Prosthetic knee implant systems and methods with linked tibial rotation

A tibial, bearing surface technology for orthopedic devices that addresses issues such as poor rotation of the tibial component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

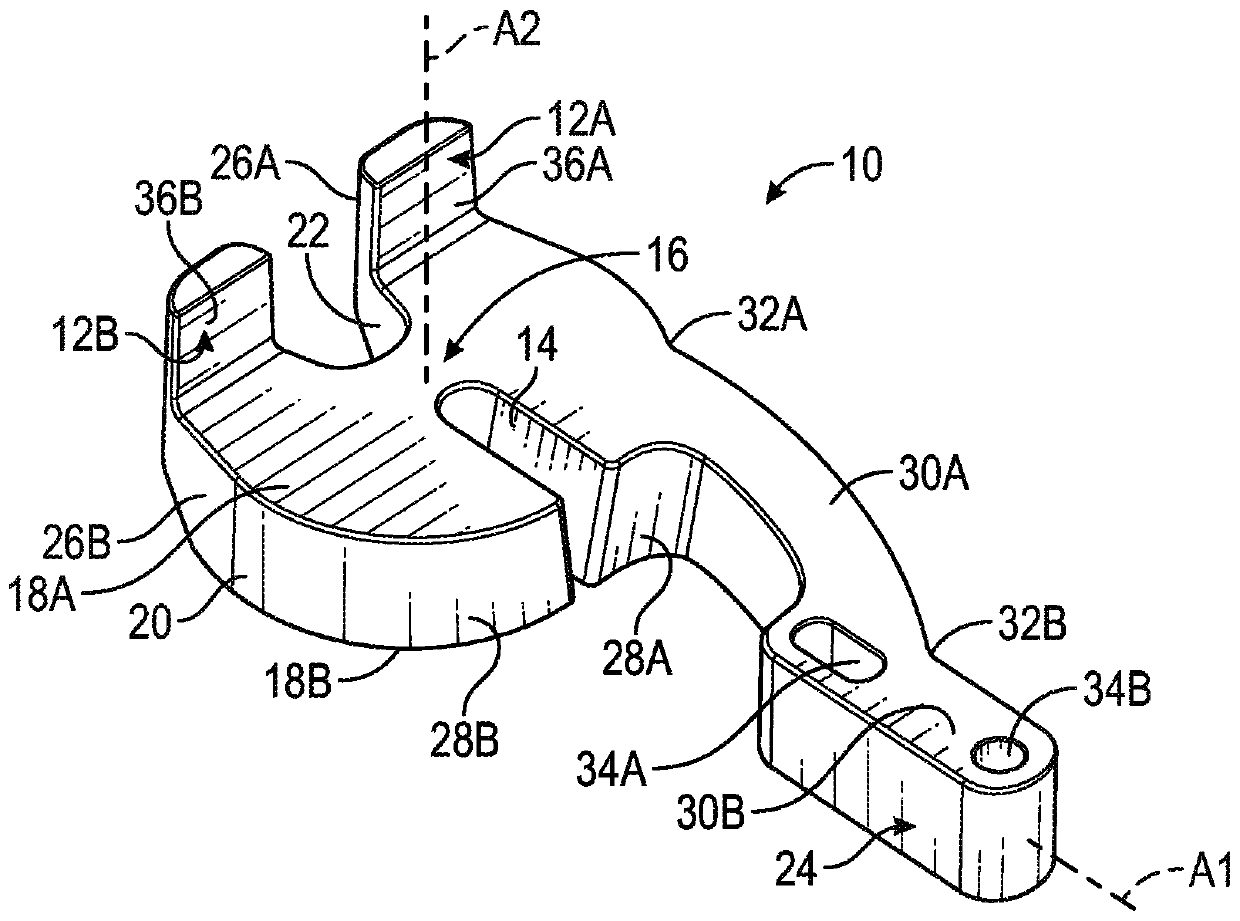

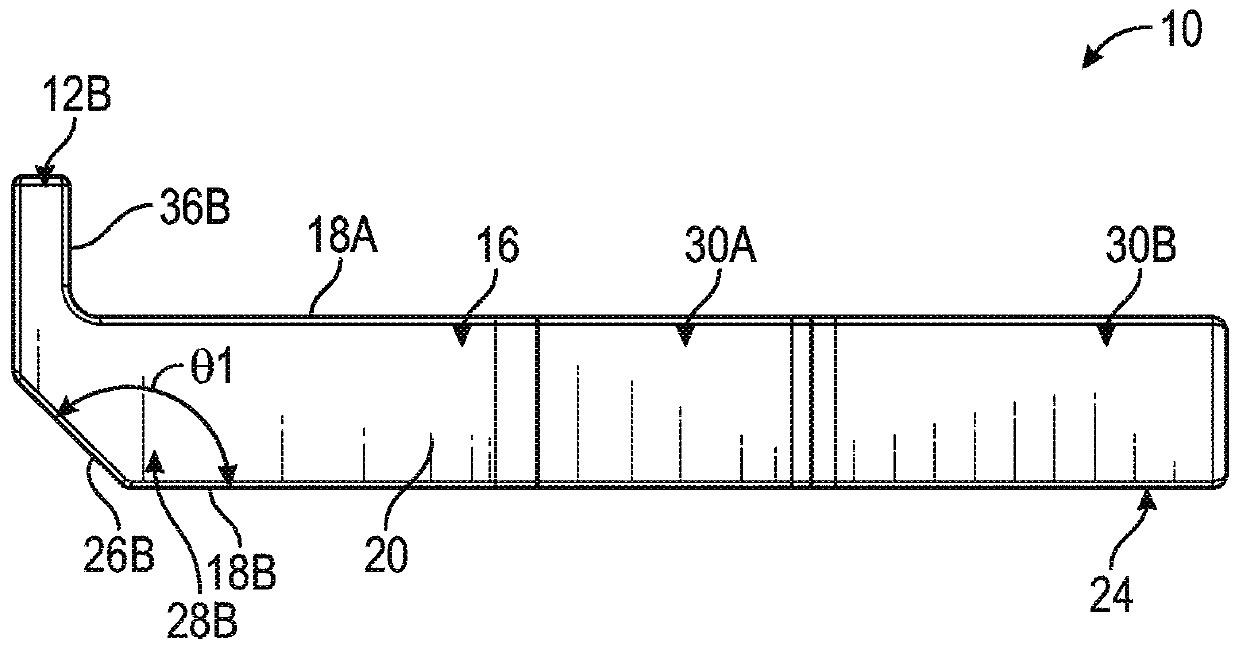

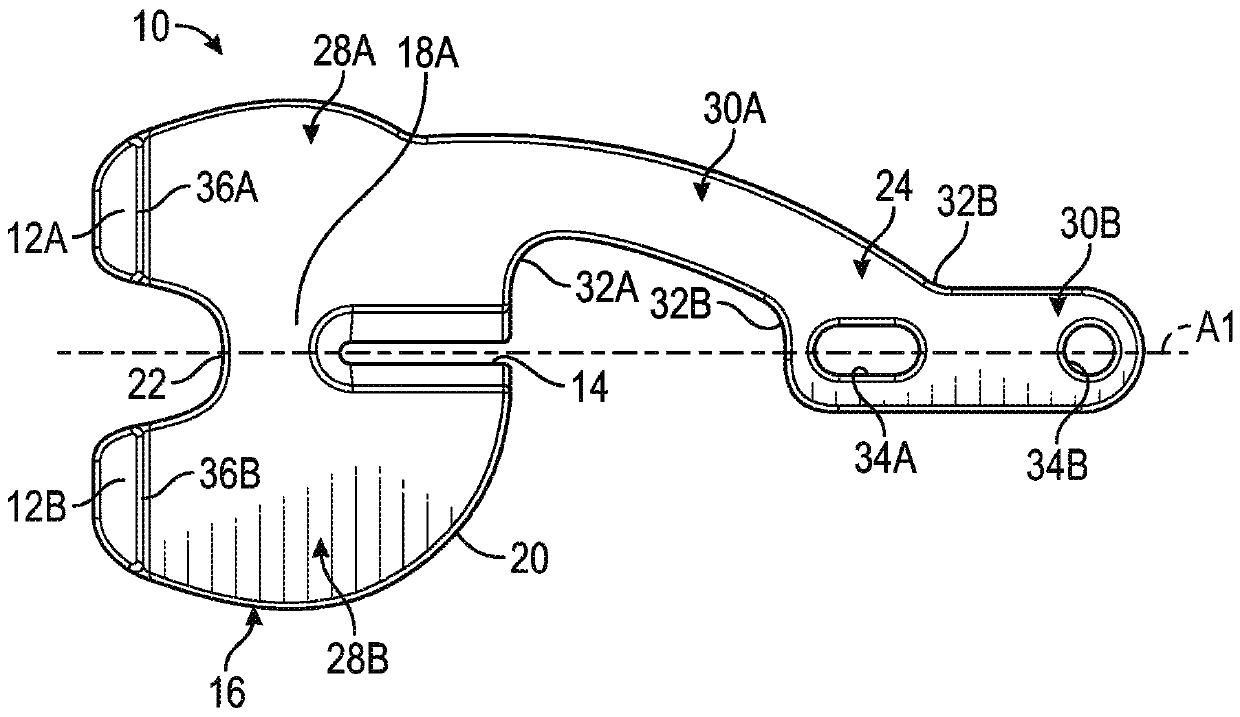

[0045] figure 1 is a perspective view of tibial spacer plate 10 with alignment feet 12A and 12B and index slot 14 disposed in spacer block 16 . figure 2 yes figure 1 A side view of tibial spacer 10, showing the angle of alignment feet 12A and 12B relative to bearing surface 18A. image 3 yes figure 1 A top view of the tibial spacer of , showing the position of the indicator groove 14. Discuss at the same time Figure 1 to Figure 3 .

[0046] The spacer block 16 may include a first bearing surface 18A, a second bearing surface 18B, an edge perimeter surface 20 , a notch 22 and a handle 24 . Edge perimeter surface 20 may include chamfers 26A and 26B opposite alignment feet 12A and 12B, respectively. The notch 22 and the index groove 14 may extend into the spacer block 16 to form a first condyle portion 28A and a second condyle portion 28B. The handle 24 may extend from the edge peripheral surface 20 of the spacer block 16 and may include a first segment 30A and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com