, and good physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

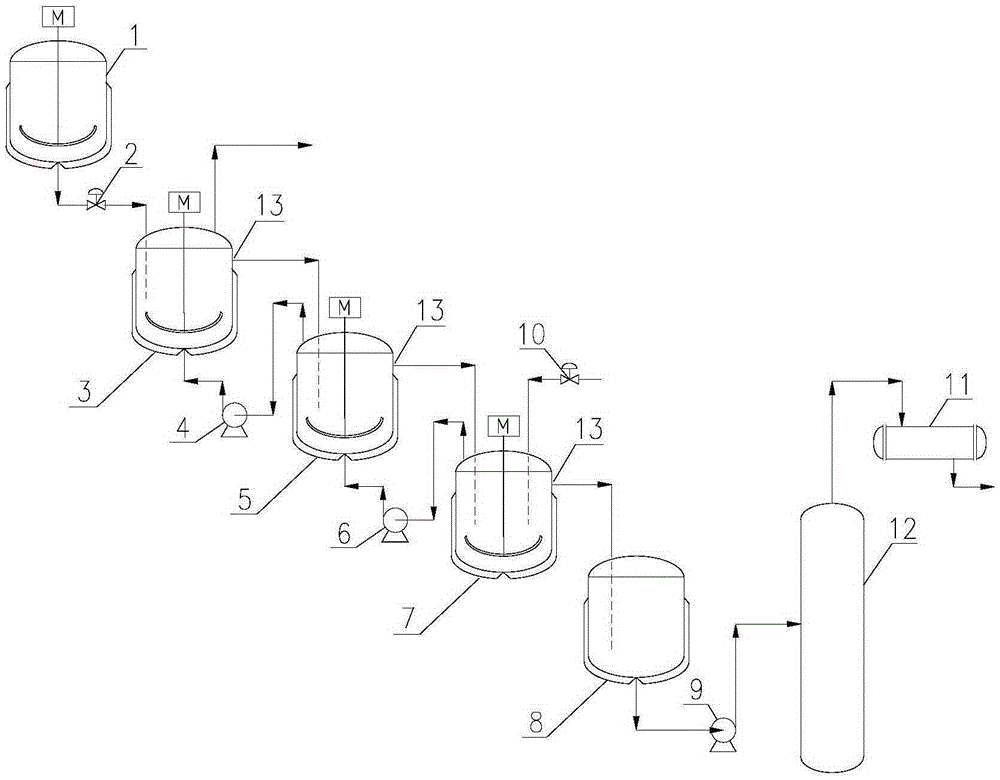

[0027] The device used in this example is figure 1 As shown, feed tank 1 is connected with three-stage chlorination still 3, secondary chlorination still 5, first-level chlorination still 7, separation tank 8 and rectifying tower 12 successively, and first-level chlorination still 7 and secondary chlorine Between the chlorination stills 5, between the secondary chlorination stills 5 and the third-level chlorination stills 3, all are connected in parallel; the feed tank 1 is connected with the third-level chlorination stills 3 through the feed valve 2, and the third-level chlorination stills 3 The bottom is connected to the secondary chlorination kettle 5 through the secondary reflux pump 4, the bottom of the secondary chlorination kettle 5 is connected to the primary chlorination kettle 7 through the primary reflux pump 6, and the bottom of the separation tank 8 is connected to the rectifying tank 8 through the feed pump 9. The towers 12 are connected, the top of the primary c...

Embodiment 2

[0034] The device used in this embodiment is as in Example 1, except that between the feed tank 1 and the three-stage chlorination kettle 3, between the three-stage chlorination kettle 3 and the secondary chlorination kettle 5, the secondary chlorination The potential difference between the kettle 5 and the primary chlorination kettle 7, and between the primary chlorination kettle 7 and the separation tank 8 is 2m.

[0035] The specific operation is as follows:

[0036] (1) p-Xylene and 1-dodecyl-3-methylimidazolium chloride salt are joined in the feed tank 1, wherein 1-dodecyl-3-methylimidazolium chloride salt is 5% of the p-xylene quality ‰, and then the feed valve 2 at the bottom of the feed tank 1 flows into the three-stage chlorination kettle 3, the second-stage chlorination kettle 5 and the first-stage chlorination kettle 7 in order. Port 13 to feed, then open the chlorine feed valve 10 on the top of the primary chlorination kettle 7, the material in the primary chlorin...

Embodiment 3

[0041] The device used in this embodiment is as in Example 1, except that between the feed tank 1 and the three-stage chlorination kettle 3, between the three-stage chlorination kettle 3 and the secondary chlorination kettle 5, the secondary chlorination The potential difference between the kettle 5 and the primary chlorination kettle 7, and between the primary chlorination kettle 7 and the separation tank 8 is 3m.

[0042] The specific operation is as follows:

[0043] (1) P-xylene and 1-butyl-2,3-methylimidazolium chloride are added to feed tank 1, wherein 1-butyl-2,3-methylimidazolium chloride is the quality of p-xylene 1‰, and then the feed valve 2 at the bottom of the feed tank 1 flows into the uniform material into the three-stage chlorination kettle 3, the secondary chlorination kettle 5 and the first-level chlorination kettle 7 respectively, and the reaction kettles at all levels Feed through the overflow port 13, then open the chlorine feed valve 10 on the top of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com