Bar inserting type heat insulation section material and preparation method thereof

A strip-threading and profile technology, which is applied in the field of thread-through heat insulation profile materials and its preparation, can solve the problems of high price, unsuitability for the development of building energy-saving doors and windows, and increase the cost of doors and windows, and achieve excellent mechanical properties and excellent processing appearance. Effects of decoration, processing adaptability, and use weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 100 parts of PVC with a polymerization degree of 1000, 60 parts of high heat-resistant resin, 5 parts of composite lead salt stabilizer, 0.4 part of lubricant, 10 parts of impact modifier, 0.2 part of antioxidant, 5 parts of active calcium carbonate, 1 part of acrylic ester processing aid, stirred to 110°C with a high-speed mixer, kept for 15 minutes, cooled to room temperature, plasticized at 170°C for 5 minutes with a double-roller plasticizer, and pressed into sheets to make 1mm and 4mm plates. Made tensile, impact, Vicat softening point test specimens, the test results are shown in Table 1.

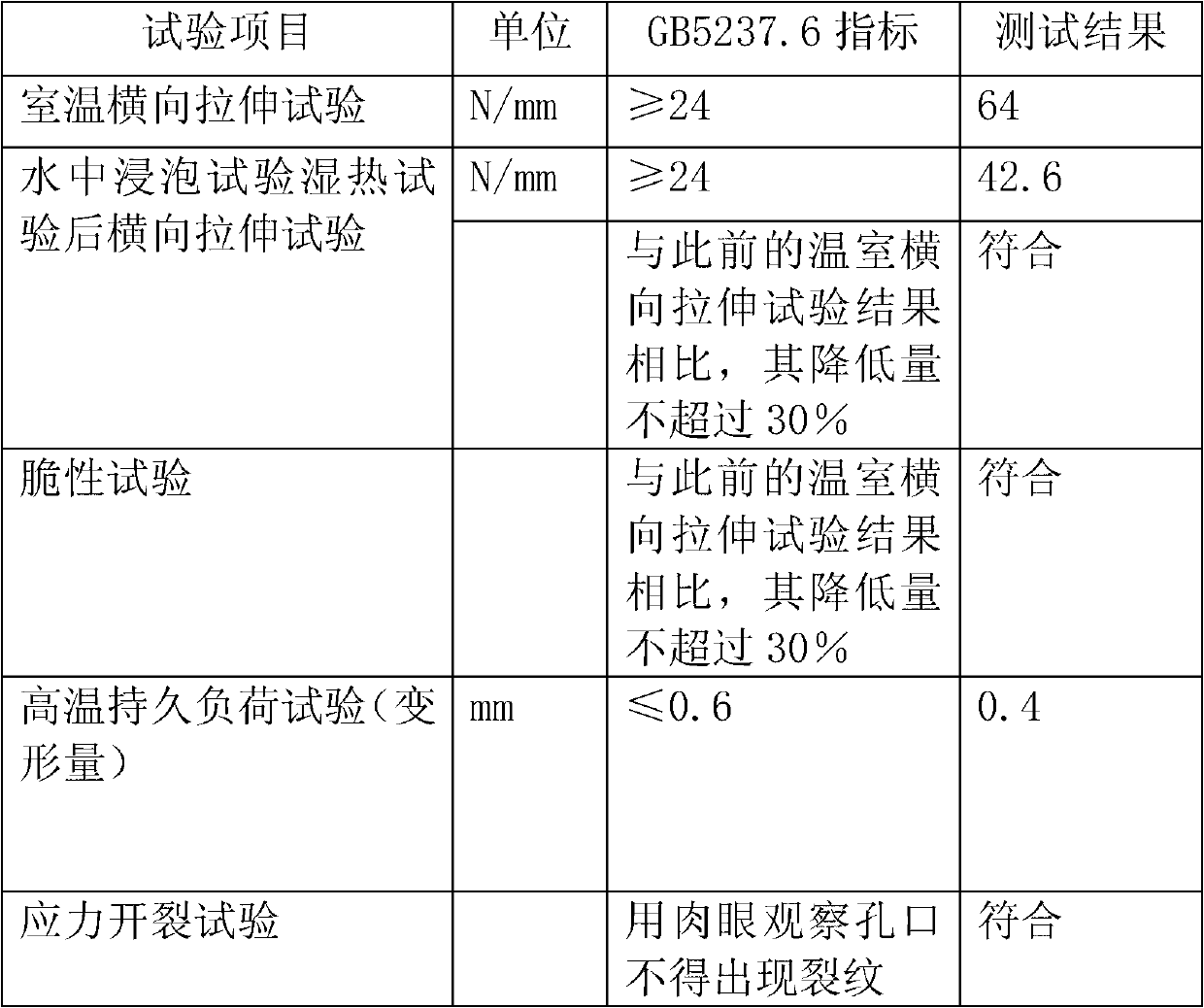

[0024] Table 1 Performance comparison of strip-type heat insulation profiles

[0025] performance parameters

Embodiment 2

[0027] 100 parts of PVC with a polymerization degree of 1000, 80 parts of high heat-resistant resin, 5 parts of rare earth stabilizer, 0.9 part of lubricant, 15 parts of impact modifier, 0.2 part of antioxidant, 10 parts of active talcum powder, 1 1 part of acrylate processing aid, stirred to 110°C with a high-speed mixer, kept for 20 minutes, cooled to room temperature, granulated with conical twin-screw, and then injected into impact, tensile, and Vicat softening point test samples with an injection machine The test results are shown in Table 2.

[0028] Table 2 Performance comparison of strip-type heat insulation profiles

[0029] performance parameter

Embodiment 3

[0031] 100 parts of PVC with a polymerization degree of 1000, 120 parts of high heat-resistant resin, 5 parts of organotin stabilizer, 1 part of lubricant, 15 parts of impact modifier, 0.5 part of antioxidant, 20 parts of active calcium carbonate, 3 parts 1 part of acrylate processing aid, stirred to 110°C with a high-speed mixer, kept for 15 minutes, cooled to room temperature, plasticized at 180°C for 5 minutes with a double-roller plasticizer, and pressed into sheets to make 1mm and 4mm plates. Test specimens for impact, tension, and Vicat softening point, and the test results are shown in Table 3.

[0032] Table 3 Performance comparison of strip-type heat insulation profiles

[0033] performance parameters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com