Production of optimized controllable arranged electroplating tool of three-dimensional abrasive laminated

A three-dimensional multi-layer and manufacturing method technology, applied in the field of mechanical processing and manufacturing, can solve the problems of grinding tool failure grinding heat, easy blockage and damage of the working surface of the grinding tool, and achieves improved grinding performance, good application prospects, and reduced manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention are described in detail below in conjunction with the technical solution and the drawings, and the specific implementation steps are as follows:

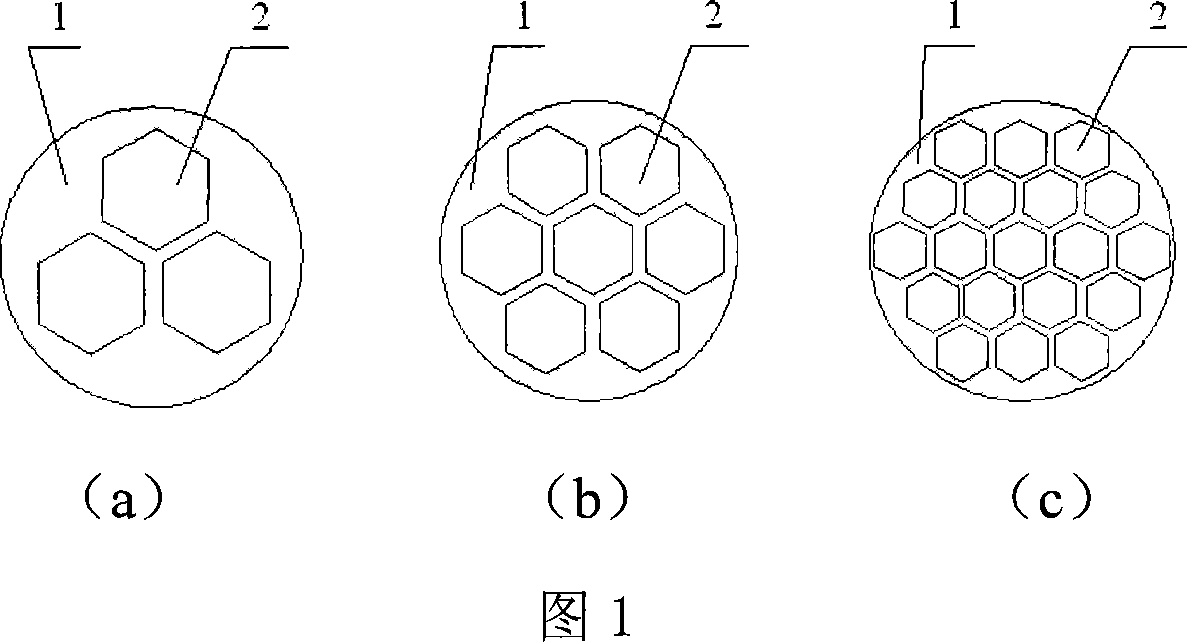

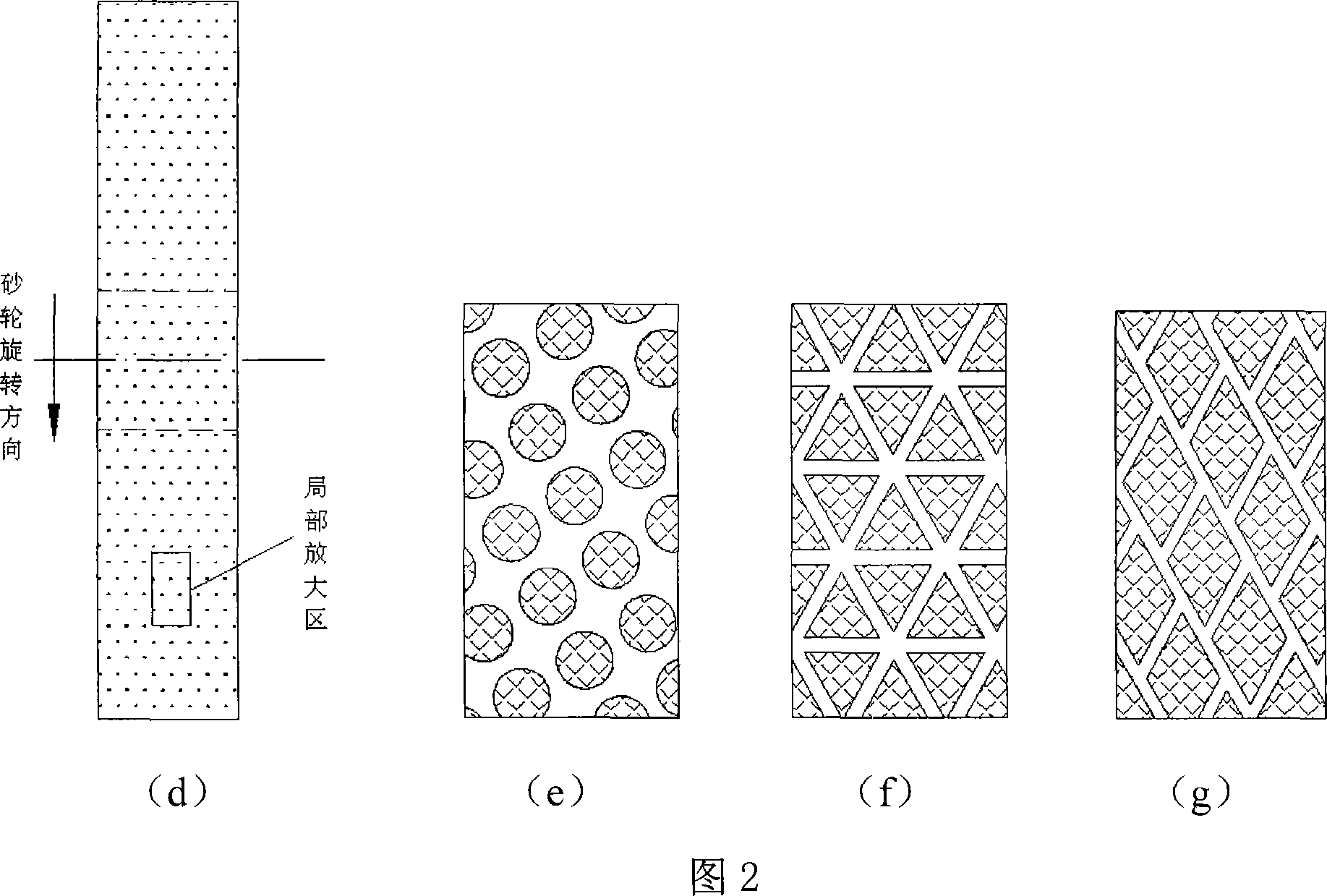

[0031] Step 1. For the processing object and processing parameters, select the abrasive particle size, and determine the geometric pattern of the micro-abrasive group and its area S by the optimization method of the present invention Gi , The grinding void ratio η and the number of electroplating layers n, and considering the direction of the processing track, determine the arrangement of the micro-abrasive groups.

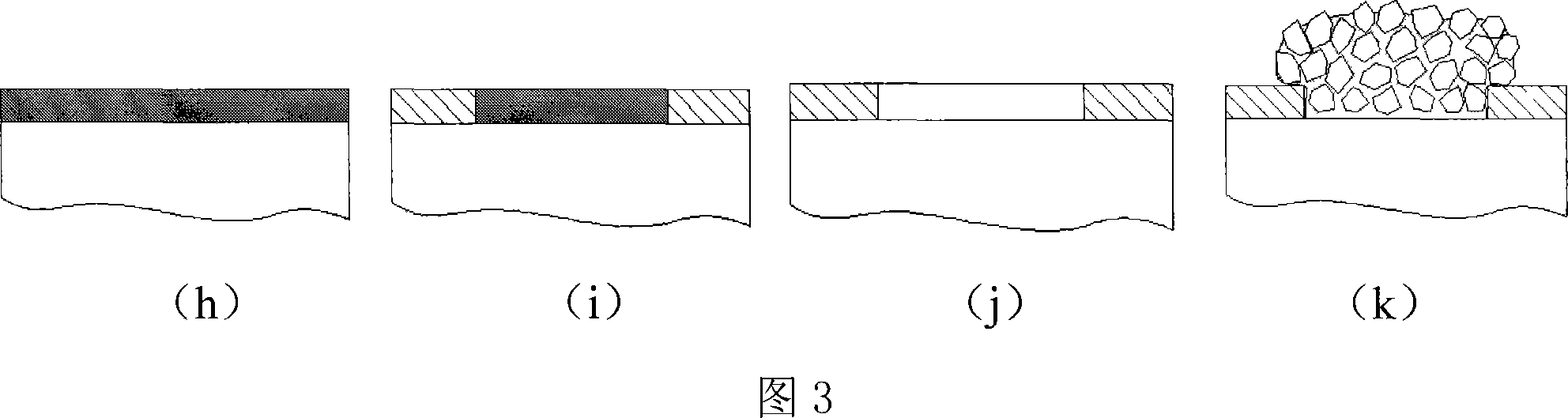

[0032] Step 2. The substrate undergoes the rust and oil removal process and the abrasive pre-treatment process for standby; the photo-engraving film is made according to the optimized design pattern. A layer of copper is grown on the substrate through a general copper electroplating process, the thickness of which is 3 to 5 times the abrasive grain size; a commerciall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com