PPO/PA66 (poly phenylene oxide/polyamide 66) alloy material as well as preparation method and application thereof

A technology of alloy materials and mixtures, applied in the field of plastics, can solve the problems of weak strength and antistatic performance, and achieve the effects of high production efficiency, low cost and improved antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] see figure 1 , figure 1 Show the flow chart of the preparation method of the PPO / PA66 alloy material of the embodiment of the present invention, including the following steps:

[0029] Step S01, mixing

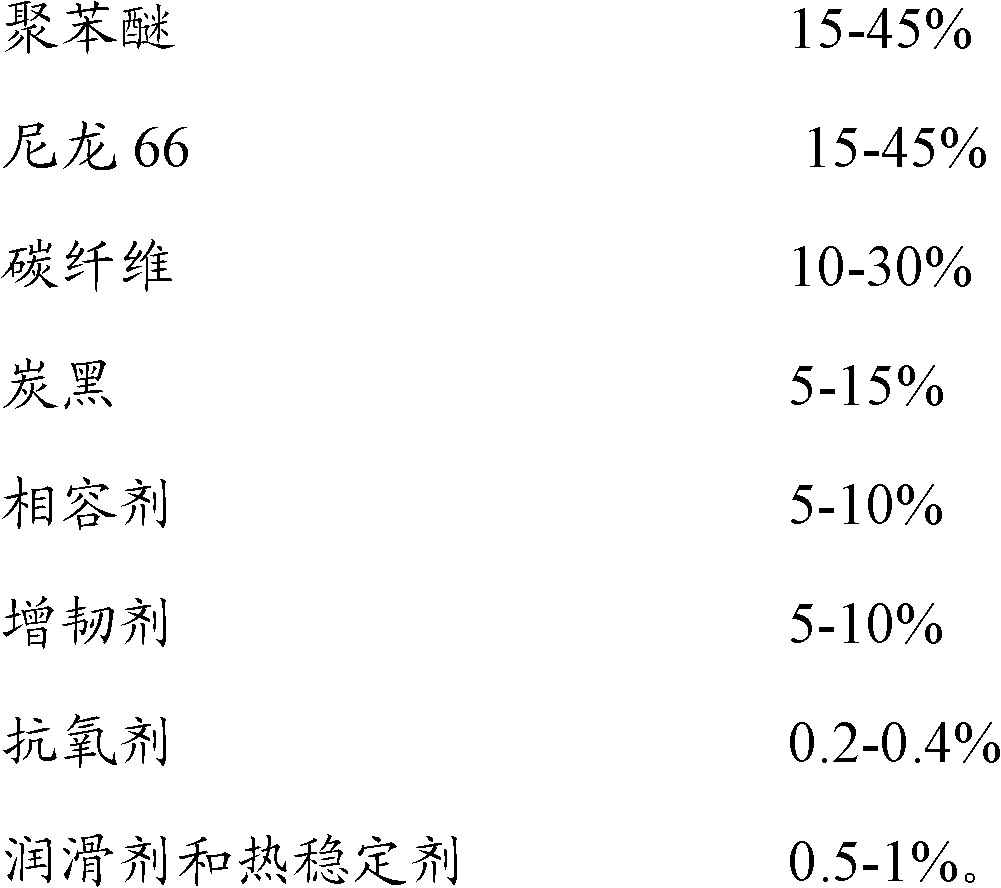

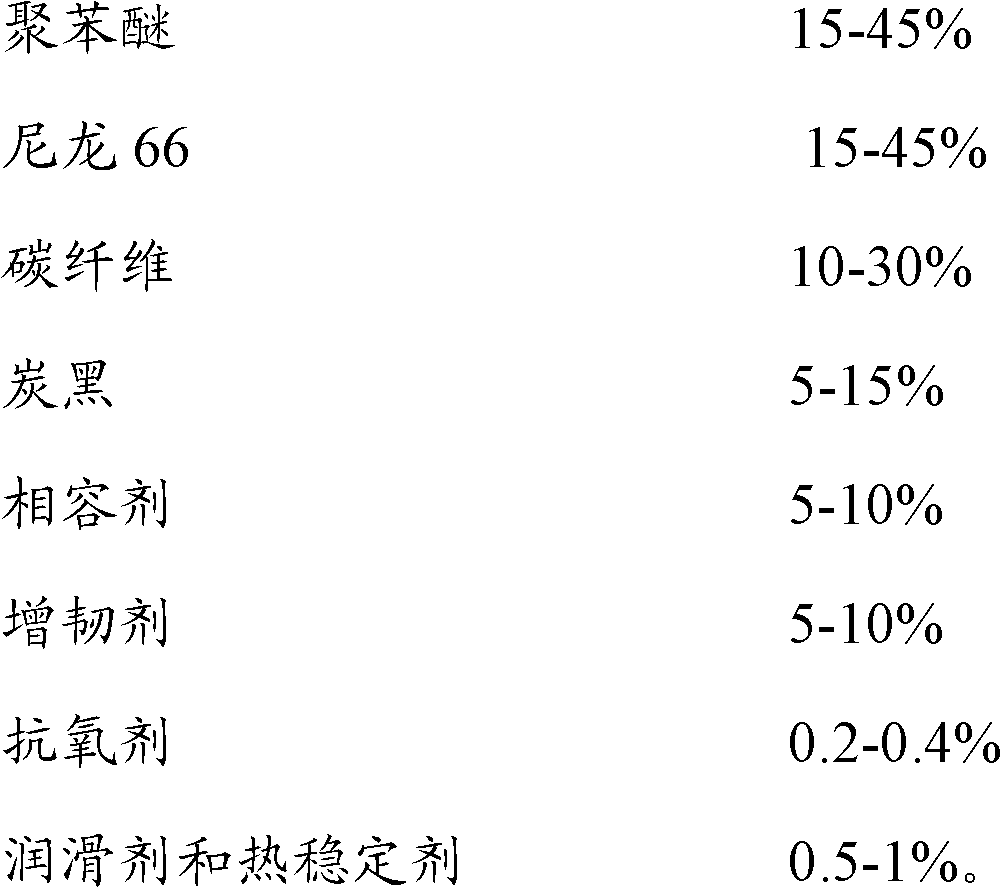

[0030] 15-45% by mass of polyphenylene ether, 15-45% by mass of nylon 66, 5-15% by mass of carbon black, 5-10% by mass compatibilizer, lubricant and heat stabilizer with a total mass percentage of 0.5-1%, toughener with a mass percentage of 5-10% and antioxidant with a mass percentage of 0.2-0.4% mix to get a mixture;

[0031] Step S02, extrusion processing

[0032] The mixture is extruded at a temperature of 220-260° C. to obtain a PPO / PA66 alloy material. In the extrusion treatment step, carbon fibers with a mass percentage of 10-30% are added.

[0033] Specifically, in step S01,

[0034] The polyphenylene ether used in the embodiment of the present invention has a viscosity of 0.35-0.5 dl / g, and there is no other limitation. The chemical name of the polyphenyle...

Embodiment 1

[0050] The preparation method of the PPO / PA66 alloy material of the embodiment of the present invention comprises the following steps:

[0051] Mixing 40% by mass of PPO, 20% by mass of PA66, 7% by mass of PPO-g-MAH and 7% by mass of SEBS-g-MAH, Stir well;

[0052] Then add the carbon black that the mass percentage composition is 5%, the mass percentage composition is 0.2% 1010 and the 168 that the mass percentage composition is 0.2%, the mass percentage composition is the lubricant of 0.5% and the mass percentage composition is 0.1% heat stabilizer, stir evenly to obtain a mixture;

[0053] Add the mixture into the hopper of the twin-screw extruder, add 20% carbon fiber into the extruder through the side feeding hopper, melt and blend, extrude and granulate to form PPO / PA66 alloy material , Among them, the temperature of each heating zone of the screw extruder is as follows: first zone temperature: 230°C; second zone: 240°C; third zone: 260°C; fourth zone: 250°C; machine he...

Embodiment 2

[0055] The preparation method of the PPO / PA66 alloy material of the embodiment of the present invention comprises the following steps:

[0056] Mixing 20% by mass of PPO, 40% by mass of PA66, 7% by mass of PPO-g-MAH and 7% by mass of SEBS-g-MAH, Stir well;

[0057] Then add the carbon black that the mass percentage composition is 5%, the mass percentage composition is 0.2% 1010 and the mass percentage composition is 0.2% 168, the mass percentage composition is the lubricant of 0.1% and the mass percentage composition is 0.9 % heat stabilizer, stir evenly to obtain a mixture;

[0058] Add the mixture into the hopper of the twin-screw extruder, add 20% carbon fiber into the extruder through the side feeding hopper, melt and blend, extrude and granulate to form PPO / PA66 alloy material , Among them, the temperature of each heating zone of the screw extruder is as follows: first zone temperature: 230°C; second zone: 240°C; third zone: 260°C; fourth zone: 250°C; machine head: 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com