Rubber block isolating agent for breaking natural rubber, and preparation method thereof

A natural rubber and release agent technology, applied in the field of rubber additives, can solve problems such as endangering the health of operators, affecting the performance of compound rubber, polluting the working environment, etc., and achieve the effects of benefiting human health, improving isolation performance, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

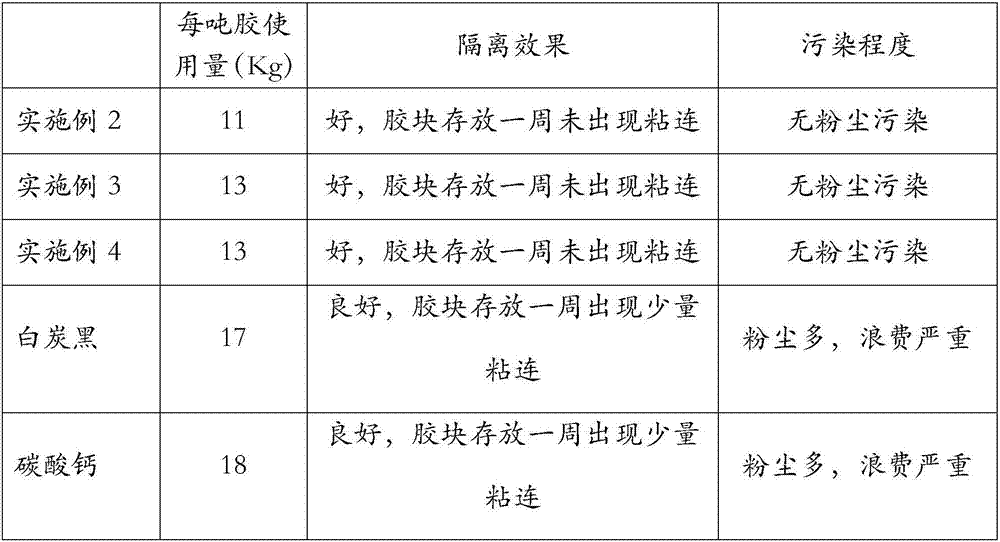

Examples

Embodiment 1

[0025] A rubber block release agent for natural rubber crushing, the rubber block release agent includes the following components in parts by weight:

[0026] 10-20 parts of fatty acid ester, 10-20 parts of fatty acid, 1-10 parts of organic filler, 60-75 parts of inorganic carrier;

[0027] The fatty acid ester is one or more of pentaerythritol tetrastearate, glyceryl stearate, and propylene glycol stearate;

[0028] The fatty acid is one or more of stearic acid, palmitic acid and lauric acid;

[0029] The organic filler is one or a combination of fatty acid calcium and fatty acid zinc;

[0030] The inorganic carrier is one or a combination of silicate fillers and calcium carbonate fillers;

[0031] The silicate filler is white carbon black or kaolin.

[0032] The preparation method of above-mentioned rubber block release agent comprises the steps:

[0033] S1. Add fatty acid ester, fatty acid and organic filler into the reaction kettle, heat and melt while stirring and ke...

Embodiment 2

[0037] A rubber block release agent for natural rubber crushing, the rubber block release agent includes the following components in parts by weight:

[0038] 10 parts of pentaerythritol tetrastearate, 15 parts of palmitic acid, 5 parts of calcium fatty acid, 30 parts of white carbon black, 40 parts of calcium carbonate.

[0039] The preparation method of above-mentioned rubber block release agent comprises the steps:

[0040] S1. Add 10 parts of pentaerythritol tetrastearate, 15 parts of palmitic acid, and 5 parts of fatty acid calcium into the reaction kettle, heat and melt while stirring and keep the temperature at 110° C. to obtain a molten mixture;

[0041] S2. Add 30 parts of white carbon black and 40 parts of calcium carbonate to the high-speed mixer, and spray the molten mixture obtained in step 1 into the mixer during high-speed stirring. After spraying, continue to stir at high speed for 15 minutes;

[0042] S3. Add the mixture prepared in step 2 to a granulator to ...

Embodiment 3

[0044] A rubber block release agent for natural rubber crushing, the rubber block release agent includes the following components in parts by weight:

[0045] 10 parts of glyceryl stearate, 10 parts of fatty acid, 5 parts of zinc unsaturated fatty acid, 25 parts of kaolin, 50 parts of calcium carbonate.

[0046] The preparation method of above-mentioned rubber block release agent comprises the steps:

[0047] S1. Add 10 parts of glyceryl stearate, 10 parts of fatty acid, and 5 parts of unsaturated fatty acid zinc into the reaction kettle, heat and melt while stirring and keep the temperature at 115° C. to obtain a molten mixture;

[0048] S2. Add 25 parts of kaolin and 50 parts of calcium carbonate to the high-speed mixer, and spray the molten mixture obtained in step 1 into the mixer during high-speed stirring. After the spraying is completed, continue to stir at high speed for 20 minutes;

[0049] S3. Add the mixture prepared in step 2 to a granulator to granulate and sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com