Ultra-high molecular weight polyethylene tube and production technique thereof

An ultra-high molecular weight, polyethylene tube technology, applied in tubular articles, other household appliances, applications, etc., can solve the problems of high price of silicone and unfavorable large-scale production and use

Inactive Publication Date: 2012-09-19

HEBEI BEISU PIPE IND

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the price of organic silicon is relatively high, which is not conducive to large-scale production and use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-7

[0068] Table 2 embodiment 1-7 high-speed mixing process parameters

[0069]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidation induction time | aaaaa | aaaaa |

Login to View More

Abstract

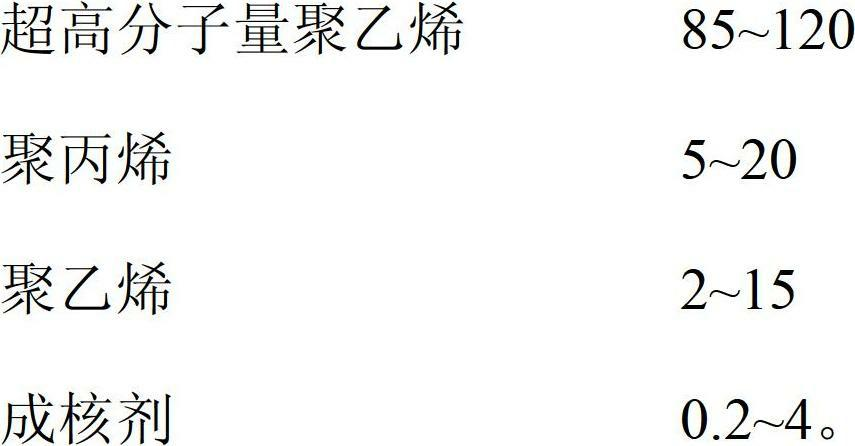

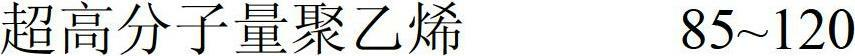

The invention relates to an ultra-high molecular weight polyethylene tube which is characterized by comprising the following components in parts by weight: 85-120 parts of ultra-high molecular weight polyethylene, 5-20 parts of polypropylene, 2-15 parts of polyethylene and 0.2-4 parts of nucleating agent. The tube can also comprise graphite and plastic assistants. The polypropylene and polyethylene are blended to modify the ultra-high molecular weight polyethylene, so the prepared ultra-high molecular weight polyethylene tube not only has the properties of the raw material, but also has the good characteristics of polyethylene and polypropylene; and thus, the ultra-high molecular weight polyethylene tube is easy to process, and has the advantages of favorable plastifying effect and high production efficiency.

Description

technical field [0001] The invention relates to a pipe material, in particular to an ultra-high molecular weight polyethylene pipe material and a production process thereof, and belongs to the technical field of research on the pipe material process formula. Background technique [0002] With the advancement of science and technology and the development of society, the application of polymer materials is becoming more and more extensive. With the guidance of national policies, plastic pipes are more and more widely used. UHMWPE pipes have excellent performance and are known as the "King of Plastics". Therefore, they are widely used in various fields. Ultra-high molecular weight polyethylene (UHMW-PE) has an average molecular weight of about 350,000 to 8 million. Because of its high molecular weight, it has excellent impact resistance, wear resistance, self-lubrication, and chemical corrosion resistance that other plastics cannot match. Moreover, ultra-high molecular weight ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/06C08L23/12C08K13/02C08K3/04B29C47/00B29B7/00B29K23/00B29L23/00

Inventor 佟照刚刘树生荆冰甄红英王希军胡永强张春然

Owner HEBEI BEISU PIPE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com