Automobile rear seat cushion and its processing and assembling method

A seat cushion and rear row technology, which is applied in the field of automobile rear seat cushion and its processing and assembly, can solve the problems of not particularly high safety level, difficult crash test requirements, and low safety performance level, so as to improve safety level and NVH index , Improve the effect of collision safety indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

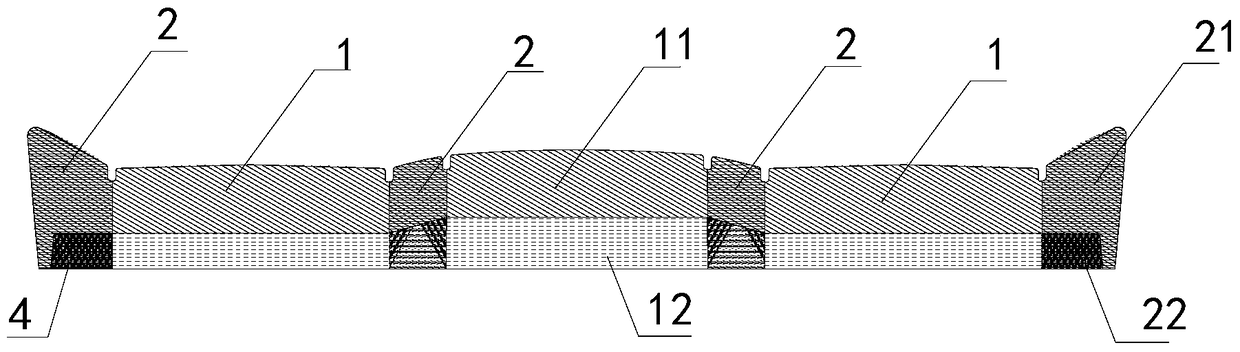

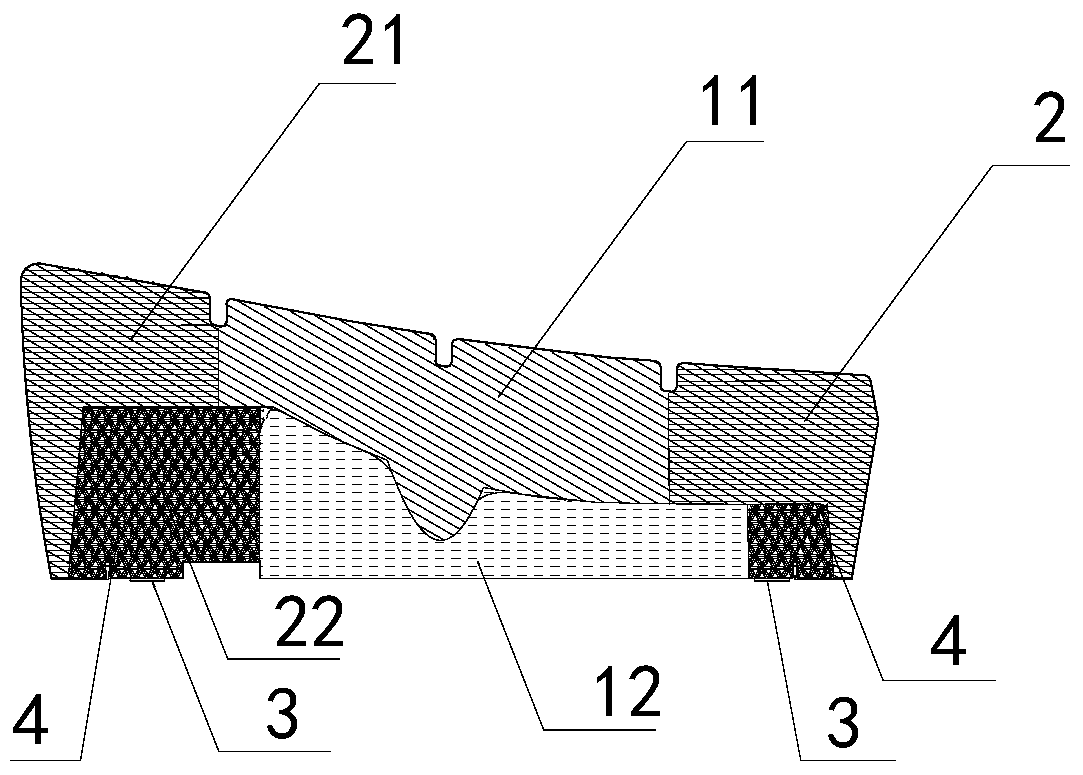

[0026] see figure 1 , figure 2 , the automobile rear seat cushion of the present invention, comprises sitting people area 1 and surrounding area 2, and each area all comprises cushion core and seat skin (seat skin is not shown); The seat cushion of sitting people area and surrounding area The core is composed of upper and lower layers of foam materials, and the upper and lower layers of foam materials are connected to each other through complementary structures (for coordination, see figure 2 ).

[0027] The upper layer 11 of the cushion core in the sitting area 1 is a low-density polyurethane foam material, and the lower layer 12 is a straw-shaped hollow polypropylene foam material with breathable and sound-absorbing functions. The density of the above-mentioned low-density polyurethane foam material is 50kg / m 3 .

[0028] The upper layer 21 of the cushion core in the surrounding area 2 is a high-density polyurethane foam material, and the lower layer 22 is a high-stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com