Method for food packaging

A food and glue application technology, which is applied in the field of packaging food, can solve the problems of tape wrinkles and uneven shear force, and achieve the effect of preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for packaging food comprising the steps of:

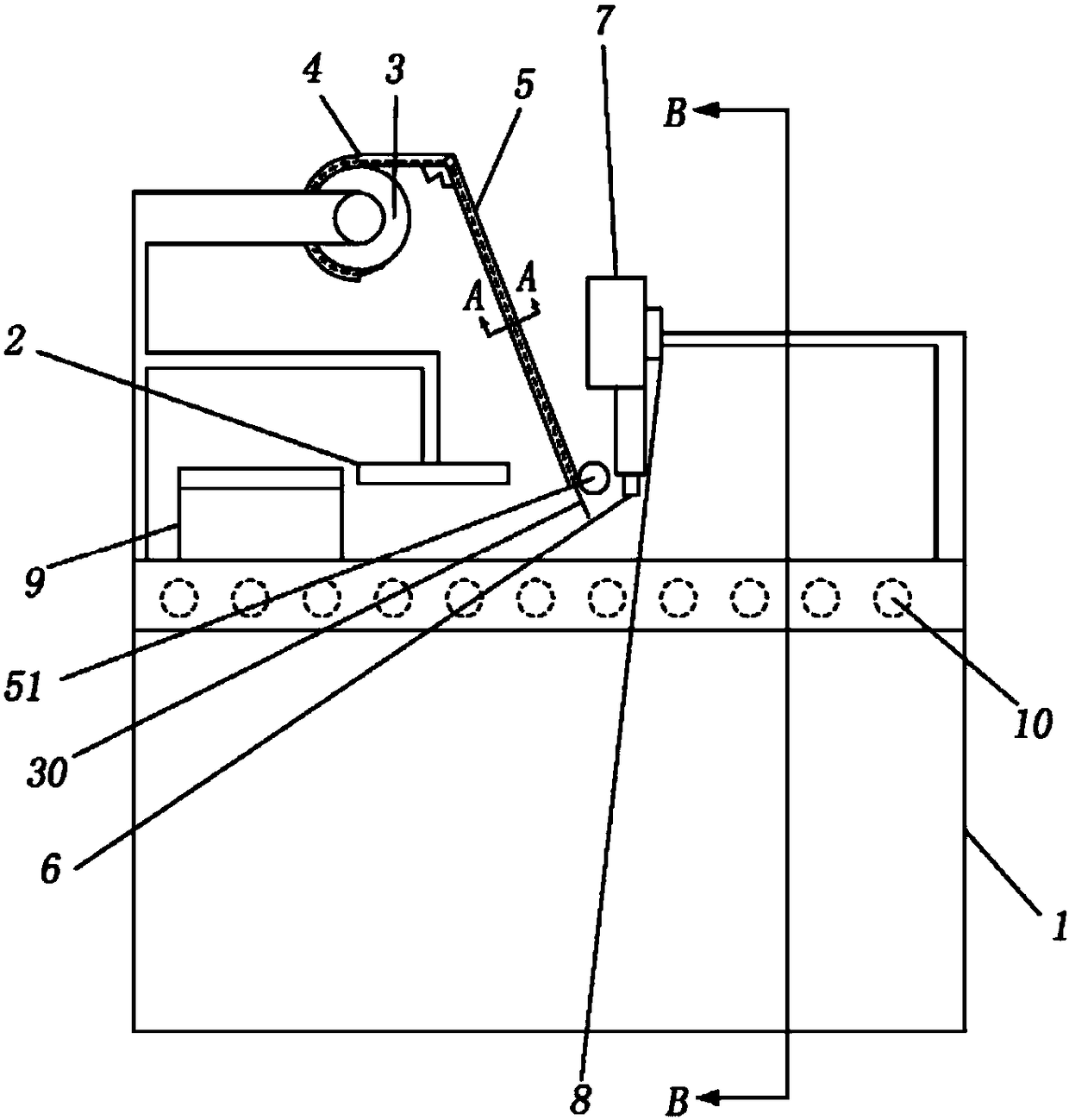

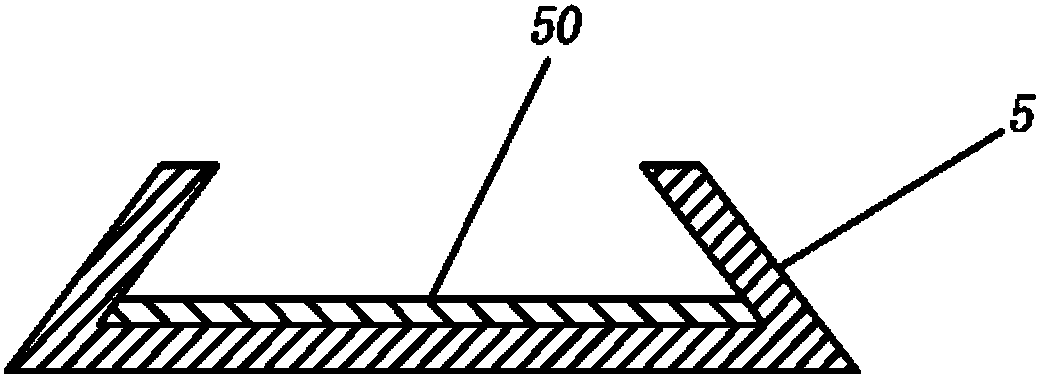

[0027] Step 1, preparation: prepare a frame 1, install the conveying roller 10 on the frame 1, install the flattening unit, the gluing unit and the cutting unit successively above the frame 1, the gluing unit includes the adhesive tape 30, and the cutting unit includes The conveyor belt 7 and the cleaning box 8 that are all fixed on the frame 1; Figure 4 As shown, one side of the conveyor belt 7 is fixedly connected to the cutter 6, and the blade direction of the cutter 6 is parallel to the width direction of the adhesive tape 30, and a cleaning area 82 for cleaning the cutter 6 is formed in the cleaning box 8, and the cleaning box 8 is equipped with Has a concentration of 38% alcohol.

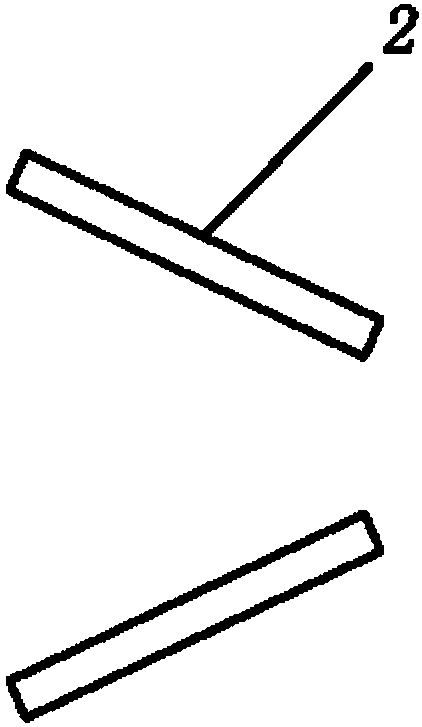

[0028] The specific structure is as figure 1 As shown: the flattening unit includes two eight-shaped flattening rods 2, and the two flattening rods 2 are fixed on the frame 1; the distance between the two flattening rods 2 near t...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is that the alcohol is replaced by acetone with a concentration of 35%. The rotational speed of the conveying roller 10 was 150 r / min. The distance between the two flattening rods 2 near the end of the gluing unit is 5 cm, and the distance between the two flattening rods 2 away from the end of the gluing unit is 8 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com