Structure that includes bolt fastening portion having higher resistance against external force

A structure and bolt technology, applied in the field of structures, can solve problems such as exceeding the friction retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

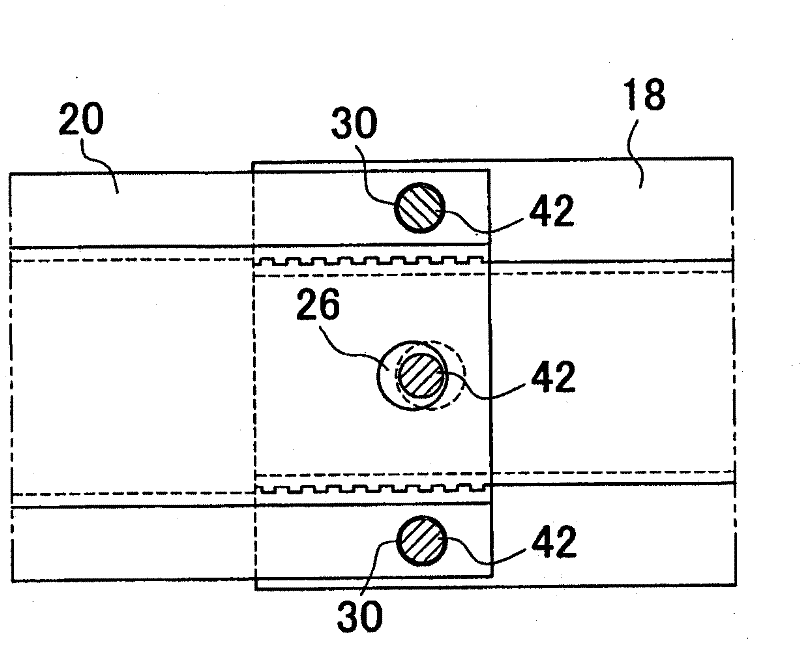

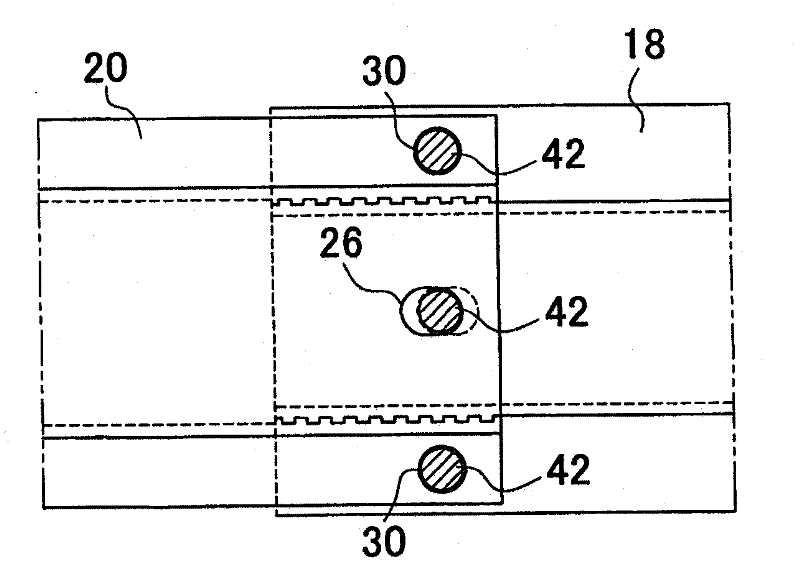

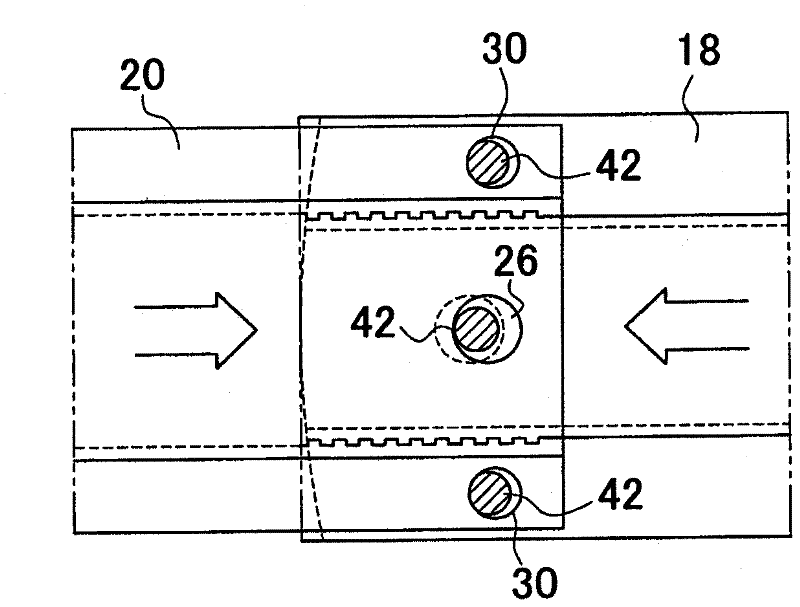

[0027] image 3 is a perspective view of an example of a floor cross member and a roof cross member of an automobile body attached at one end to a side frame of the vehicle body according to the present invention. Such as image 3 As shown, the vehicle body includes side frames 10 , a pair of center pillars 12 , floor rails 14 and roof rails 16 . Center pillars 12 are provided individually on the left and right sides of the vehicle. Each end of the floor cross member 14 is attached to the lower ends of the left and right center pillars 12 ( image 3 Only one of the center columns is shown). Also, each end of the roof cross member 16 is attached to the upper ends of the left and right center pillars 12, respectively.

[0028] The floor beam 14 includes a central portion 18 forming a central portion of the floor beam 14 and a gusset 20 attached to each end of the floor beam 14 . image 3 Only one of the gussets 20 attached to the ends of the floor beams 14 is shown. As in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com