Enhanced poly(butylene terephthalate-co-butylene adipate) degraded material

A technology of butanediol terephthalate and butanediol adipate, which is applied in the field of processing and modification of polymer materials, and can solve the problems of multiple components, insufficient strength of biological materials, and complex formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

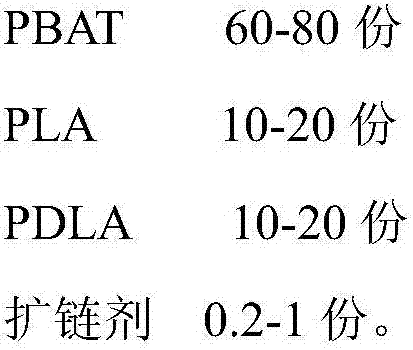

Method used

Image

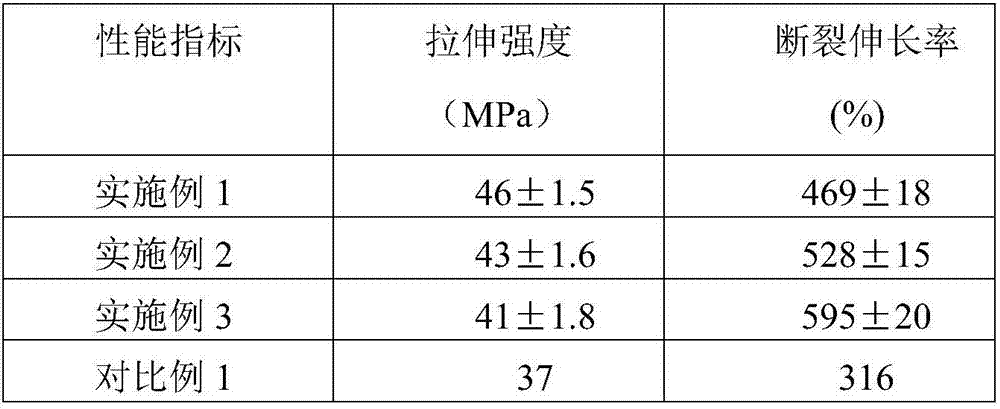

Examples

Embodiment 1

[0014] The pre-dried PBAT, PLA, and PDLA were weighed according to a certain proportion, and the total mass was 4kg. The content of PBAT is 60%, the content of PLA and PDLA is 20% each, and 40g of chain extender ethylene-methyl acrylate-glycidyl methacrylate is added, and mixed at high speed for 3 minutes using a high-speed mixer. The uniformly mixed material is fed into a twin-screw extruder, the temperature of each section of the screw is 150-195° C., the screw speed is 150 rpm, extruded and granulated, and a high-strength biodegradable material is prepared.

[0015] The dried pellets are added to the single-screw machine for extrusion blow molding. The temperature of each zone of the single-screw machine is: 160°C for the first zone, 175°C for the second zone, 185°C for the third zone, 185°C for the fourth zone, and 170°C for the head; 150rpm, aspect ratio L / D=24 / 1.

Embodiment 2

[0017] The pre-dried PBAT, PLA, and PDLA were weighed according to a certain proportion, and the total mass was 4kg. The content of PBAT is 70%, and the content of PLA and PDLA is 15%. In addition, 24g of chain extender ethylene-methyl acrylate-glycidyl methacrylate is added, and mixed at high speed for 3 minutes using a high-speed mixer. The homogeneously mixed material is fed into a twin-screw extruder, the temperature of each section of the screw is 160-195° C., the screw speed is 100 rpm, extruded and granulated, and a high-strength biodegradable material is prepared.

[0018] The dried pellets are added to the single-screw machine for extrusion blow molding. The temperature of each zone of the single-screw machine is: 155°C for the first zone, 175°C for the second zone, 195°C for the third zone, 175°C for the fourth zone, and 165°C for the head; 150rpm, aspect ratio L / D=24 / 1.

Embodiment 3

[0020] The pre-dried PBAT, PLA, and PDLA were weighed according to a certain proportion, and the total mass was 4kg. The content of PBAT is 80 parts, and the content of PLA and PDLA is 10 parts respectively. In addition, 8 g of chain extender ethylene-methyl acrylate-glycidyl methacrylate are added, and mixed at high speed for 3 minutes using a high-speed mixer. The uniformly mixed material is fed into a twin-screw extruder, the temperature of each section of the screw is 160-195° C., the screw speed is 150 rpm, extruded and granulated, and a high-strength biodegradable material is prepared.

[0021] The dried pellets are added to the single-screw machine for extrusion blow molding. The temperature of each zone of the single-screw machine is: 155°C for the first zone, 175°C for the second zone, 185°C for the third zone, 180°C for the fourth zone, and 175°C for the head; 150rpm, aspect ratio L / D=24 / 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com