Cutting mold for heat shield of automobile exhaust system

A technology of automobile exhaust system and trimming die, which is applied in the stamping and forming of automobile exhaust system parts and the forming field of automobile parts, can solve the problems of cracking and easy wrinkling of workpieces, so as to ensure reliable cutting and ensure Process quality, avoid wrinkling or even cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

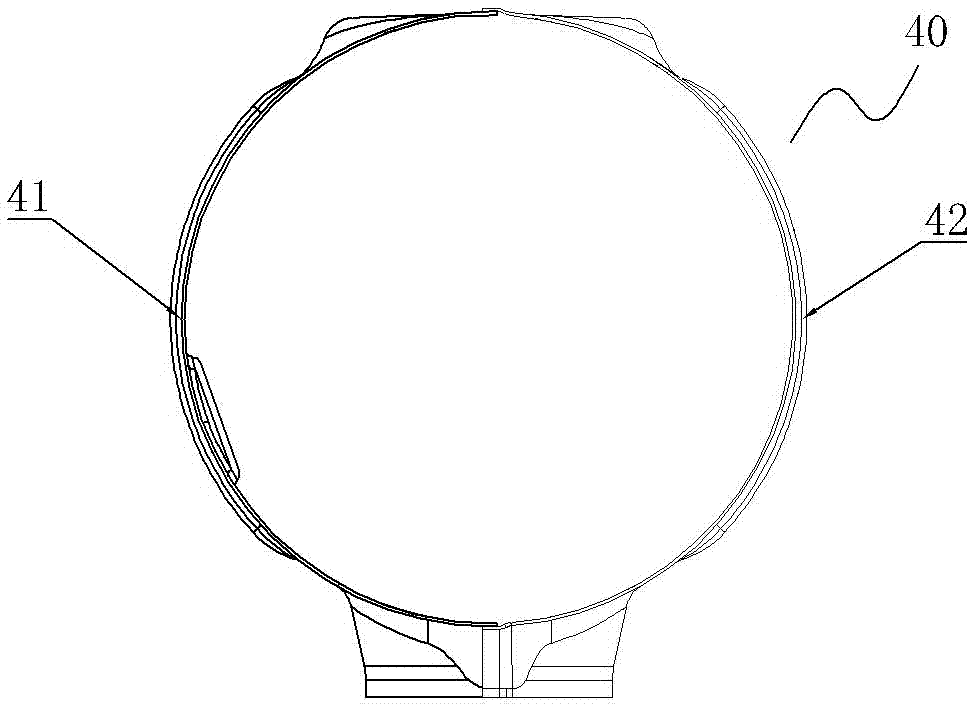

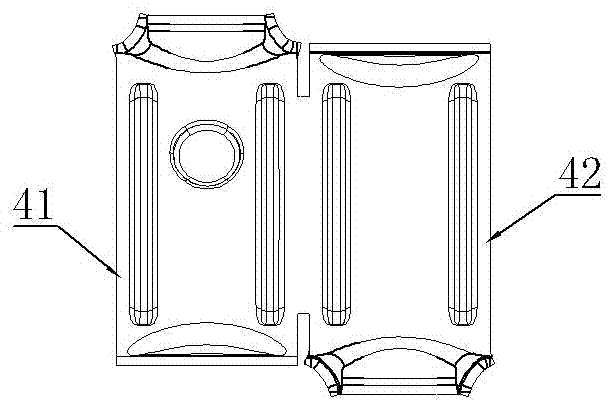

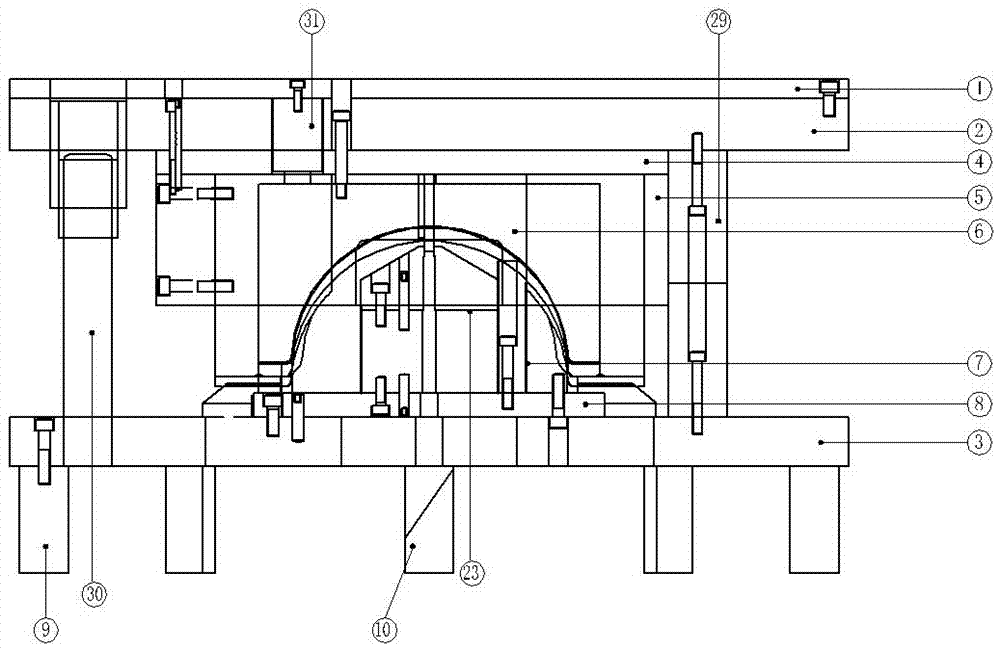

[0016] See image 3 , Figure 4 and Figure 5 , the mold of the present invention includes an upper mold structure and a lower mold structure, the upper mold structure and the lower mold structure are guided by a rolling guide mechanism 30 for mold clamping, the upper mold structure includes an upper template 2, and the bottom surface of the upper template 2 is installed through an upper backing plate 4 There is an upper fixed plate 5, and a binder plate 6 is installed in the upper fixed plate 5. The lower mold structure includes a lower template 3, and a punch 7 is installed on the lower template 3 through a lower backing plate 8. In the upper fixed plate 5, the binder A cutter insert assembly is installed around the plate 6, and the cutter insert assembly includes a second cutter insert 12, a fifth cutter insert 15, a sixth cutter insert, Part 16 and the third cutter insert 13, and the fourth cutter insert 14, the seventh cutter insert 17, the eighth cutter insert 18 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com