Wear debris sensor sensitivity increasing method based on combination of band-pass filtering and correlation operation

A technology of wear sensor and band-pass filter, which is applied in the direction of instruments and analytical materials, and can solve problems such as the inapplicability of simple correlation calculations, the weakening of interference elimination effects, and the robustness of parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

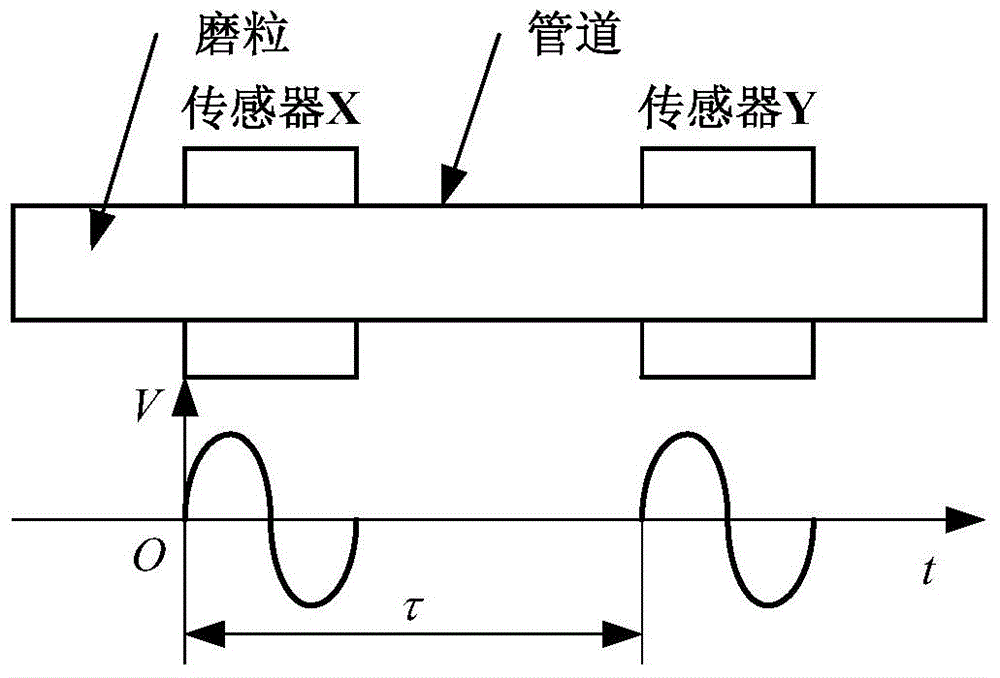

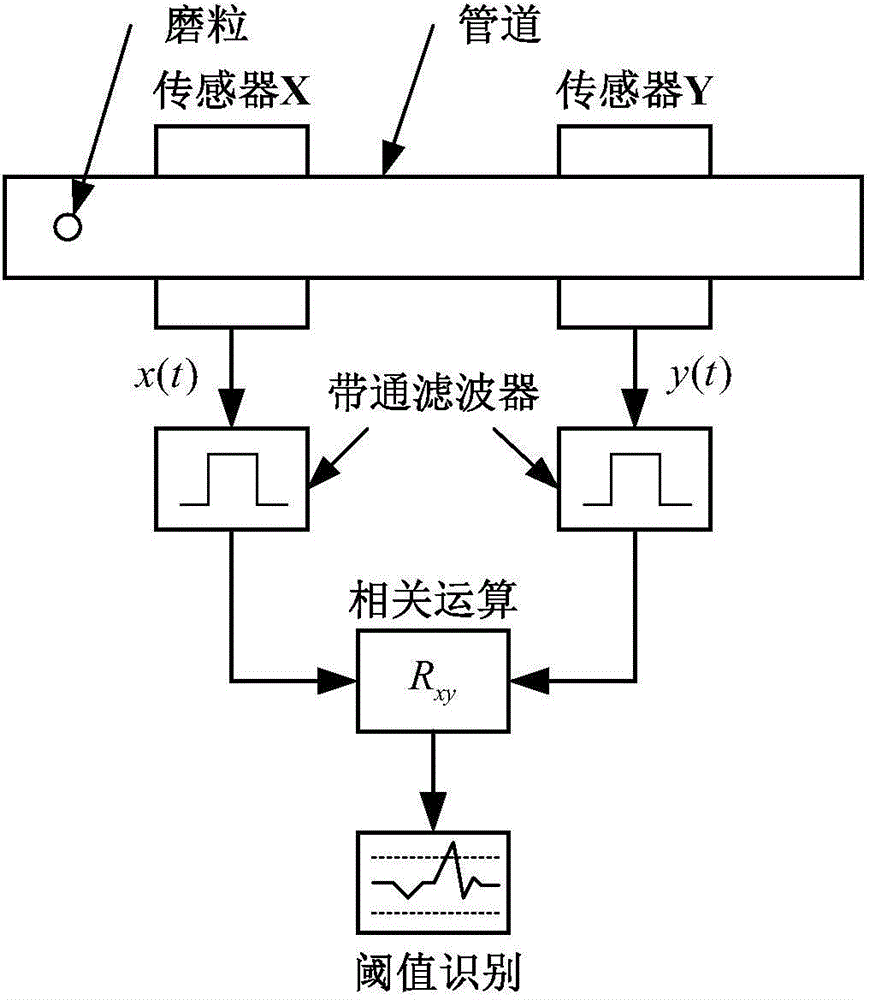

Method used

Image

Examples

Embodiment

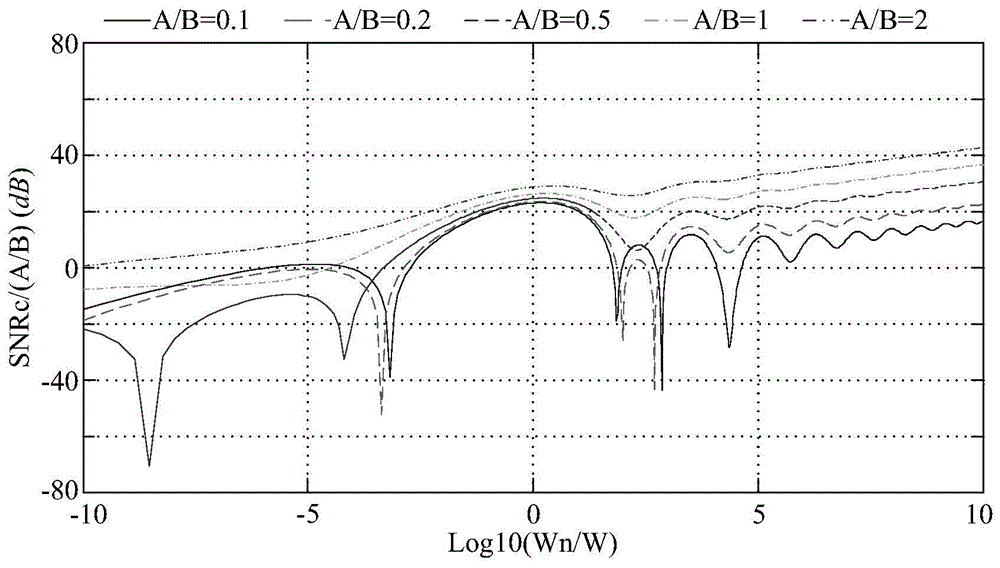

[0102] In order to verify the performance of the band-pass correlation method under actual interference, the output signal of the sensor when no abrasive particles pass and the waveform of the simulated abrasive particle signal are superimposed as the sensor output. Figure 5 is the actual interference waveform and the FFT result. It is obvious that the actual interference is also composed of random noise and interference of specific frequency, and the large amplitude at some frequency in the frequency spectrum is caused by alternating current and vibration. Since the maximum amplitude of the actual interference is 0.02 near the frequency of 100Hz, the amplitude A of the abrasive particle signal is respectively 0.002, 0.005, 0.01, 0.02, and 0.04 for comparison. The results are as follows Figure 6 shown. The results show that when A≥0.01, the threshold method can effectively monitor the wear particles, so the effect of the bandpass correlation method in the actual interferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com