Lubricant valve for oil pumps of internal combustion engines

A technology for lubricants and internal combustion engines, which is used in the pressure lubrication of lubricating pumps, controlling the pressure of lubricants, liquid fuel engines, etc., and can solve the problems of valve piston stuck, unsuitable, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

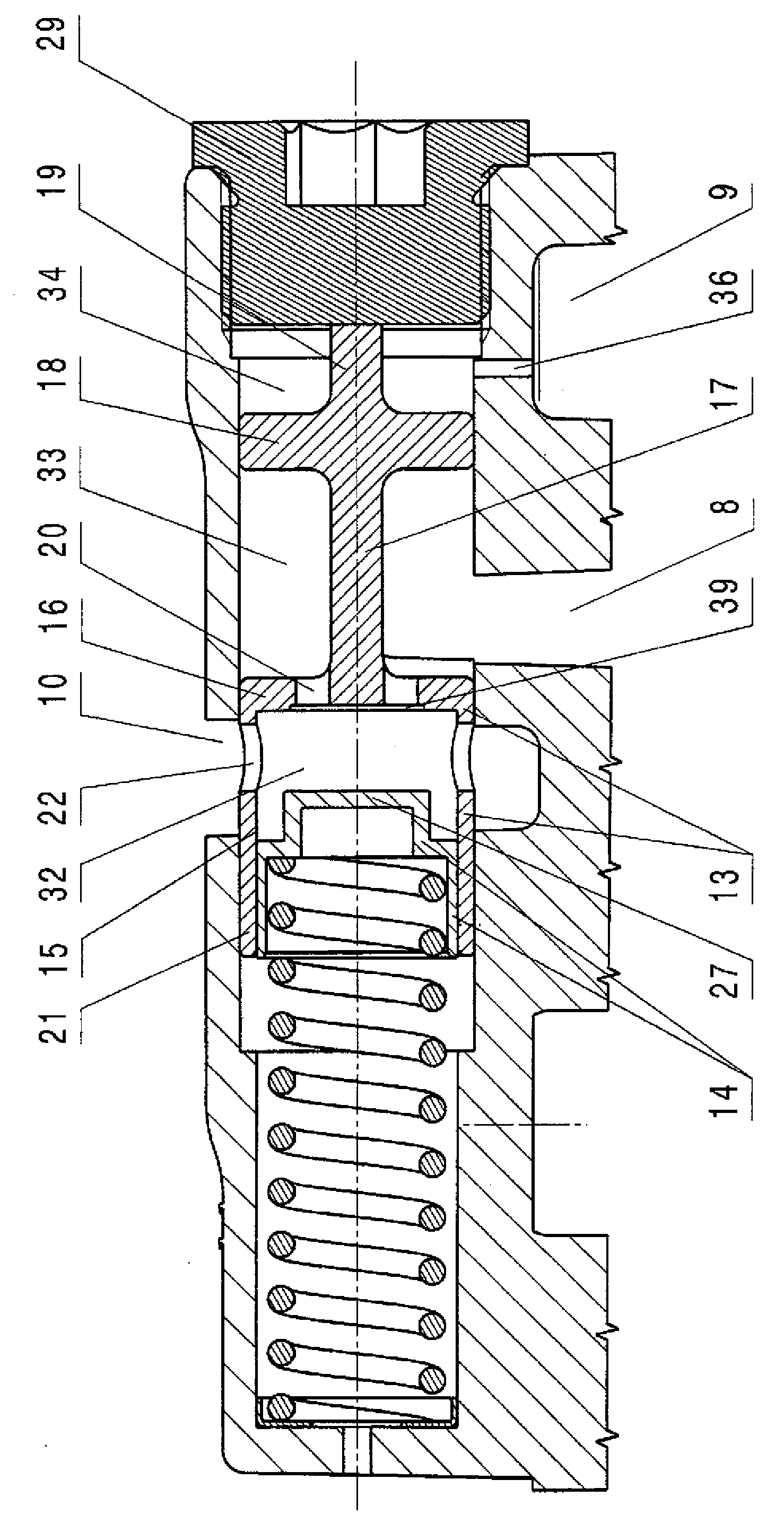

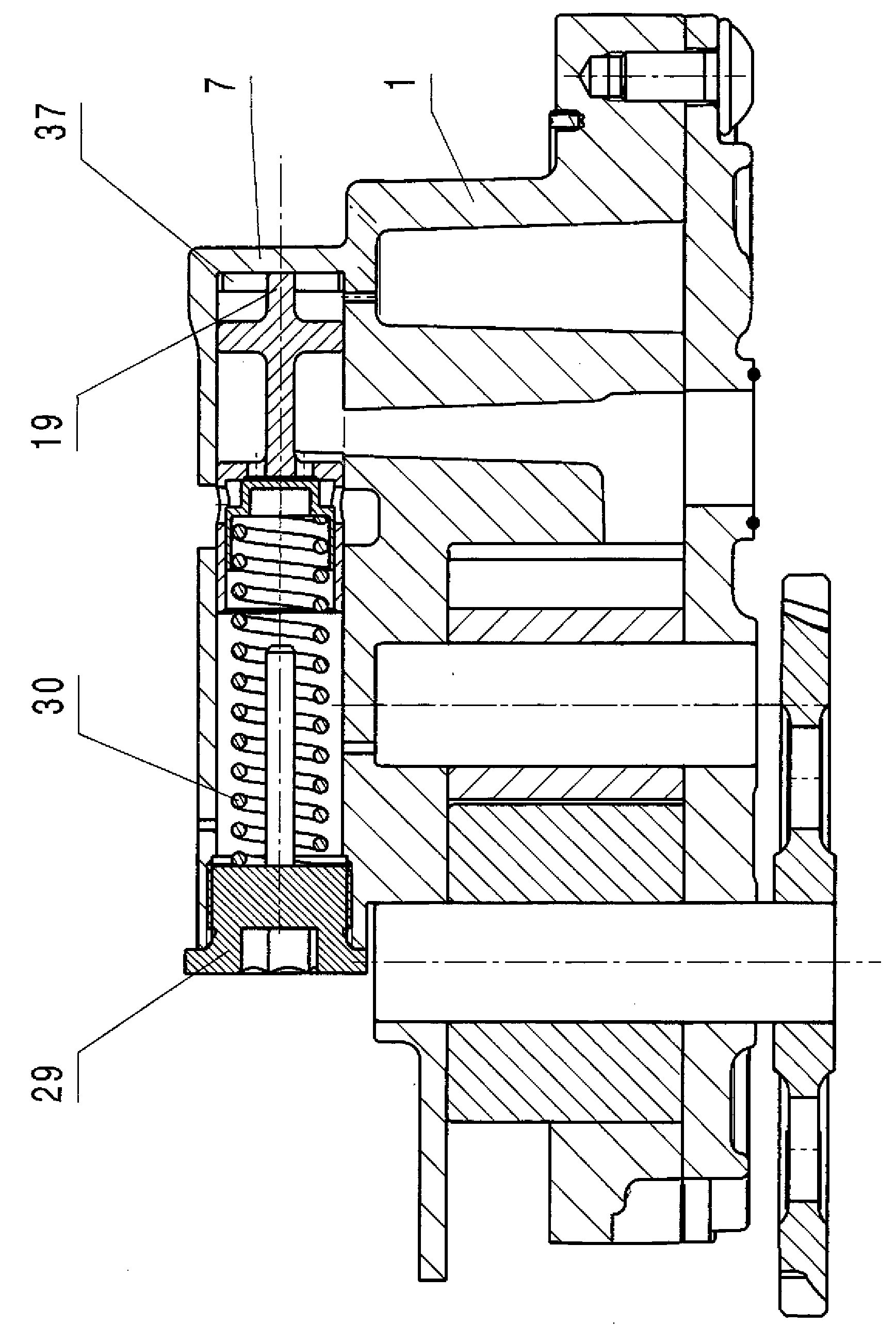

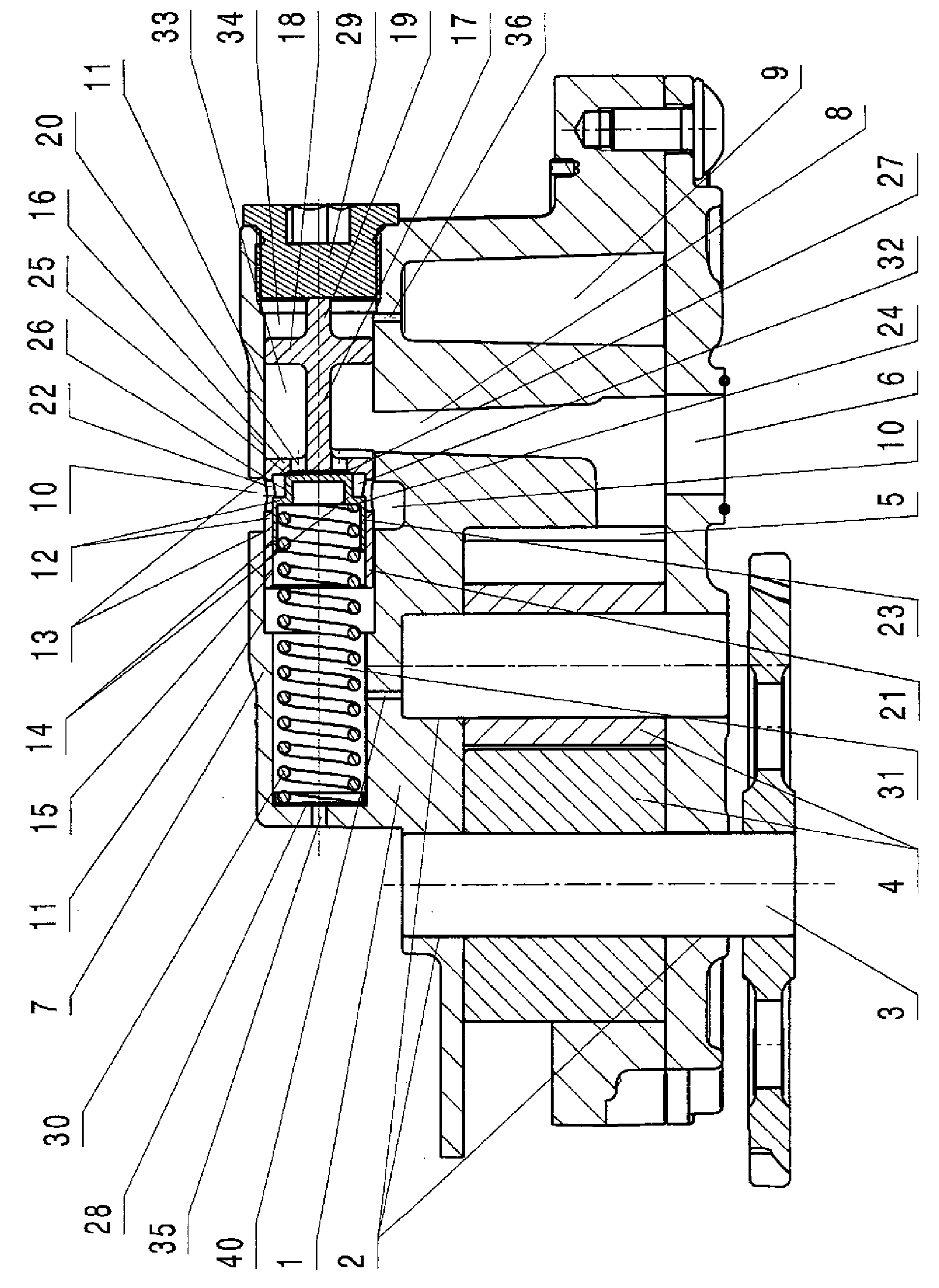

[0025] The pump housing 1 shown in FIG. 1 has: a bearing point 2; a rotating wheel set (Laufradsatz) 4 (of course it can also be Similarly, other oil pump constructions, such as a rotary wheel set of a cycloidal rotor pump), which have pressure waists (Druckniere) 5 arranged in the pressure region of the pump housing 1; Pressure connection channel (Druckanschlusskanal) 6 arranged at the pump housing 1 with a valve seat 7 arranged at the pump housing 1, a pressure channel 8 arranged between the valve seat 7 and the pressure connection channel 6, arranged at Control channel 9 between valve seat 7 and passage and overflow channel 10 arranged between valve seat 7 and oil sump; with piston guide 11 arranged in valve seat 7 in pump housing 1 Double piston 12 with an outer adjusting piston 13, in which an inner piston guide for the inner piston is arranged, wherein a piston rod 17 with at least one working piston 18 is arranged on the adjusting piston, the piston rod 17 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com