Enhanced polycarbonate extrusion grades

A technology described in polycarbonate, extrusion, applied in the field of thermoplastic compositions, capable of solving problems such as irregular processing or high release force, insufficient release behavior, deformation of ejected parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0151] High viscosity polycarbonate PC 103R formulated with three different release agents:

[0152] a) Pentaerythritol tetrastearate (PETS), 0.1 wt% to 0.4 wt%.

[0153] b) Glyceryl tristearate (GTS), 0.03% to 0.05% by weight.

[0154] c) Polyalphaolefin (PAO), 0.09 wt% to 0.4 wt%.

[0155] At various times, several batches were produced and sent to the extrusion line and then extruded in the form of multi-wall sheets. Each material was extruded for a minimum of 3 hours. Data on surface vibrations were collected and analyzed.

[0156] result:

[0157] Table 1 shows data for several batches of high viscosity polycarbonate used for multiwall sheet extrusion. Formulations containing a release agent other than tristearin showed surface vibrations, while those containing tristearin did not.

[0158] Table 1 : Results of visual inspection of surface vibrations on extruded profiles.

[0159]

Embodiment 2

[0161] High viscosity polycarbonate PC 103R was formulated with five different additive packages including one or more of the mold release agents, UV stabilizers, and heat stabilizers listed below.

[0162] Release agent:

[0163] a) Pentaerythritol tetrastearate, 0.2 wt% to 0.4 wt%.

[0164] b) Glyceryl tristearate, 0.03 wt% to 0.05 wt%.

[0165] UV stabilizer

[0166] a) UV 1-2-[2-Hydroxy-3,5-bis(1,1-dimethylbenzylphenyl)]-2H-benzotriazole, 0.2 wt% to 0.3 wt%.

[0167] b) UV2-2,2'-methylenebis(6-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetramethylbutyl)phenol), 0.1 wt% to 0.18 wt%.

[0168] c) UV3-Pentaerythritol tetrakis(diphenyl 2-cyano-3,3-acrylate), 0.1 wt% to 0.18 wt%.

[0169] Heat stabilizer: tris(2,4-di-tert-butylphenyl)phosphite (HS), 0.0075wt% to 0.03wt%.

[0170] The resulting material is sent to an extrusion line and then used as a capping layer on a multi-wall sheet (top and bottom). Each run lasted over 10 hours and the line settings were kept constant during t...

Embodiment 3

[0176] Table 3: Composition of test grades

[0177]

[0178] UV5411 is 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetramethylbutyl)-phenol (CYASORB TM 5411). Tin360 is a commercially available UV absorber.

[0179] The formulations of Table 3 were tested and the results are listed in Table 4 below. Fouling is the migration of material out of the polycarbonate body during processing and, as a result, deposits form on the surface of the extrusion profile and / or die orifice.

[0180] Buildup was determined by measuring the weight of the die after 8000 injections, cleaning the die, and washing deposits from the die surface. After cleaning, the die weight is measured again and the weight of the fouling or deposit is equal to the weight before cleaning minus the weight after cleaning. Fouling was determined using samples containing less than or equal to 200 ppm water.

[0181] Table 4: Composition data of standard PC103R with PETS+UV5411 versus reformulated PC103R with GTS and Tin36...

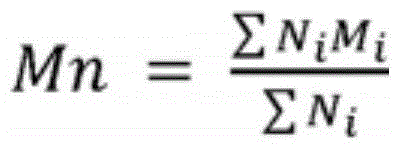

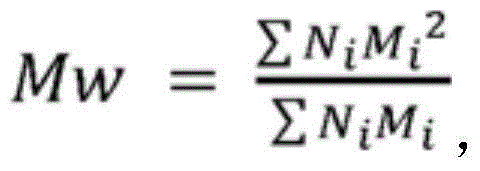

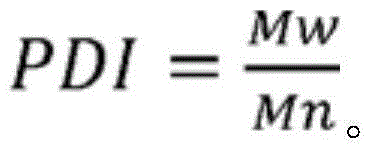

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com