Pipe body uniform shear combination tool and working method thereof

A technology of combining knives and shearing knives, which is applied in the direction of knives, shearing devices, and pipe shearing devices used in shearing machines, can solve the problems of low reutilization rate of knives, difficulty in recycling, waste of resources, etc., and achieve improvement Cutting efficiency, less heat generation, and the effect of cutting tool costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

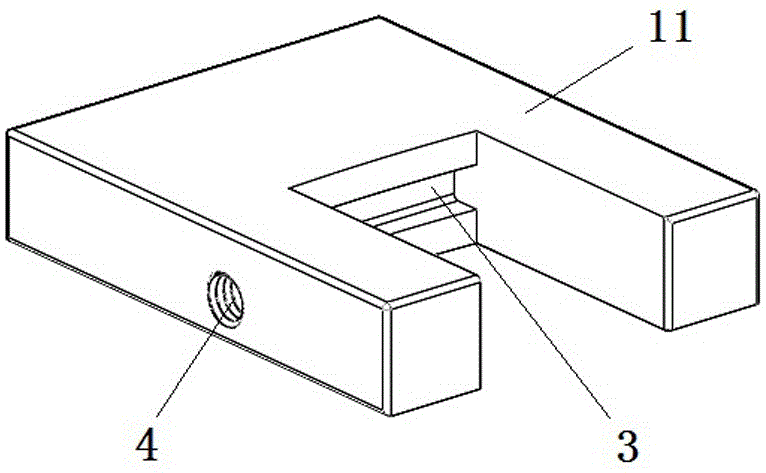

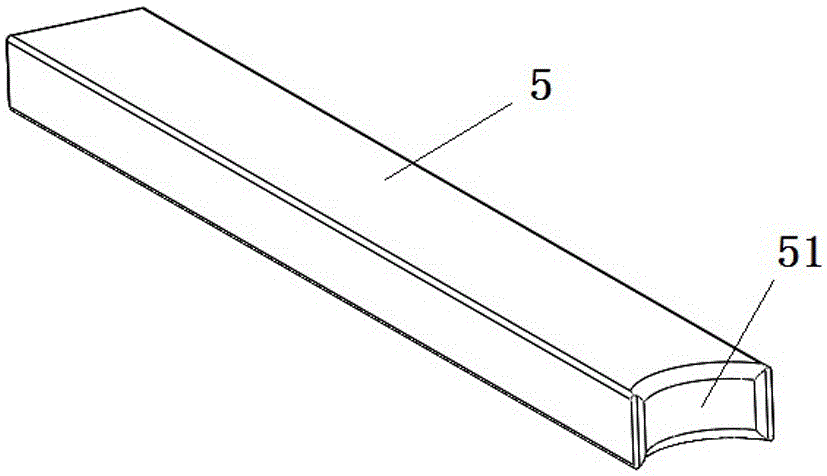

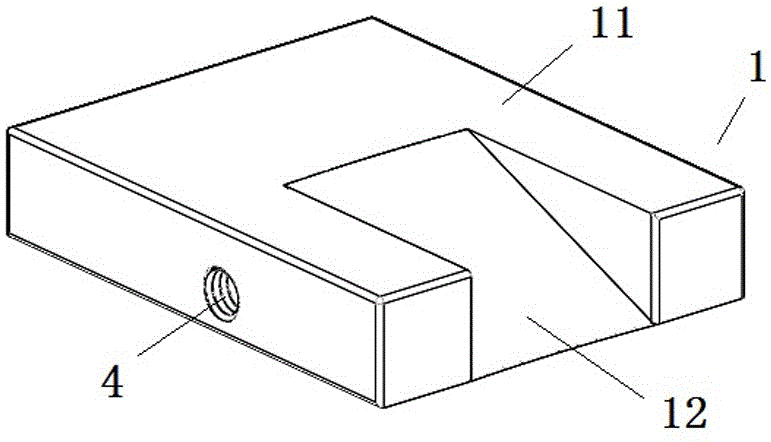

[0032] Such as Figure 1~8 As shown, a pipe body uniform shearing combined cutter includes an upper shearing knife 1 that can move up and down and a fixed lower shearing knife 2, and the upper shearing knife 1 includes an upper knife body 11 and an upper knife edge 12 , the lower shearing knife 2 comprises a lower cutter body 21 and a lower blade 22, and the upper blade 12 and the lower blade 22 all have arc-shaped edges; the upper cutter body 11 and the lower cutter body 21 have the same structure, and the The upper blade 12 has the same structure as the lower blade 22 .

[0033] In the embodiment of the present invention, the upper blade 12 is installed on the upper cutter body 11 through the installation groove 3 and fixedly connected by screws, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com