Measuring method and device for mechanical strength of granular sludge

A granular sludge and mechanical strength technology, applied in the direction of weighing by removing certain components, can solve the problems of complex operation of the measurement method and high test cost, and achieve easy measurement parameters, low test cost, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

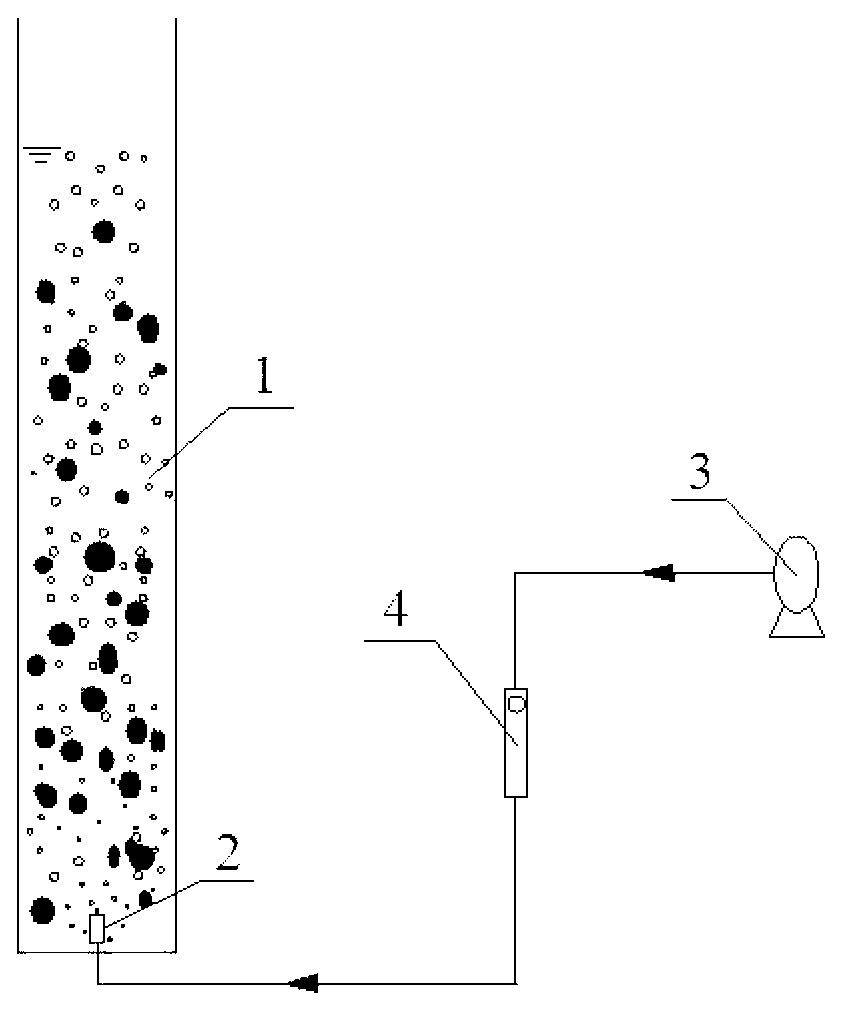

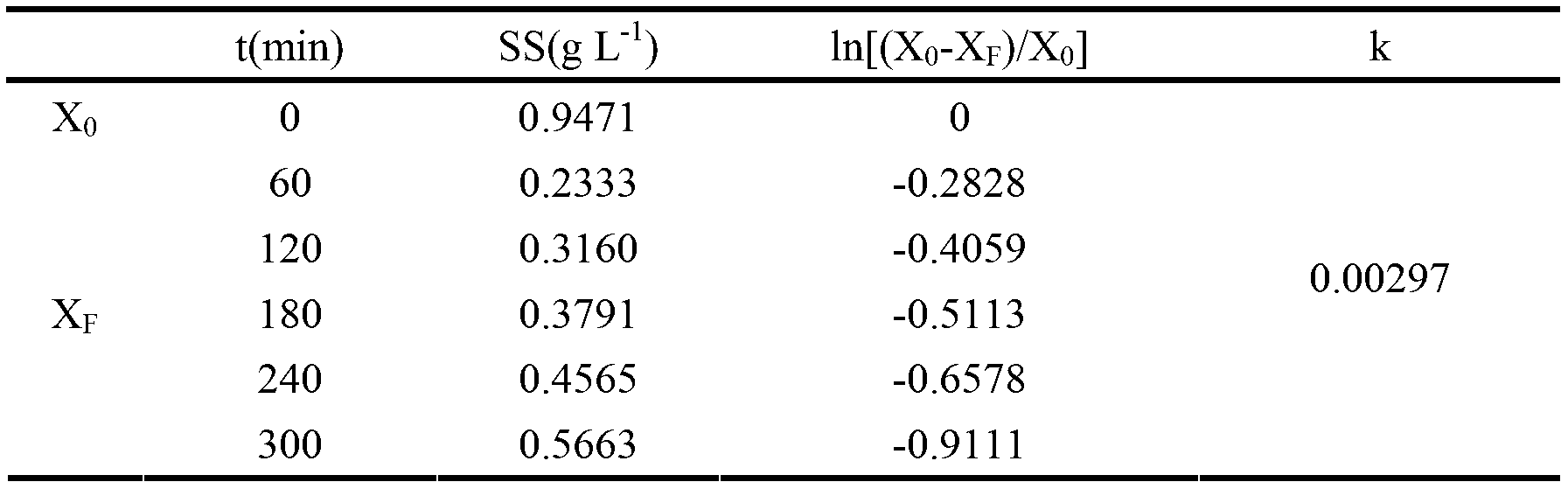

[0020] Embodiment 1: refer to figure 1 According to the measuring method and measuring device of the present invention, the mechanical strength of the anammox granular sludge is measured, specifically as follows: (1) take 50g of the anammox granular sludge to be tested, and use a screening device Screen out granular sludge with a particle size of less than 0.2mm; (2) Add 1L of distilled water to the cylinder, where the cylinder has a height-to-diameter ratio of 5 and a volume of 1.4L, and the particle size obtained in step (1) is greater than 0.2 mm of granular sludge is mixed into distilled water; (3) Turn on the air compressor, adjust the air flow meter to control the aeration rate to 160L / h, and the gas can be evenly distributed through the microporous air distribution device at the bottom of the cylinder, so that the inside of the cylinder The shear force of the granular sludge is the same, and the granular sludge in the cylinder is fully mixed with distilled water to form...

Embodiment 2

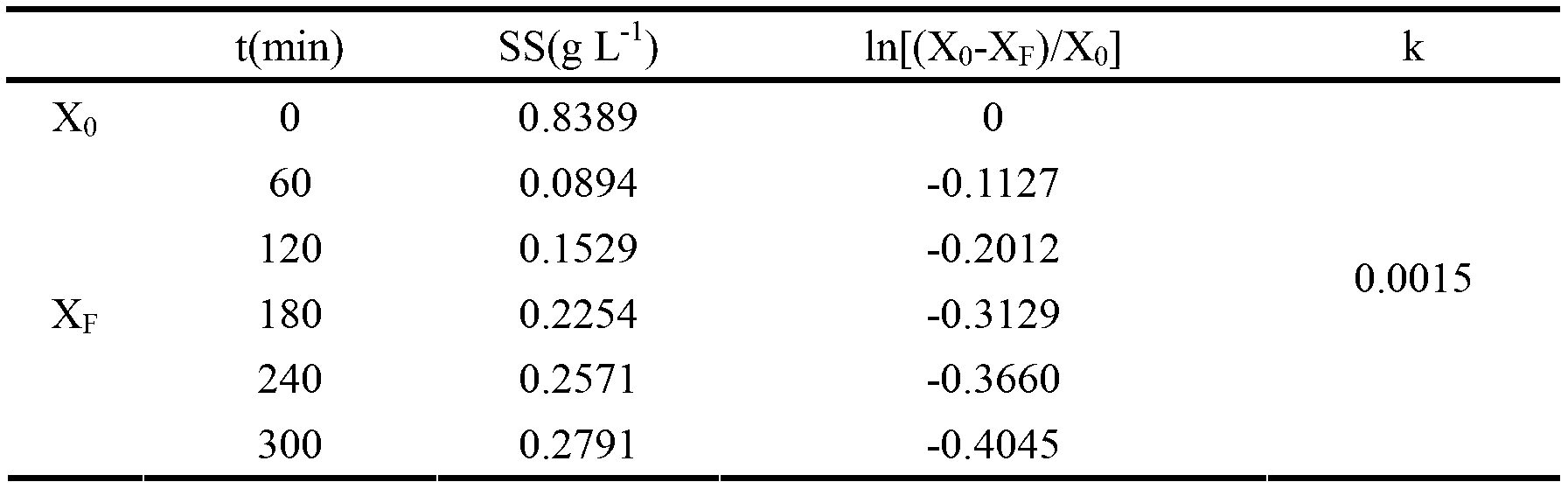

[0023] Embodiment 2: refer to figure 1 According to the measuring method and measuring device of the present invention, the mechanical strength of the methanogenic granular sludge was measured, specifically as follows: (1) Take 30 g of the methanogenic granular sludge to be tested, and use a screening device to screen out the particle size Granular sludge smaller than 0.2mm; (2) Add 1L of distilled water into the cylinder, wherein the cylinder has a height-to-diameter ratio of 5 and a volume of 1.4L, and the granular sludge with a particle size greater than 0.2mm obtained in step (1) Mix the mud into distilled water; (3) Turn on the air compressor, adjust the air flow meter to control the aeration rate to 200L / h, and the gas can be evenly distributed through the microporous air distribution device at the bottom of the cylinder, so that the granular sludge in the cylinder Under the same shear force, the granular sludge in the cylinder is fully mixed with distilled water to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com