Secondary refrigerant and preparation method thereof, cooling structure, semiconductor laser bar and heat sink system

A cooling structure and semiconductor technology, applied in semiconductor lasers, lasers, laser parts, etc., can solve the problems of ice particles blocking heat sink microchannels, electrostatic ignition, etc., to improve electro-optical efficiency, prevent accumulation, and wide liquid temperature range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In an embodiment of another embodiment of the present invention, there is provided a method for preparing a refrigerant for a semiconductor laser bar operating at a low temperature according to the above solution, which may include: adding alcohol to the fluoride.

[0042] In an optional embodiment, the volume ratio of the fluoride to the alcohol is 100:1-2:1.

[0043] In an optional embodiment, it may further include: stirring, stirring the fluoride and the alcohols evenly.

[0044]In an optional embodiment, the fluoride is one or more of pentafluoropropane, hexafluoropropane, heptafluoropropane and Freon.

[0045] In an optional embodiment, the alcohols are one or more of methanol, ethanol, and ethylene glycol.

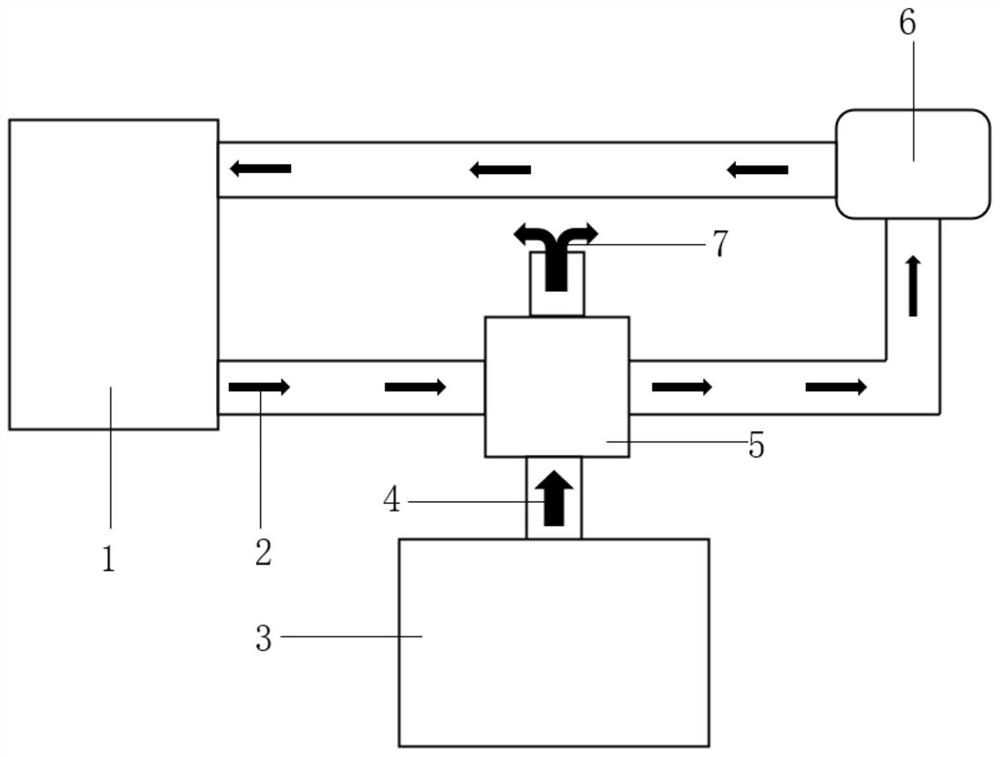

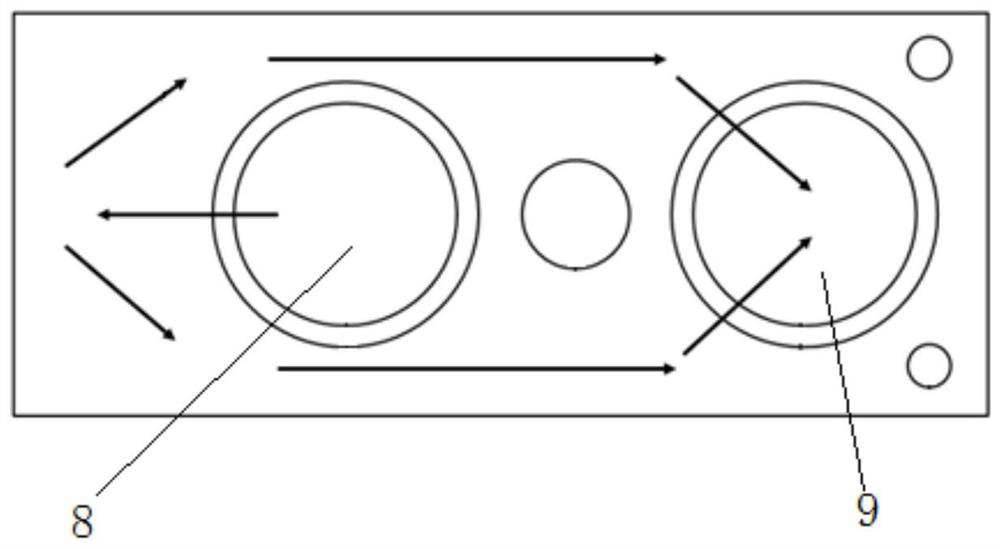

[0046] figure 1 It is a structural schematic diagram of a microchannel heat sink cooling structure according to an embodiment of the present invention.

[0047] Such as figure 1 As shown, in an embodiment of another embodiment of the present invention, a ...

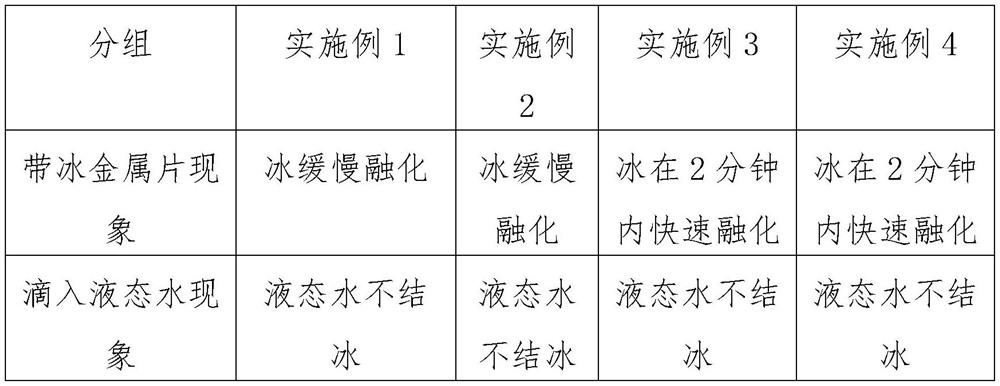

Embodiment 1

[0059] Add 100ml of pentafluoropropane and 10ml of dehydrated ethanol into the beaker, stir well with a glass rod, and measure the temperature of the mixed solution to be -25°C.

Embodiment 2

[0061] Add 100ml of pentafluoropropane and 20ml of dehydrated ethanol into the beaker, stir well with a glass rod, and measure the temperature of the mixed solution to be -25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com