Roller bearing

一种滚子轴承、滚子的技术,应用在滚子轴承领域,能够解决滚子破损等问题,达到冷却效果提高、实现寿命、长寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

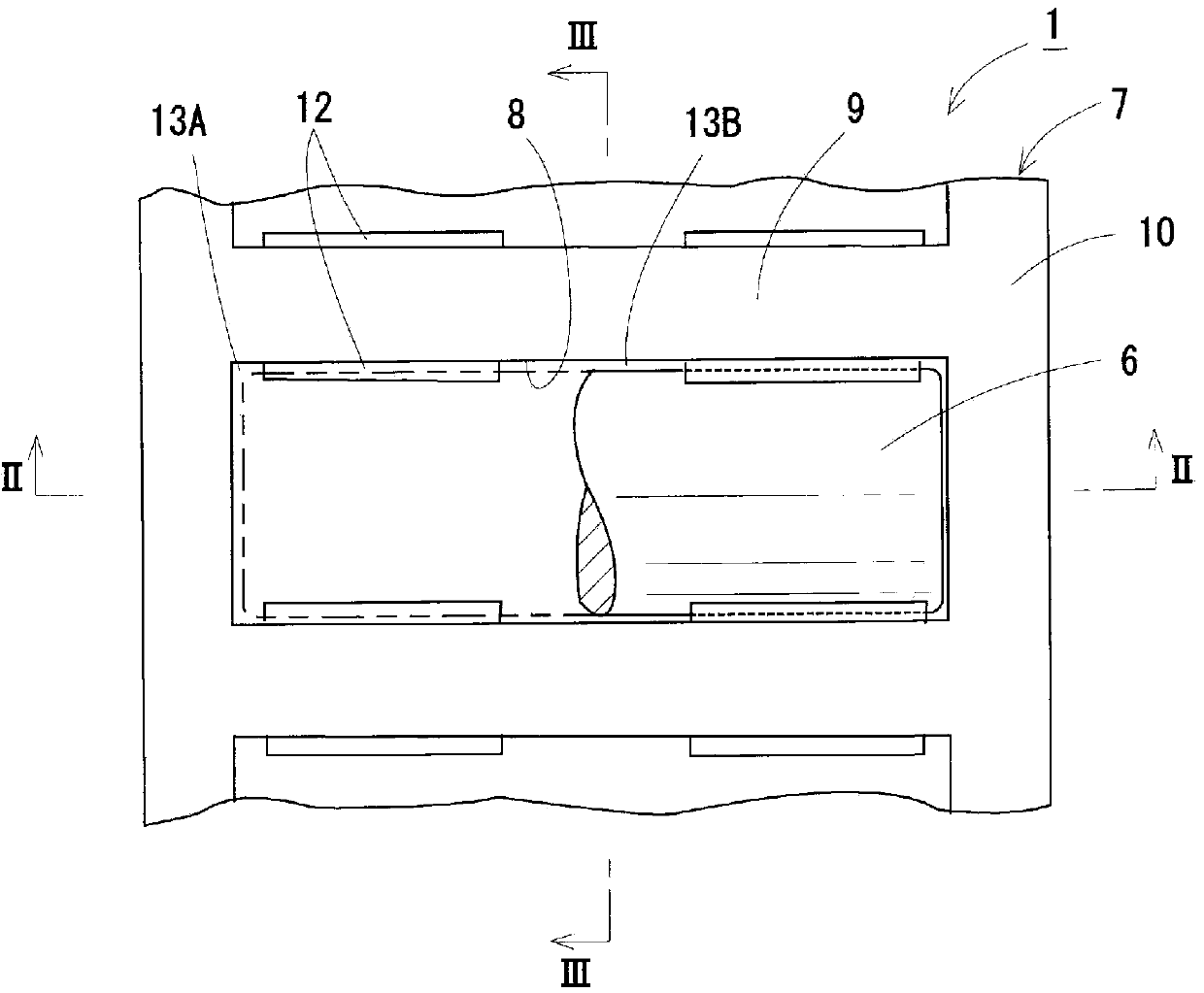

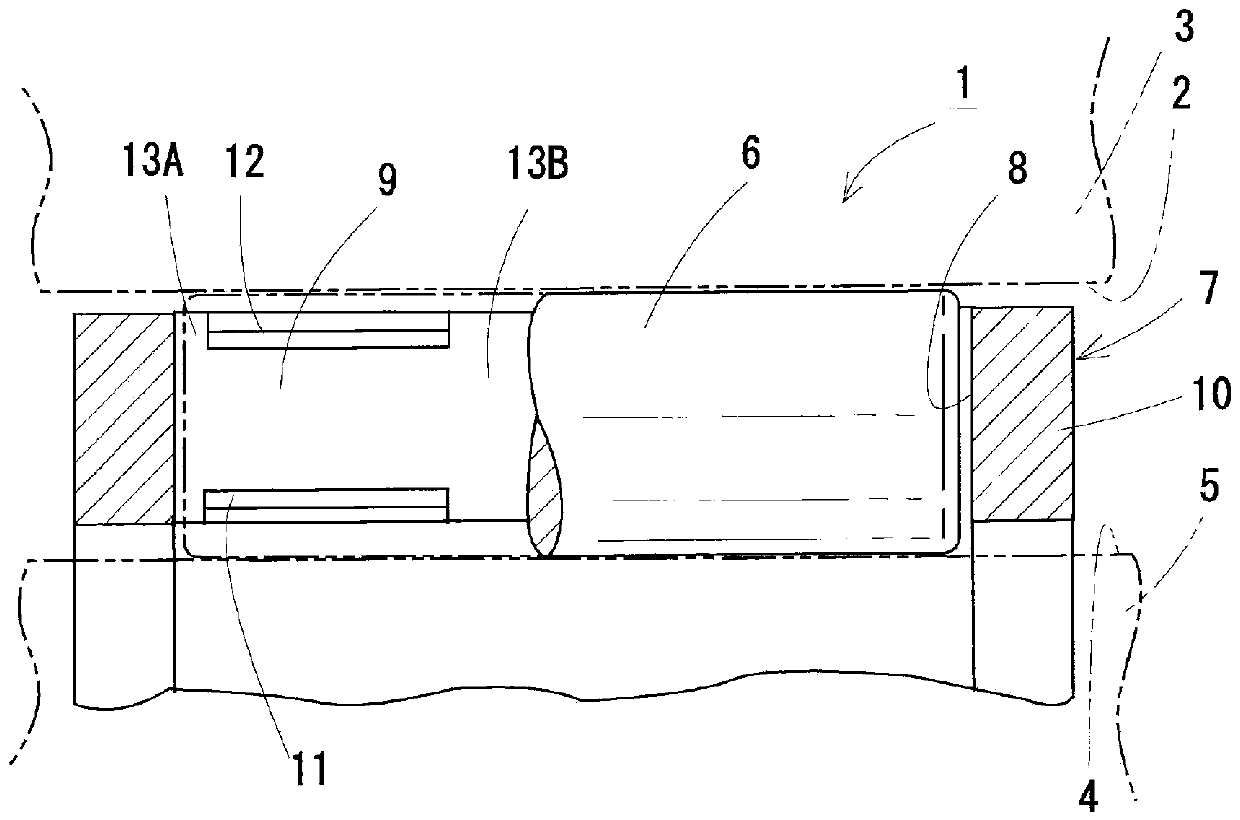

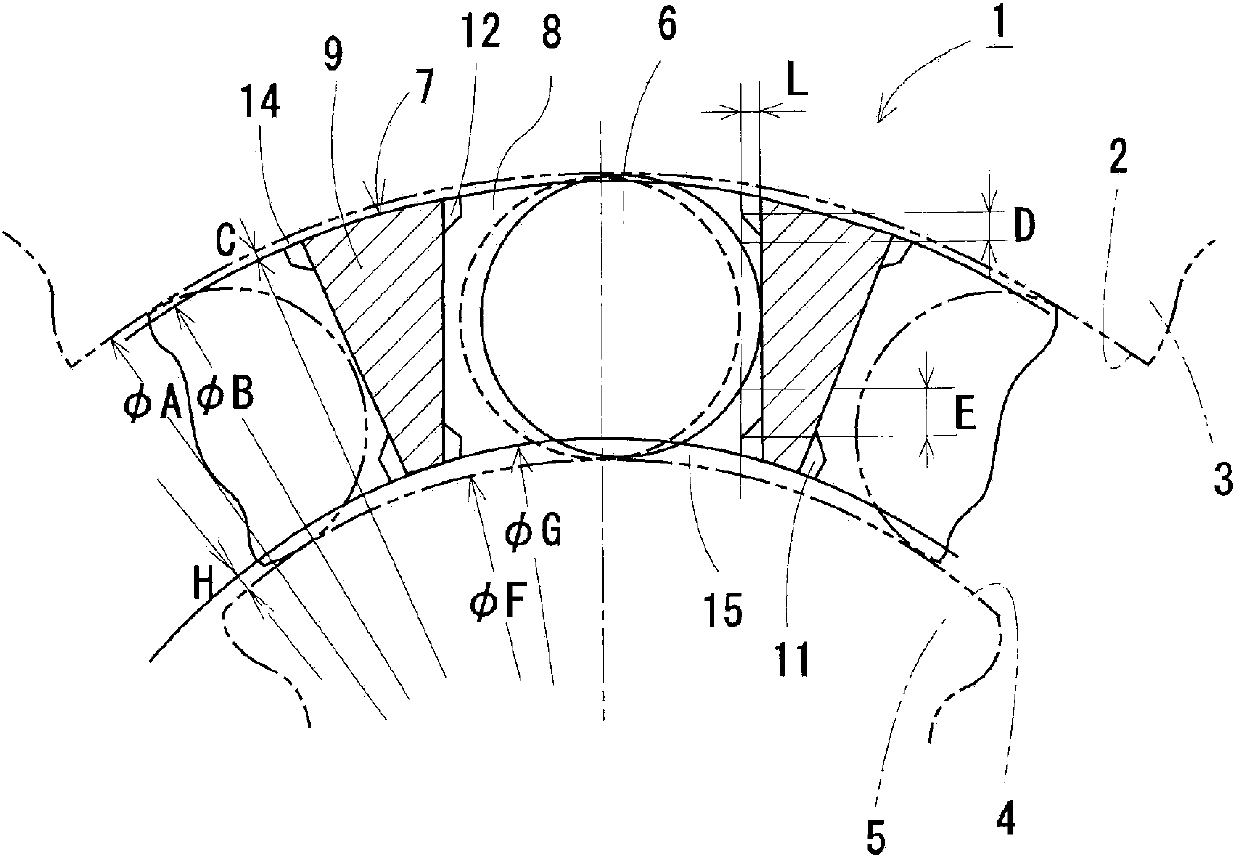

[0040] based on Figure 1 ~ Figure 4 Embodiments of the present invention will be described.

[0041] The roller bearing 1 includes: an outer member 3 having a cylindrical outer raceway 2 on the inner peripheral surface; an inner member 5 having a cylindrical inner raceway 4 on the outer peripheral surface; A plurality of rollers 6 are freely rotatably provided between the inner raceway 4 and the inner raceway 4 .

[0042] The rollers 6 are formed into cylindrical bodies made of a metal material or the like, and are configured in the form of needle rollers, cylindrical rollers, etc., and are regularly arranged and held in a cylindrical cage 7 as a whole.

[0043] The cage 7 has rectangular pockets 8 for regularly accommodating the rollers 6 at predetermined intervals in the circumferential direction, and is formed of a resin material by injection molding or the like. The cage 7 is formed so that the pockets 8 pass through from the inner diameter side to the outer diameter si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com