Wet spinning method for polyacryl-nitrile fibre

A polyacrylonitrile fiber, wet spinning technology, applied in the direction of wet spinning, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the extremely high corrosion resistance requirements of production equipment, sodium thiocyanate strong Corrosiveness, production environment air pollution and other issues, to achieve the effect of environmental protection, strong solubility, wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The polyacrylonitrile resin is uniformly mixed with the ionic liquid to form a slurry, and the content of the polyacrylonitrile resin in the slurry is 23 wt%. Swell at a temperature of 40°C for 10 minutes, then heat up to 150°C and dissolve for 2 hours to form a uniform solution to make a spinning dope. The spinning stock solution is spun after filtering and defoaming, and the temperature of the stock solution is 150°C. The coagulation bath is an aqueous solution of ionic liquid, wherein the content of the ionic liquid is 20 wt%, and the temperature of the coagulation bath is 50°C.

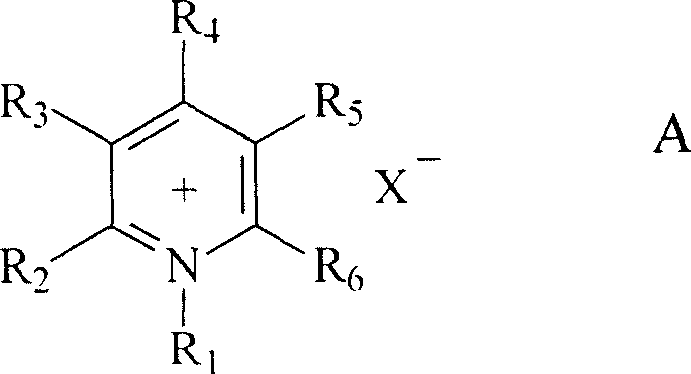

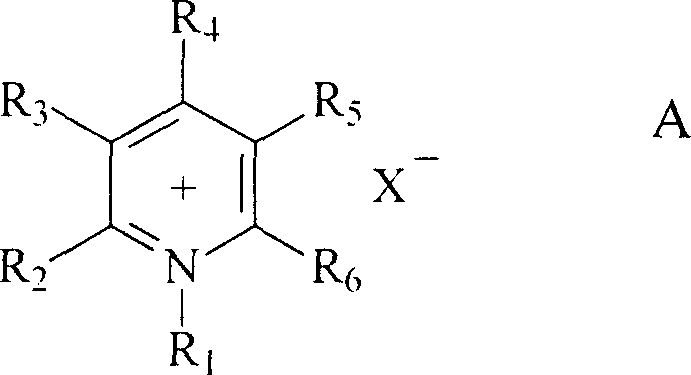

[0023] The ionic liquid adopted has the following structural formula:

[0024]

[0025] The spinning speed is 6m / min, and the coagulated and formed fibers are processed by subsequent processes such as washing, stretching, drying and setting, crimping and cutting to obtain short polyacrylonitrile fibers with a specification of 2.5dtex×65mm. The measured breaking strength was 3.5 cN / dtex...

Embodiment 2

[0027] The polyacrylonitrile resin and the ionic liquid are uniformly mixed to form a slurry, and the content of the polyacrylonitrile resin in the slurry is 10 wt%. Swell at a temperature of 18°C for 55 minutes, then raise the temperature to 60°C and dissolve for 4.5 hours to form a uniform solution to make a spinning dope. The spinning stock solution is spun after filtering and defoaming, and the temperature of the stock solution is 100°C. The coagulation bath is an aqueous solution of ionic liquid, wherein the content of the ionic liquid is 20 wt%, and the temperature of the coagulation bath is 35°C.

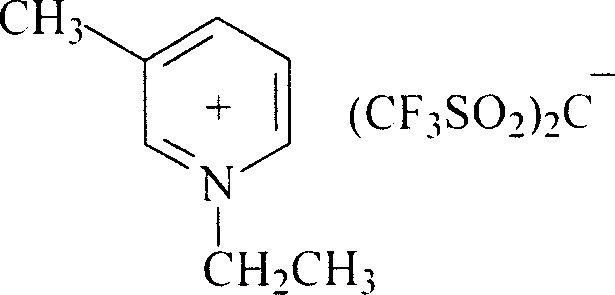

[0028] The ionic liquid adopted has the following structural formula:

[0029]

[0030] The spinning speed is 9m / min, and the coagulated and formed fibers are processed by subsequent processes such as washing, stretching, drying and setting, crimping and cutting to obtain polyacrylonitrile staple fibers with a specification of 3.8dtex×75mm. The measured breaking streng...

Embodiment 3

[0032] The polyacrylonitrile resin is uniformly mixed with the ionic liquid to form a slurry, and the content of the polyacrylonitrile resin in the slurry is 12 wt%. Swell at a temperature of 20°C for 40 minutes, then raise the temperature to 100°C and dissolve for 3.5 hours to form a uniform solution to make a spinning dope. The spinning stock solution is spun after filtering and defoaming, and the temperature of the stock solution is 110°C. The coagulation bath is an aqueous solution of ionic liquid, wherein the content of the ionic liquid is 27wt%, and the temperature of the coagulation bath is 40°C.

[0033] The ionic liquid adopted has the following structural formula:

[0034]

[0035] The spinning speed is 6m / min, and the coagulated and formed fibers are processed by subsequent processes such as washing, stretching, drying and setting, crimping and cutting to obtain polyacrylonitrile staple fibers with a specification of 3.3dtex×65mm. The measured breaking strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com