Wet spinning method for polyacryl-nitrile fibre

A polyacrylonitrile fiber, wet spinning technology, applied in the direction of wet spinning, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the problem of high corrosion resistance requirements of production equipment and poor production and operation environment , strong corrosiveness of sodium thiocyanate and other issues, to achieve the effects of environmental protection, control, and strong solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The polyacrylonitrile resin is uniformly mixed with the ionic liquid to form a slurry, and the content of the polyacrylonitrile resin in the slurry is 12 wt%. Swell at a temperature of 18°C for 45 minutes, then heat up to 95°C and dissolve for 2.5 hours to form a uniform solution to make a spinning dope. The spinning stock solution is spun after filtering and defoaming, and the temperature of the stock solution is 115°C. The coagulation bath is an aqueous solution of ionic liquid, wherein the content of the ionic liquid is 24wt%, and the temperature of the coagulation bath is 45°C.

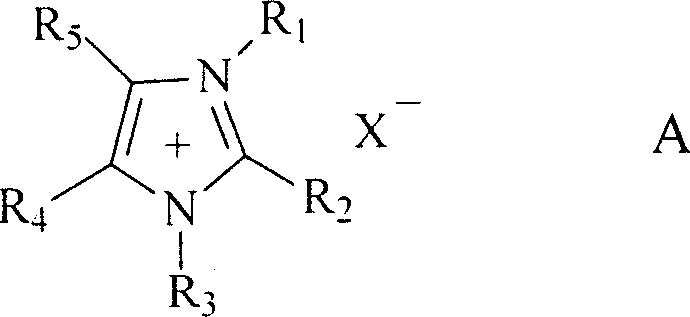

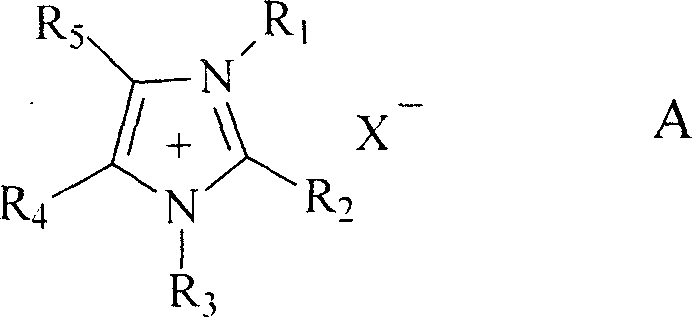

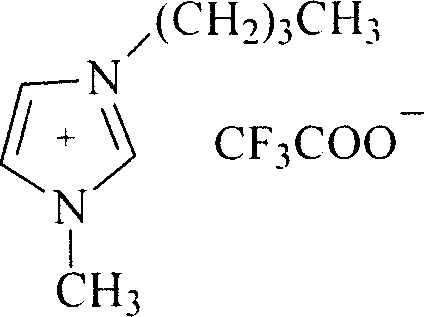

[0022] The ionic liquid adopted has the following structural formula:

[0023]

[0024] The spinning speed is 8m / min, and the coagulated and formed fibers are processed by subsequent processes such as washing, stretching, drying and setting, crimping and cutting to obtain polyacrylonitrile staple fibers with a specification of 2.2dtex×50mm. The measured breaking strength was 3.4 cN / d...

Embodiment 2

[0026] The polyacrylonitrile resin was uniformly mixed with the ionic liquid to form a slurry, and the content of the polyacrylonitrile resin in the slurry was 11 wt%. Swell at a temperature of 16°C for 65 minutes, then raise the temperature to 55°C and dissolve for 3.5 hours to form a uniform solution to make a spinning dope. The spinning stock solution is spun after filtering and defoaming, and the temperature of the stock solution is 110°C. The coagulation bath is an aqueous solution of ionic liquid, wherein the content of the ionic liquid is 25 wt%, and the temperature of the coagulation bath is 38°C.

[0027] The ionic liquid adopted has the following structural formula:

[0028]

[0029] The spinning speed is 7m / min, and the coagulated and formed fibers are processed by washing, stretching, drying and setting, crimping and cutting to obtain short polyacrylonitrile fibers with a specification of 3.6dtex×65mm. The measured breaking strength was 2.5 cN / dtex and the bre...

Embodiment 3

[0031] The polyacrylonitrile resin is uniformly mixed with the ionic liquid to form a slurry, and the content of the polyacrylonitrile resin in the slurry is 30 wt%. Swell at a temperature of 40°C for 35 minutes, then raise the temperature to 110°C and dissolve for 3 hours to form a uniform solution to make a spinning dope. The spinning stock solution is spun after filtering and defoaming, and the temperature of the stock solution is 120°C. The coagulation bath is an aqueous solution of ionic liquid, wherein the content of the ionic liquid is 35 wt%, and the temperature of the coagulation bath is 60°C.

[0032] The ionic liquid adopted has the following structural formula:

[0033]

[0034] The spinning speed is 8m / min, and the coagulated fibers are washed, stretched, dried and shaped, crimped and cut to obtain short polyacrylonitrile fibers with a specification of 3.2dtex×65mm. The measured breaking strength was 2.9 cN / dtex and the breaking elongation was 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com