Modular knee prosthesis

A knee joint prosthesis, modular technology, applied in the field of knee joint prosthesis kits, can solve the problems of lateralization, patella dislocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

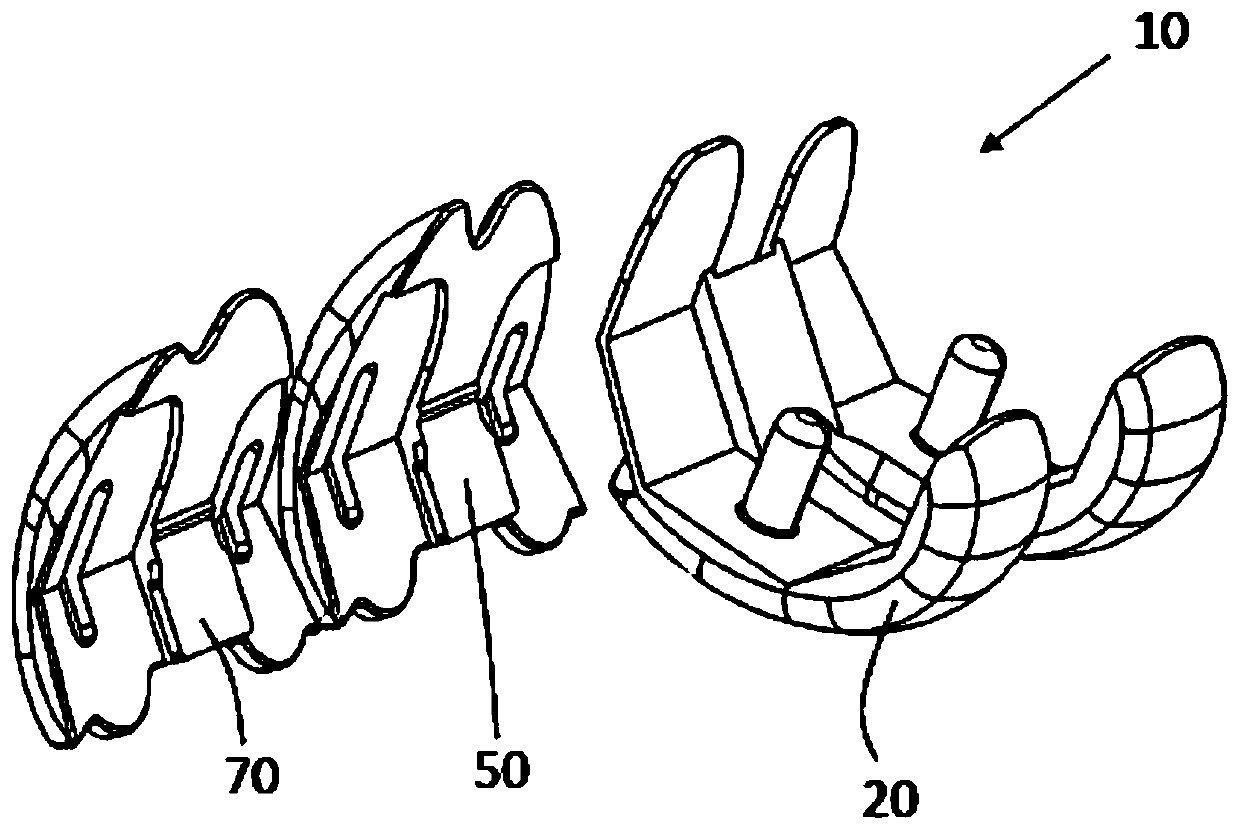

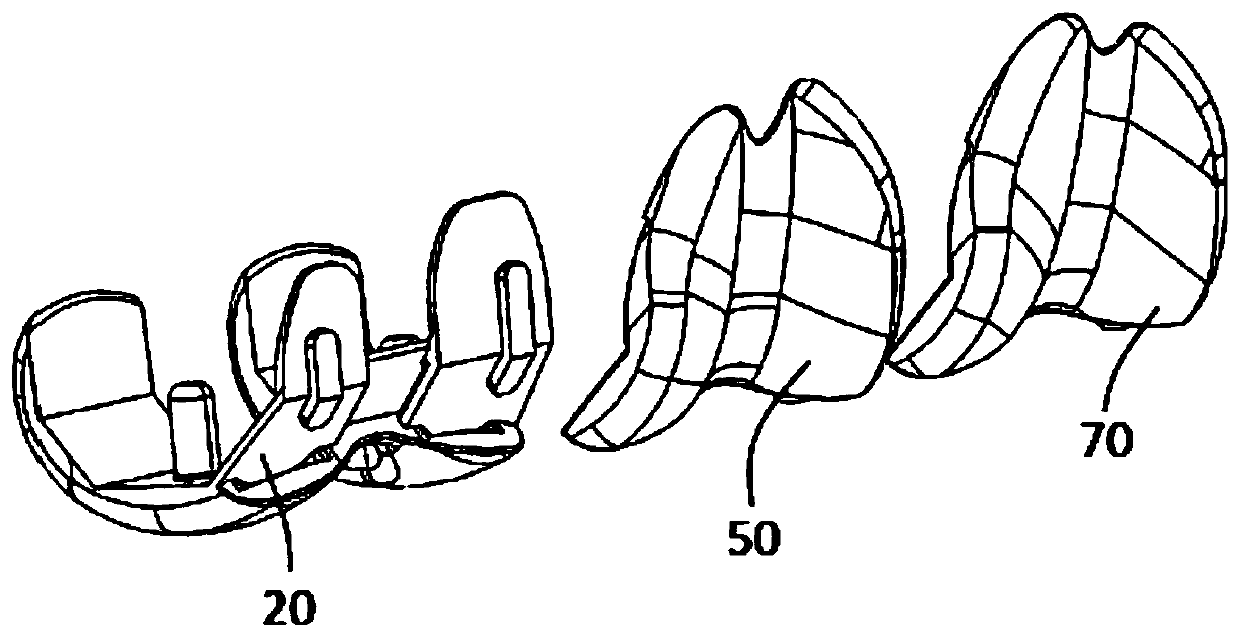

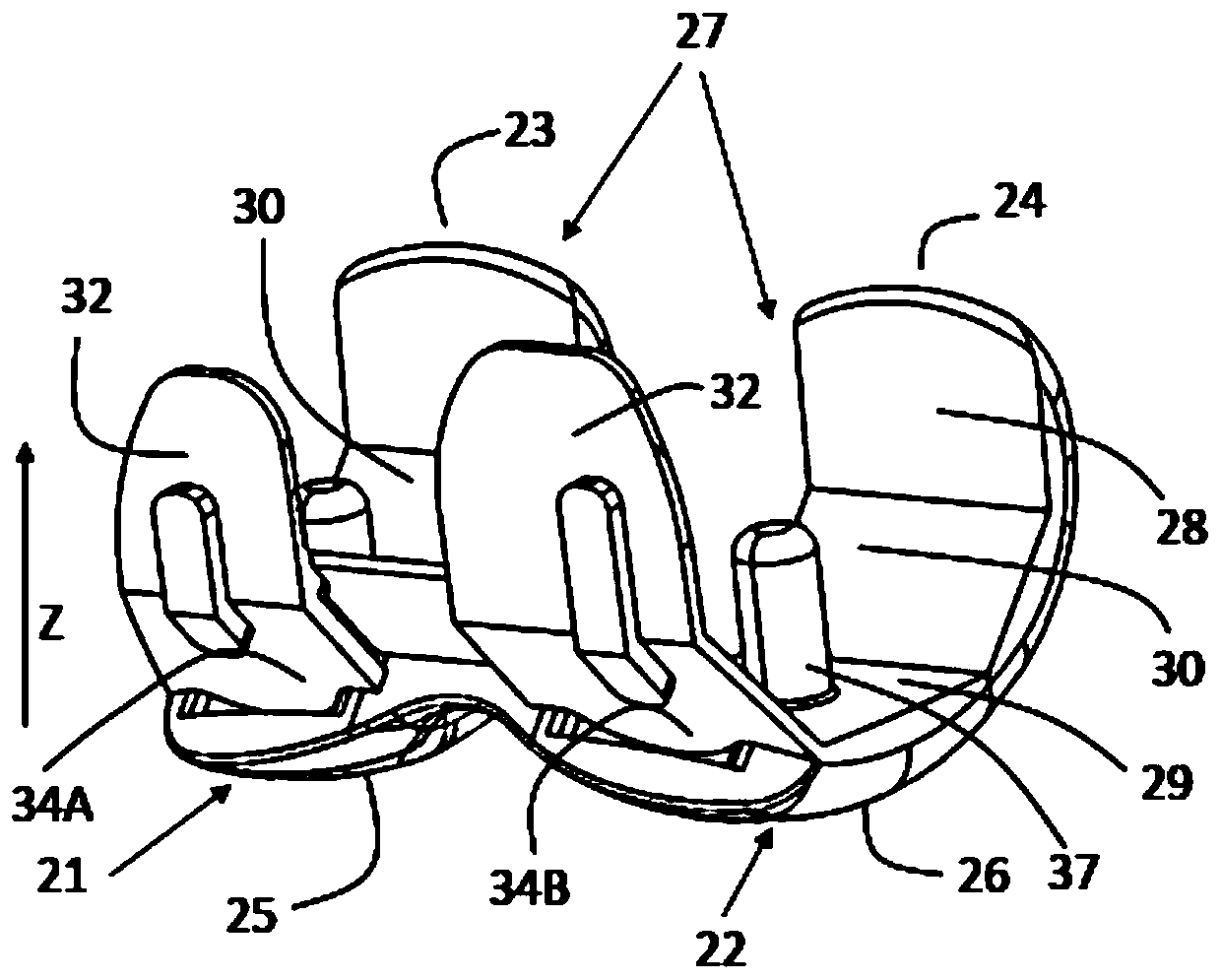

[0023] refer to Figure 1A , shows a modular total knee prosthesis assembly kit 10 for replacing the resected articular surface of the distal femur. Figure 1B Depicted are the bicondylar component 20 and the first 50 and second 70 trochlear component, anatomically shaped for replacement of the patient's right knee joint. A mirror image of the part will represent an example design for the patient's left knee. Figure 1B shown with Figure 1A Same parts, but with different angles. It should be noted that the knee prosthesis assembly kit 10 may include additional bicondylar components 20 and / or trochlear groove components 50; slightly different, which will be explained in more detail later. In this example, the trochlear channel member 50; 70 and the bicondylar member 20 are both unitary members (ie, constructed from a single piece). When assembled together, the bicondylar component 20 and one of the trochlear components 50, 70 form a (modular) femoral component. In this exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com