Electrical connector fretting wear detection system and method based on infrared thermography technology

An electrical connector, infrared thermal imaging technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as inability to perform real-time detection, sample damage, etc., and achieve the effect of saving sample consumption, fast speed, and continuous testing and testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

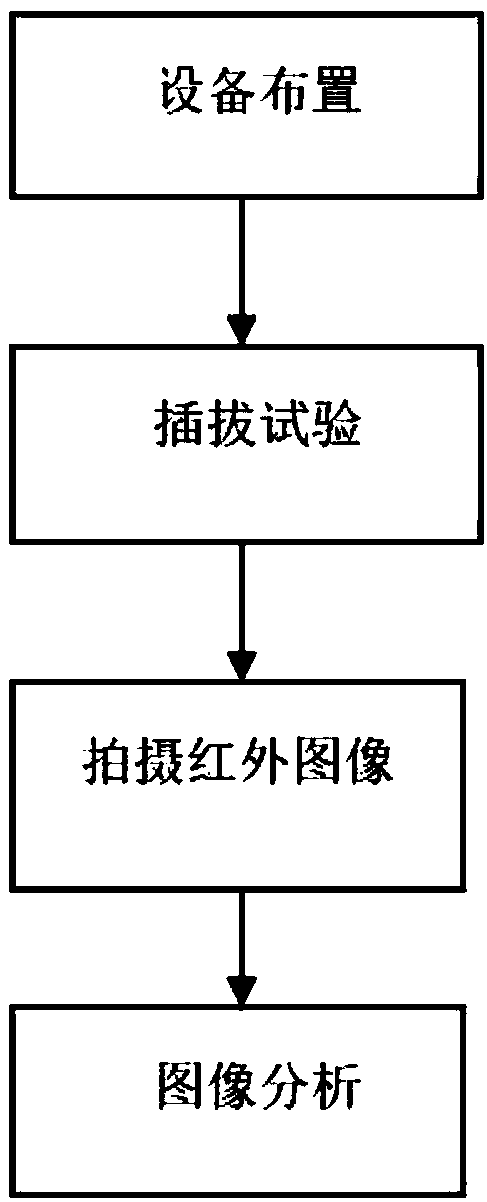

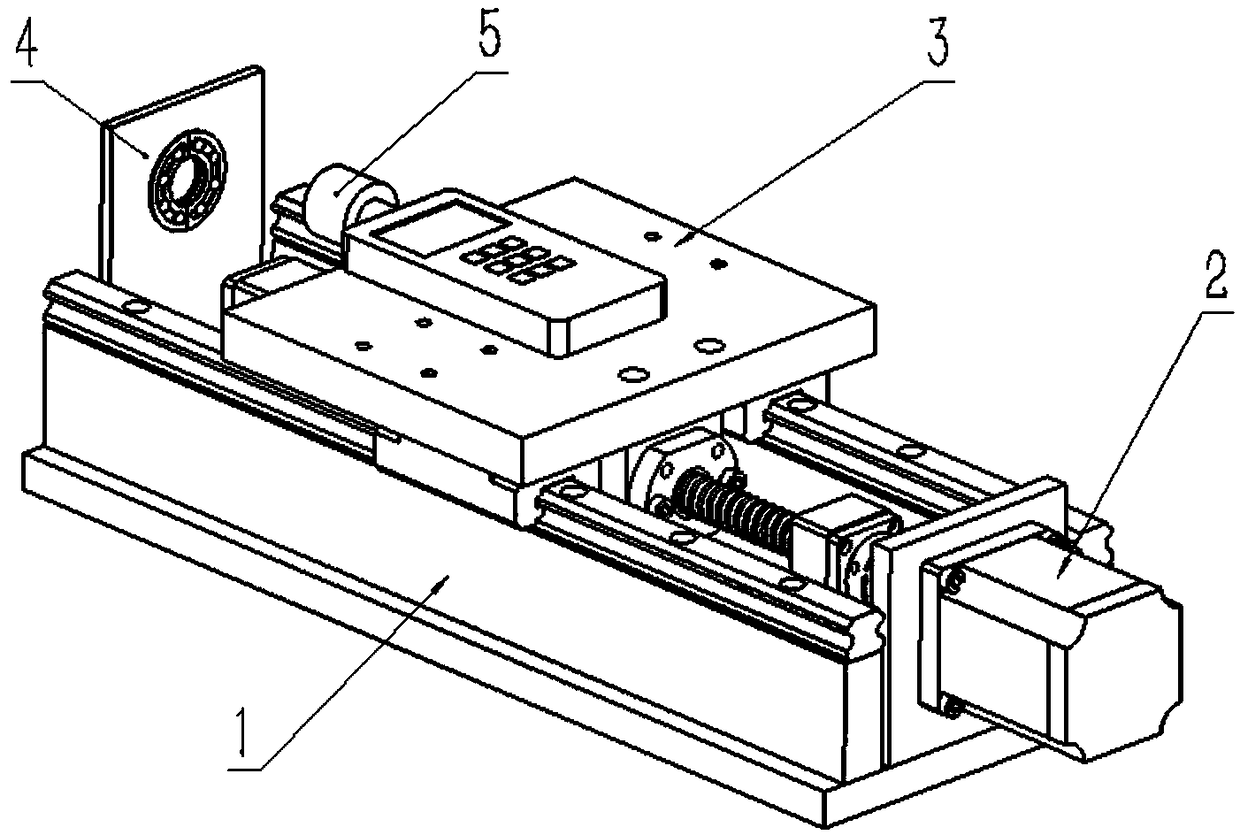

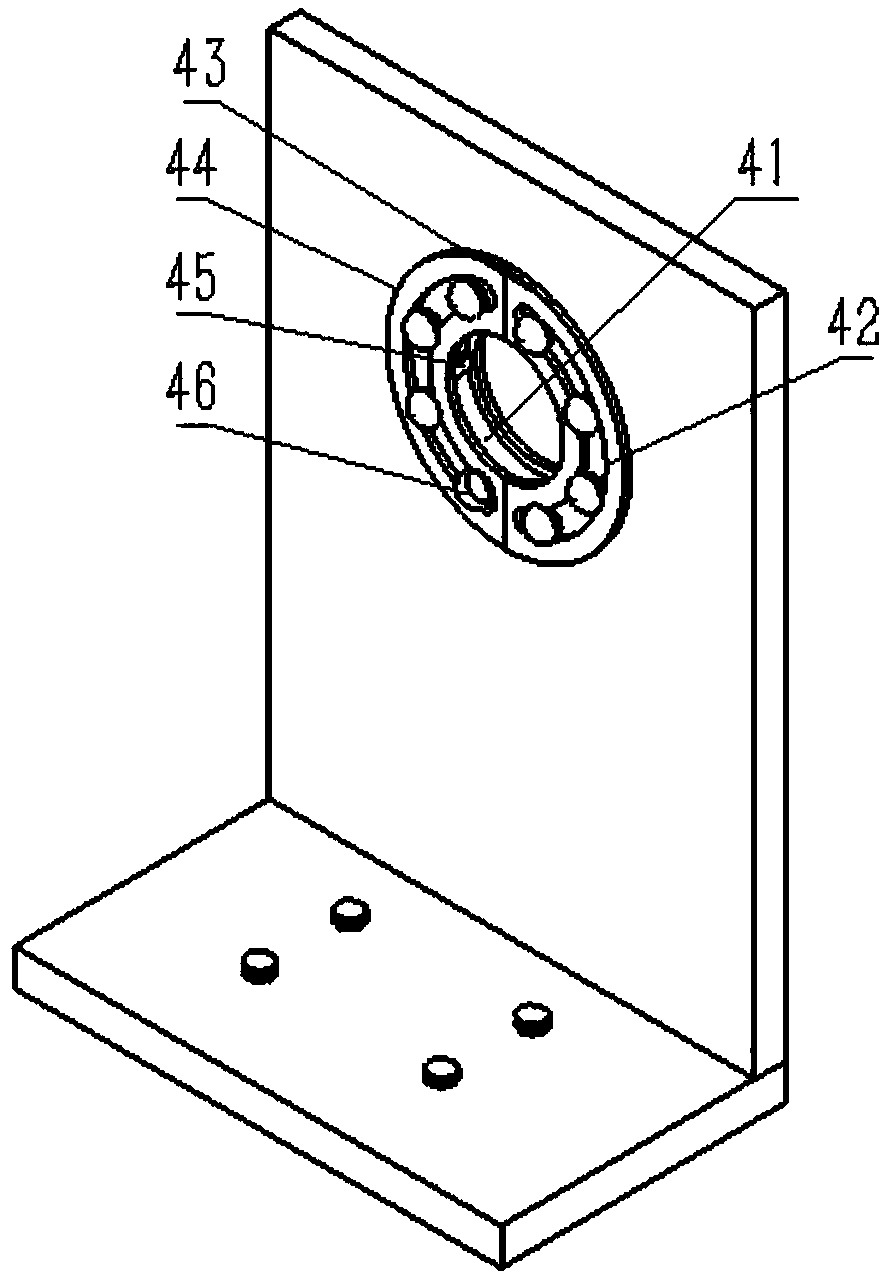

[0047] 1) Preparation of the tested part: Remove the metal shell of the electrical connector, saw off the black insulator outside one of the sockets of the electrical connector to expose a complete contact reed, and then in the contact reed that needs to be photographed Coat the surface with a layer of black ink and dry it or paste black tape, or put the thermal imaging camera and the electrical connector in the same dark box; weld the wires on the electrical connector after the above treatment, and confirm that the electrical connector has reached After the thermal equilibrium state, install the electrical connector on the plug-in device for plug-in test;

[0048] 2) Place the electrical connector being plugged and unplugged horizontally in front of the infrared thermal imager, connect the circuit, adjust the output current of the DC stabilized current source, and make the electrical connector reach a normal working state;

[0049] 3) During detection, set the parameters of t...

Embodiment 1

[0053] In this embodiment, the model of the thermal imaging camera is Shanghai Juge MAG13, and the thermal imaging processing software installed on the computer is ThermoX.

[0054] This embodiment provides a system and method for detecting fretting wear of electrical connectors based on infrared thermal imaging technology, and the specific implementation steps are as follows:

[0055] 1) Preparation of the tested part: The metal shell needs to be removed from the electrical connector, and about one-third of the black insulator outside one of the electrical connector jacks is sawed off to expose a complete contact reed, and then photographed when needed The surface of the contact reed is coated with a layer of black ink and dried; the electrical connector after the above treatment is welded to the wire, and after confirming that the electrical connector has reached a thermal equilibrium state, the electrical connector is installed on the plugging device for plugging. Pulling o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com