Integrated workbench used for model assembling and combining machining

A combined processing and integrated technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of scattered assembly model tools, low use efficiency, need to switch back and forth, etc., to achieve the effect of improving processing efficiency and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

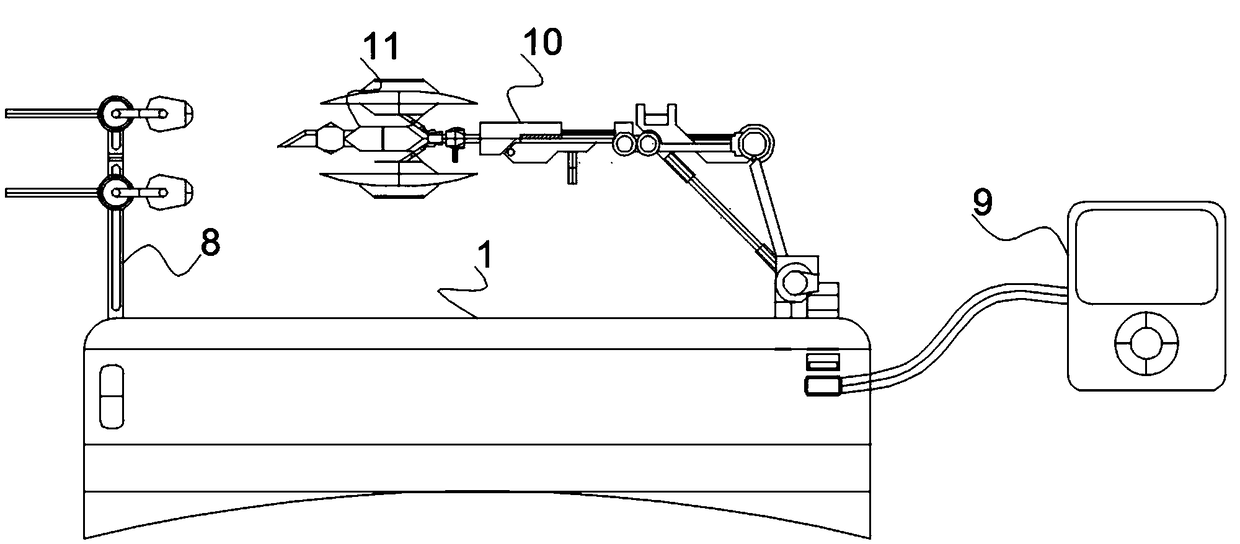

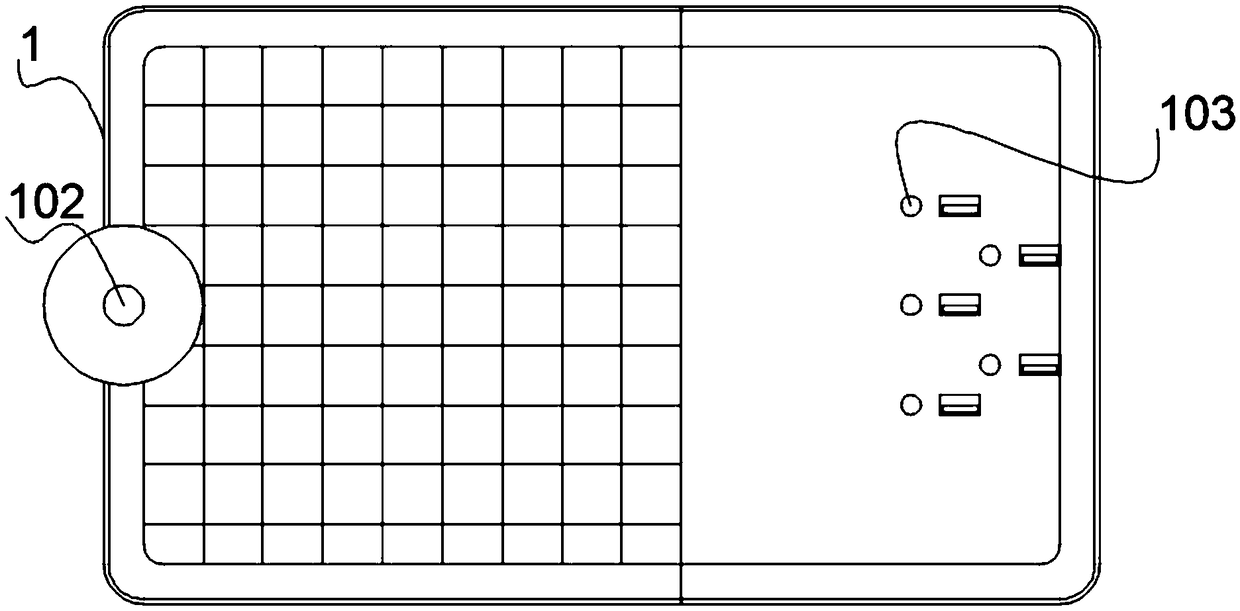

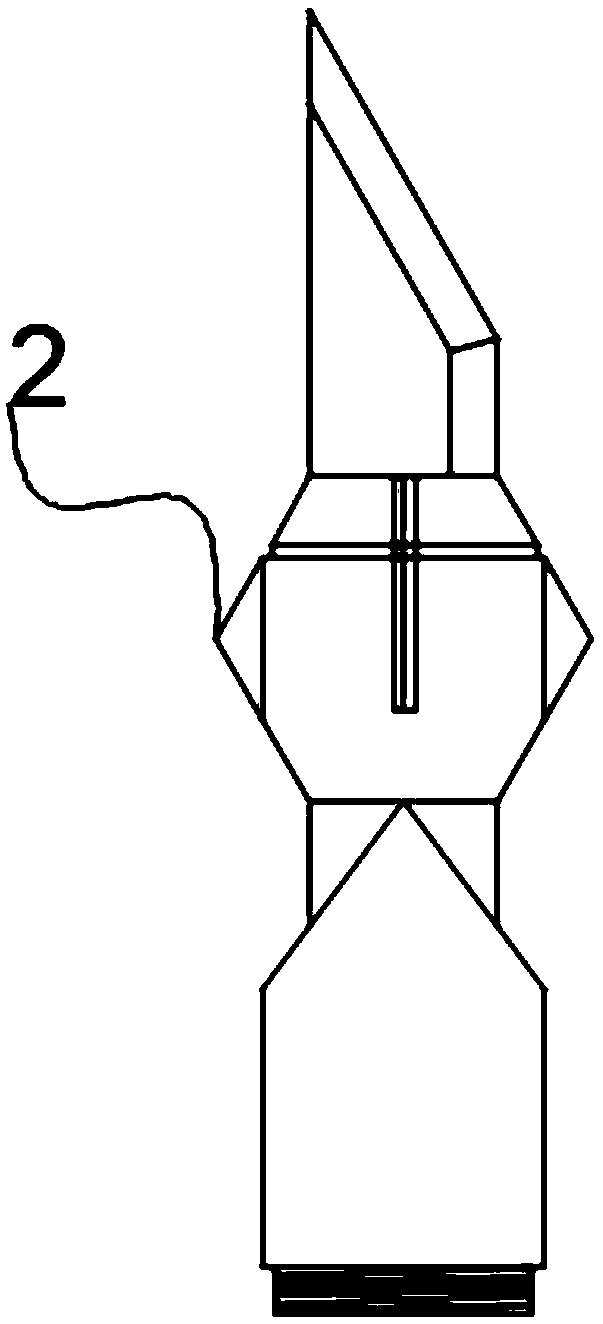

[0037] as attached figure 1 to attach Figure 10 Shown:

[0038] The present invention provides an integrated workbench for model assembling and combined processing, comprising a platform 1, a first pen knife 2, a second pen knife 3, scissors 4, a grinding block 5, a hand drill 6, tweezers 7, clamps Get the fixed arm 8, the plug-in control panel 9, the mechanical arm 10 and the manipulator 11; the platform 1, the fixed arm 8 and the mechanical arm 10 are the three main parts of the personal workbench; the front end of the mechanical arm 10 is equipped with a The pliers-shaped manipulator 11 that opens and closes left and right; the inside of the manipulator 11 is provided with screw holes, and the manipulator 11 is connected and installed with the first pen knife 2, the second pen knife 3 and the hand drill 6 through the screw holes; the left and right sides of the manipulator 11 A bolt hole is respectively installed at the end of the pliers, and the manipulator 11 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com