Patents

Literature

104results about How to "Reduced risk of loosening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

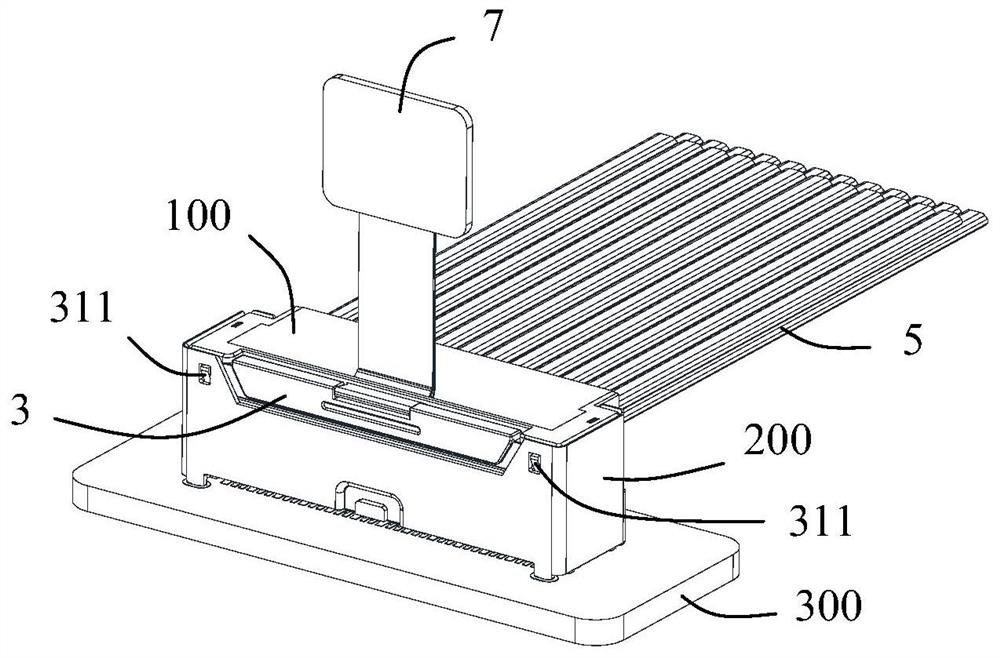

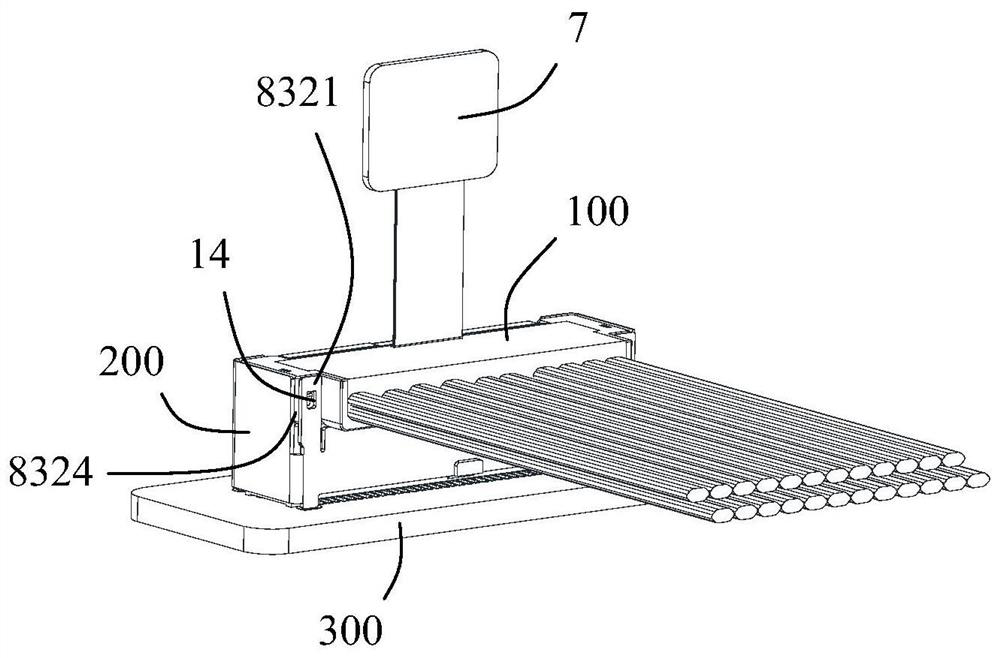

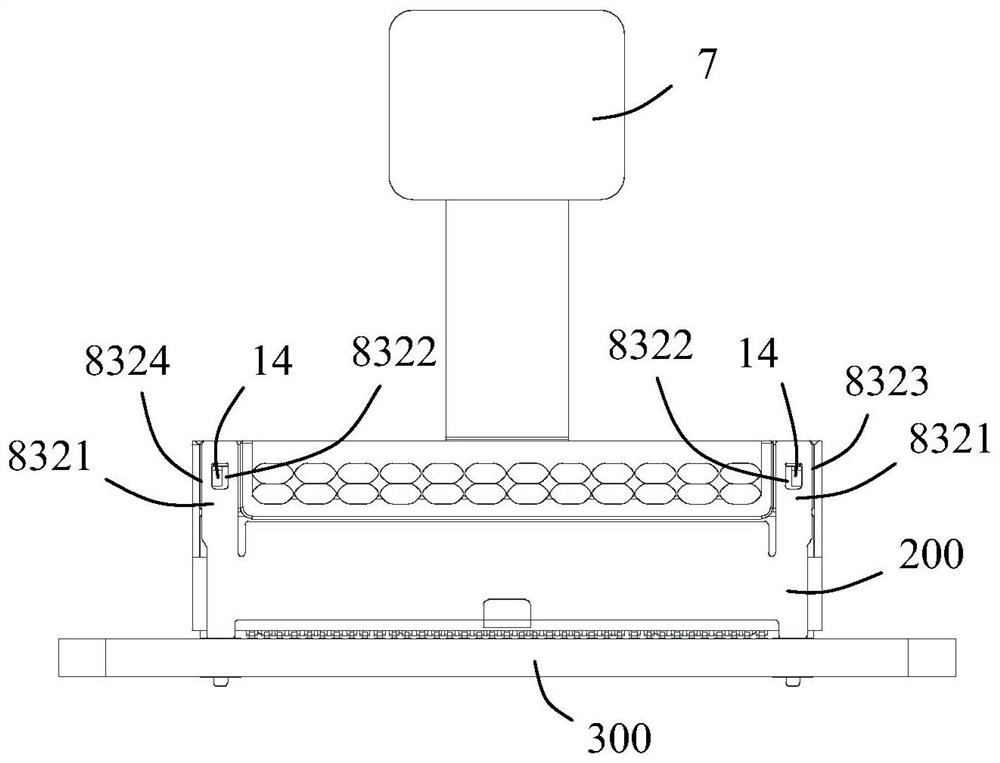

Double-loop-line intersected belt sorting machine, intersected belt sorting system and sorting method thereof

PendingCN109335538AReduce vacancy rateIncrease the number ofPackagingConveyor partsEngineeringMechanical engineering

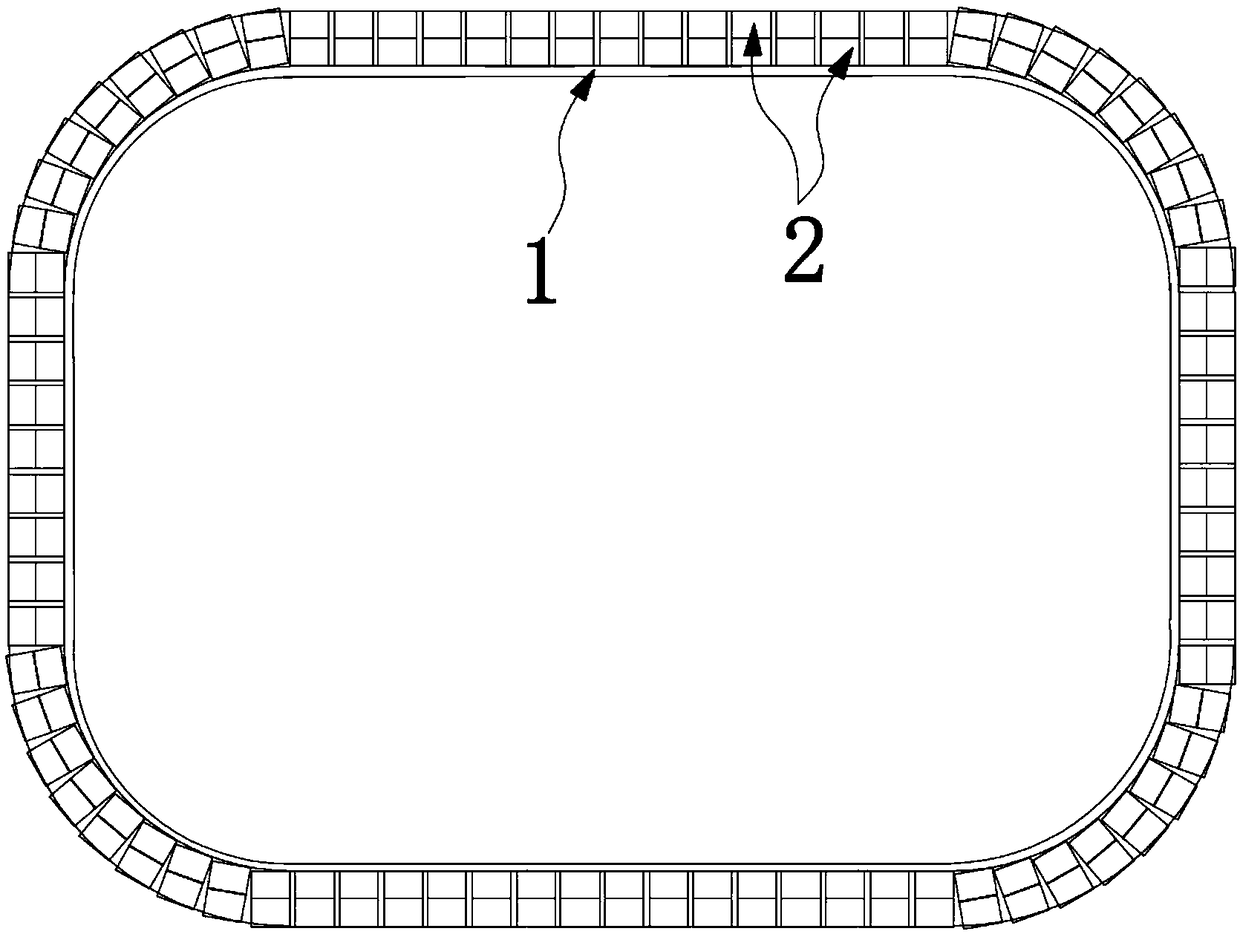

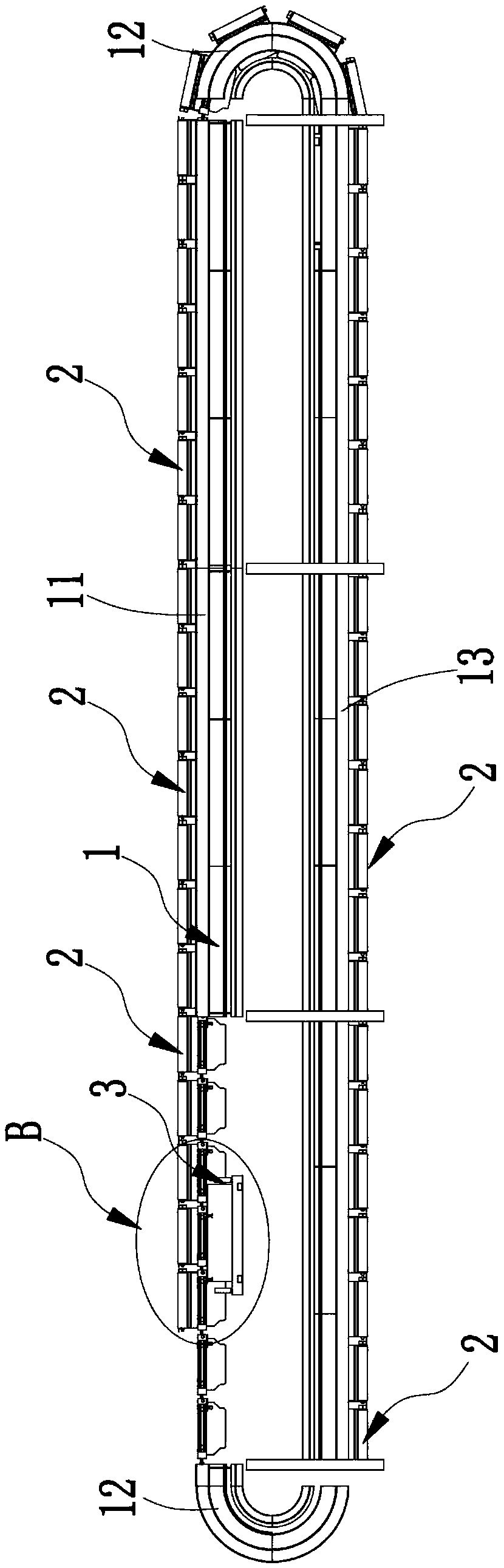

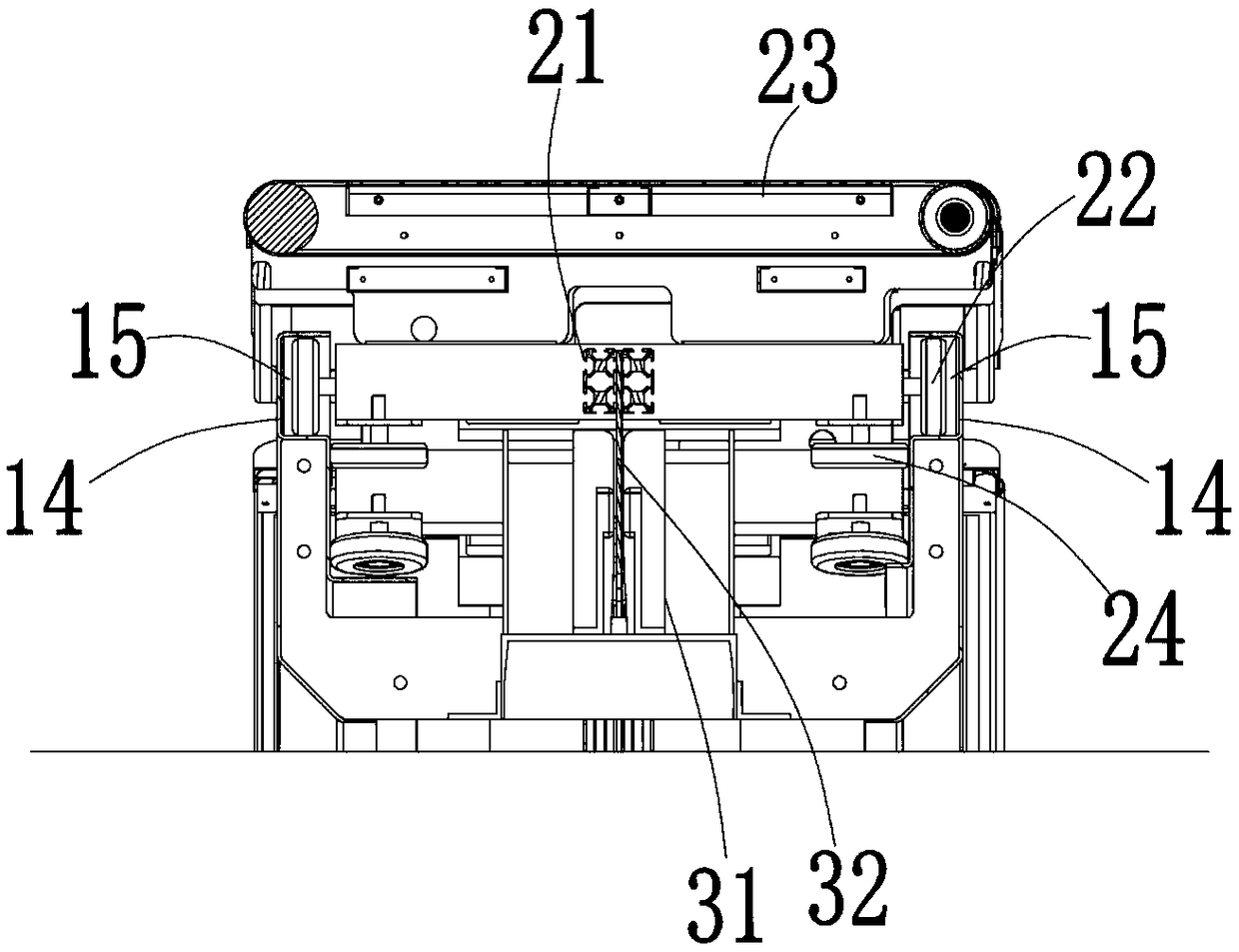

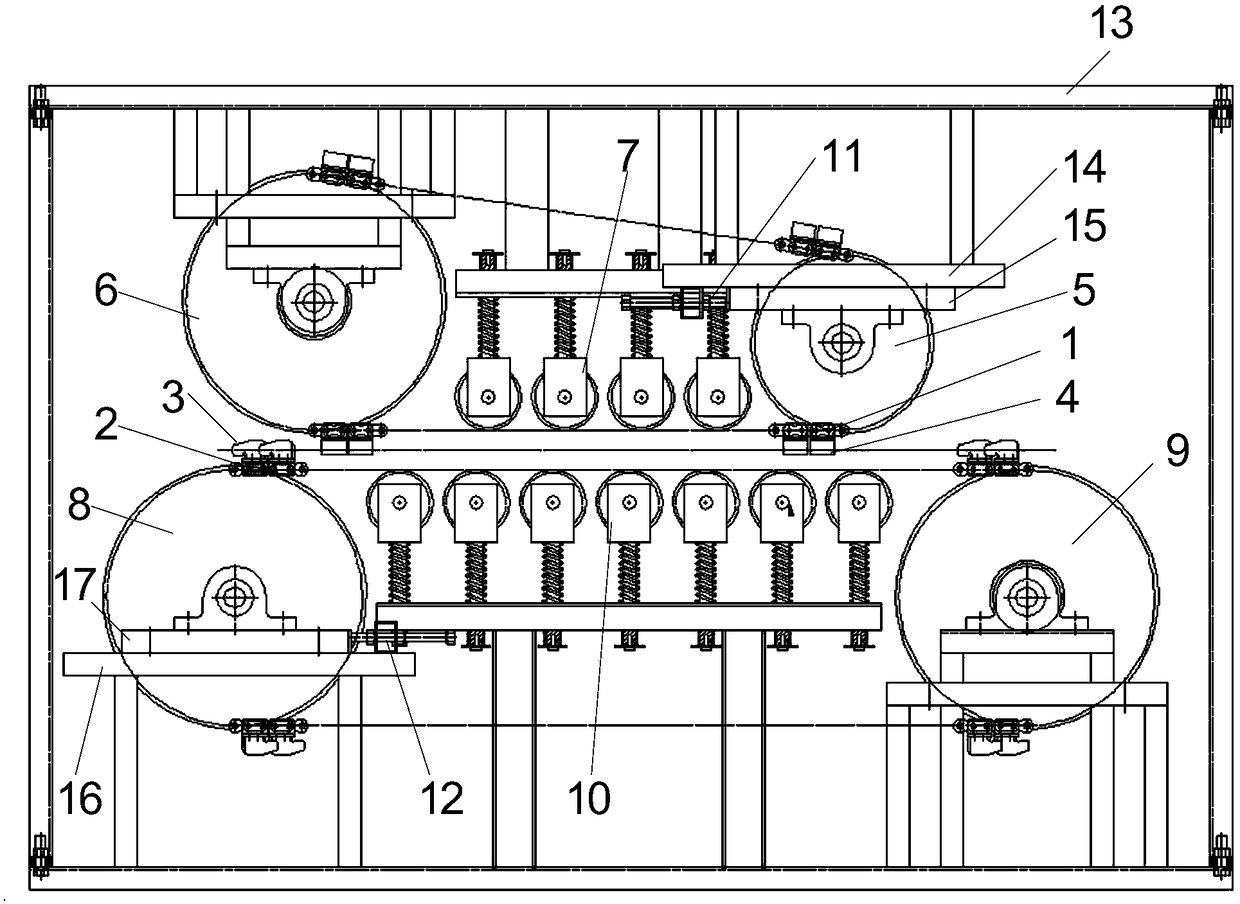

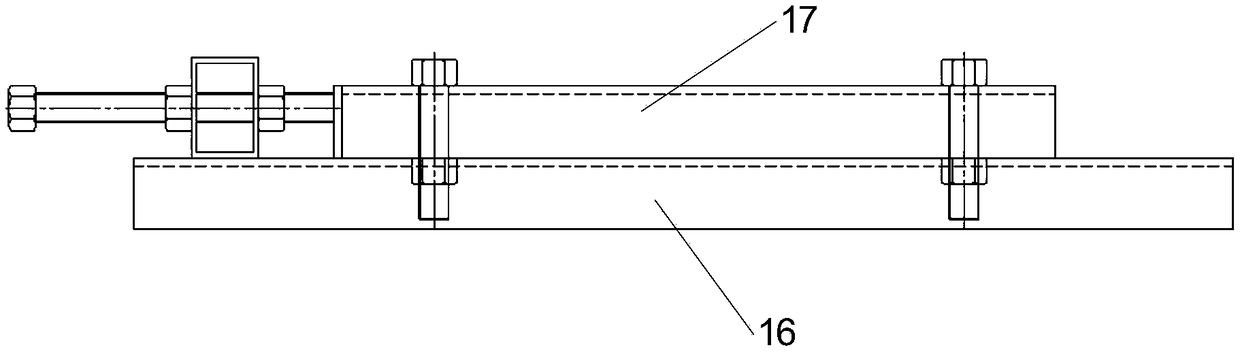

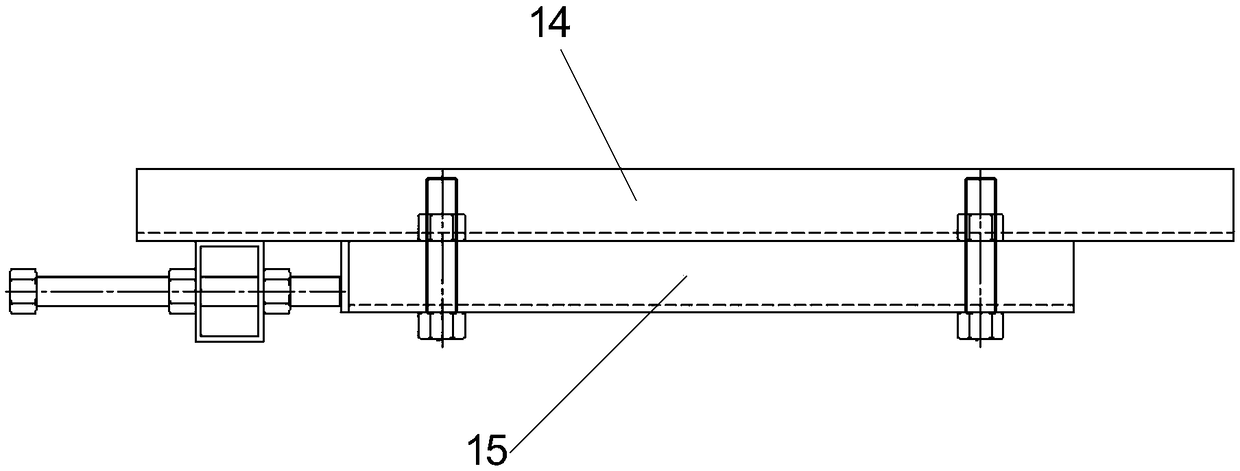

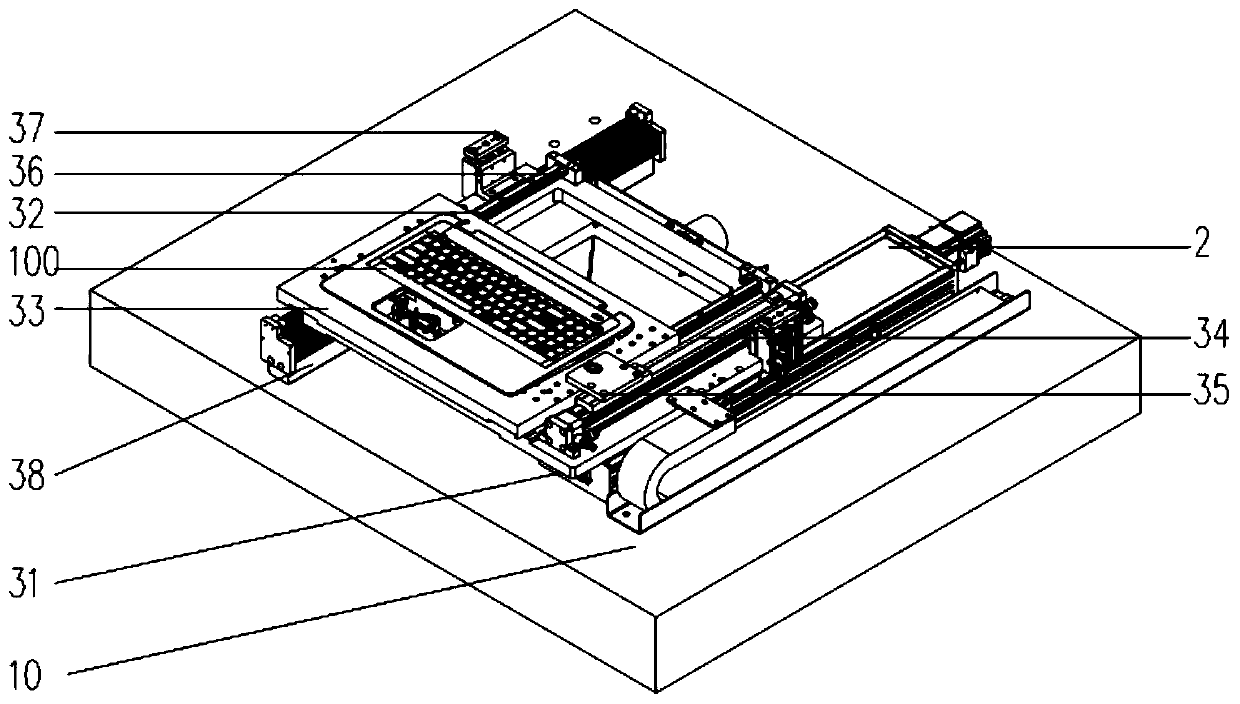

The invention discloses a double-loop-line intersected belt sorting machine, an intersected belt sorting system and a sorting method thereof. The double-loop-line intersected belt sorting machine comprises at least one annular rail, two sets of intersected belt cars for forming two conveying loop lines circularly rotated on the annular rails side by side, and a power device for driving the two sets of intersected belt cars to move along the annular rails. The double-loop-line intersected belt sorting machine is delicate in design and simple in structure; as two sets of cars are used in one annular rail, the number of the intersected belt cars is increased by using internal space of the loop lines under the precondition of not increasing the floor area to multiply the sorting capacity, theuse efficiency of the sorting machine is improved, and the equipment cost is reduced; and meanwhile, parcels can be transferred between two conveying annular intersected belt cars, so that the idlingrate of the cars can be reduced, meanwhile, the parcel loading flexibility is improved, and the arrangement requirements and the occupied space of a particle loading line are reduced.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

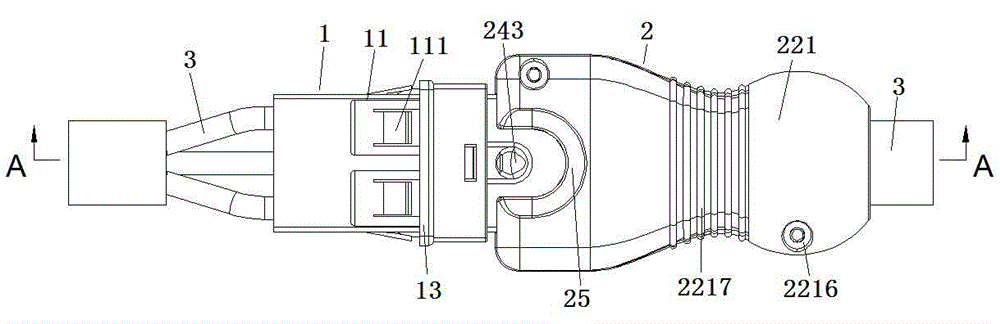

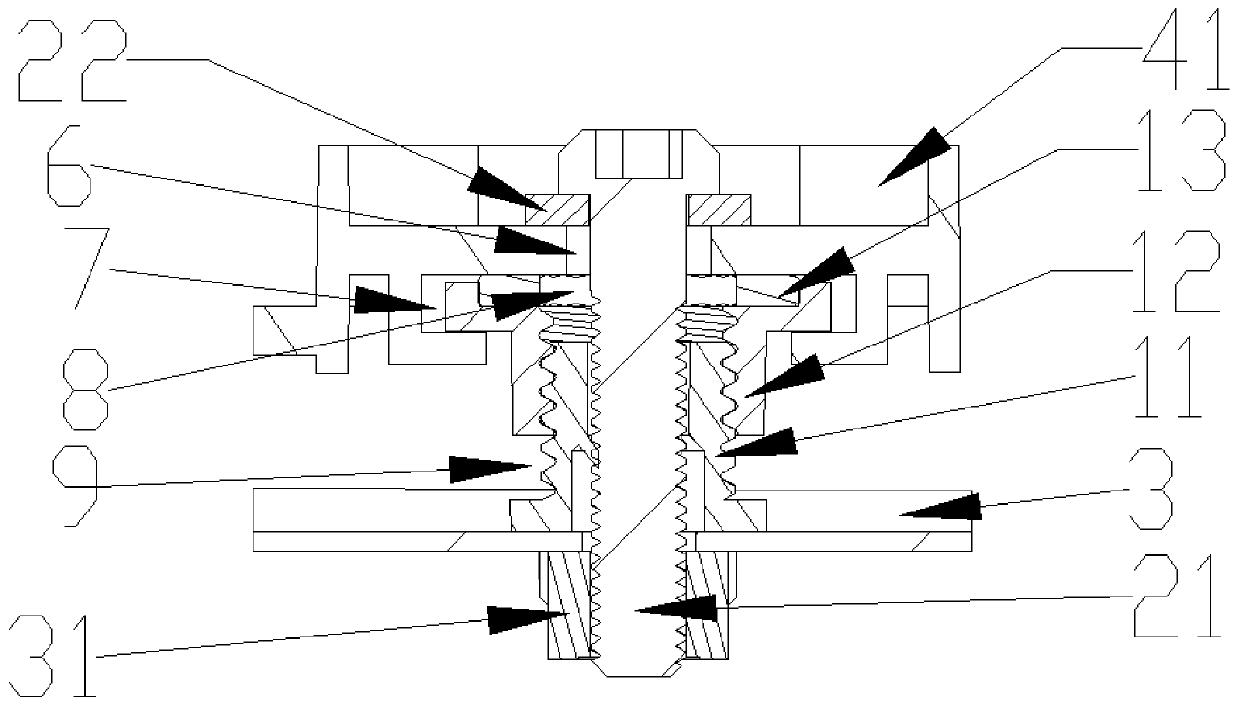

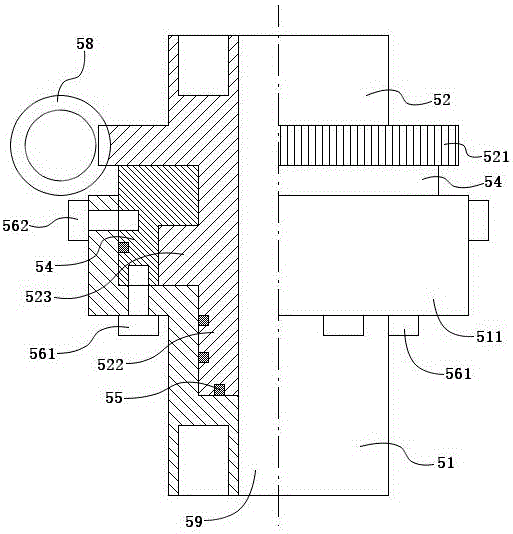

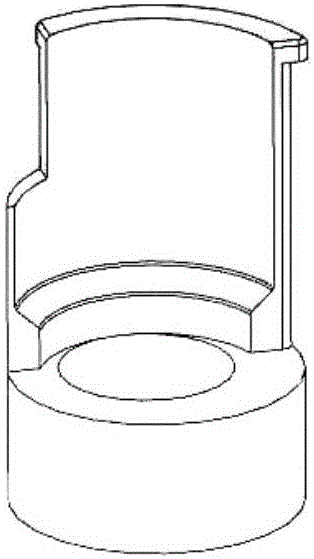

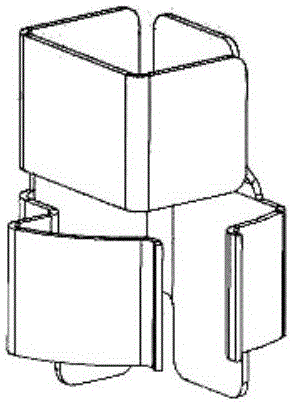

High-current input connector applied to PDU

ActiveCN104682106AMeet narrow width design needsReduced risk of looseningIncorrect coupling preventionCouplings bases/casesEngineeringHigh current

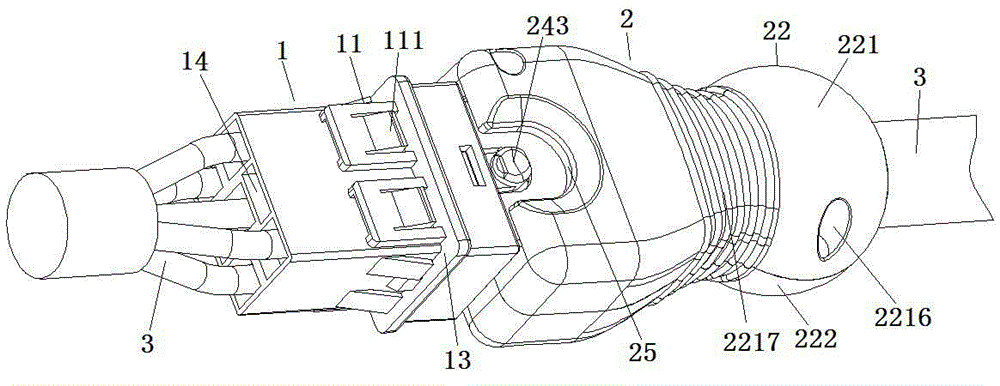

The invention relates to a high-current input connector applied to a PDU. The high-current input connector comprises a socket and a plug, wherein the socket is fixed on a PDU mounting groove through peripheral elastic elements; a plurality of plug-ins A with internal conductive plug-in sheets are arranged at the head of the socket; the conductive plug-in sheets are connected with cables penetrating through the interior of a mounting groove in the tail of the socket; the plug comprises a substrate; a plurality of plug-ins B with internal conductive plug-in sheets are arranged at the head of the substrate, and cables connected with the conductive plug-in sheets are arranged at the tail of the substrate; the substrate is wrapped with a handle which is fixedly connected with the substrate through a positioning device; the end, in contact with the cable, of the handle has an inverted tooth structure; the socket is fixedly connected with the plug through an elastic hasp. The high-current input connector applied to the PDU can be used for the high-current connection of the PDU, and is small in size, low in loosening rate, simple in structure, convenient to mount and high in efficiency.

Owner:FUZHOU LIUFANG MECHANICAL & ELECTRICAL

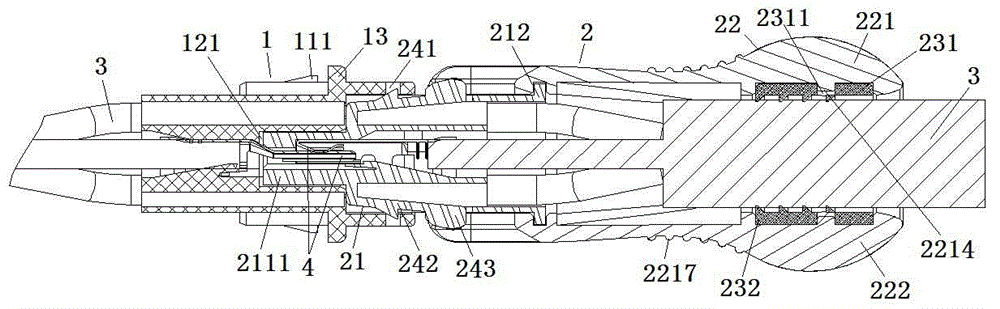

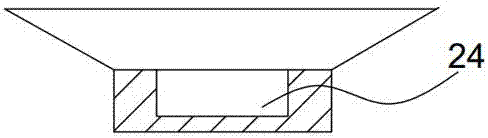

Mounting structure for hidden handle and mounting method thereof

PendingCN110306889AEasy to operatePromote engineering applicationVehicle locksArchitectural engineeringGasket

The invention provides a mounting structure for a hidden handle. The mounting structure comprises tolerance adjusters, bolt assemblies, an inner metal plate and the hidden handle, wherein each tolerance adjuster comprises a locking piece and a thread set sleeve piece, each thread set sleeve piece comprises a positioning nut and an elastic piece adjusting stud, each bolt assembly comprises a fastening bolt and a fixing gasket, handle base positioning structures are arranged on the hidden handle, a first open groove and bolt mounting via holes are formed in the inner metal plate, and the bottomend surface of the inner metal plate is provided with fixing nuts with the same hole centers as the bolt mounting via holes in a welding mode. The invention further provides a mounting method of the mounting structure for the hidden handle. According to the mounting structure for the hidden handle and the mounting method thereof, three-point positioning and lateral sliding-in mounting modes are adopted, so that the assembly efficiency is improved, and the stability and firmness are enhanced; and moreover, full-automatic three-directional tolerance adjustment and zero external stress mounting are achieved, so that the mounting process is smoother, and the cost is greatly reduced.

Owner:SHANGHAI JIAMU AUTO PARTS CO LTD

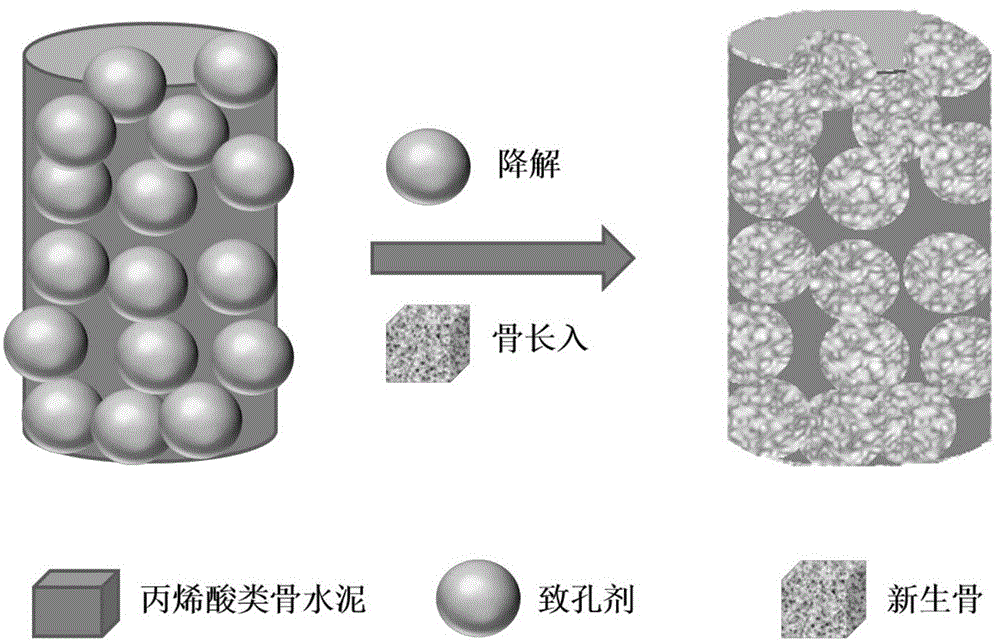

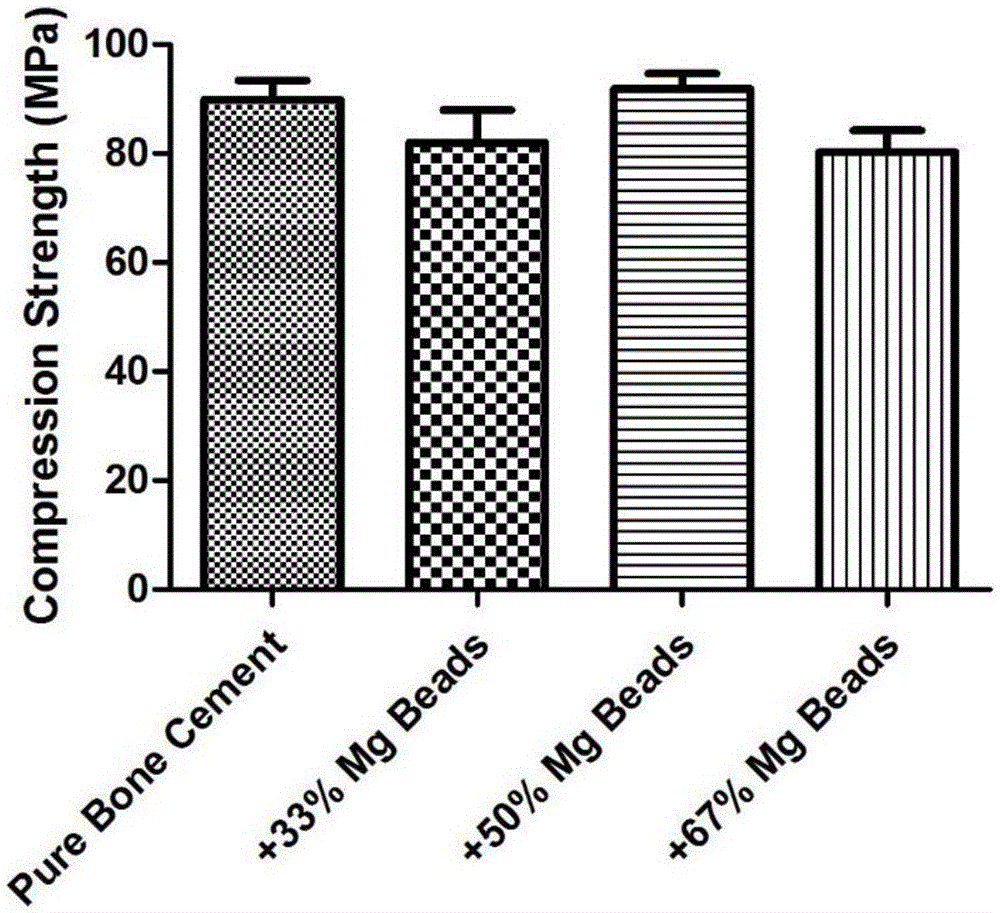

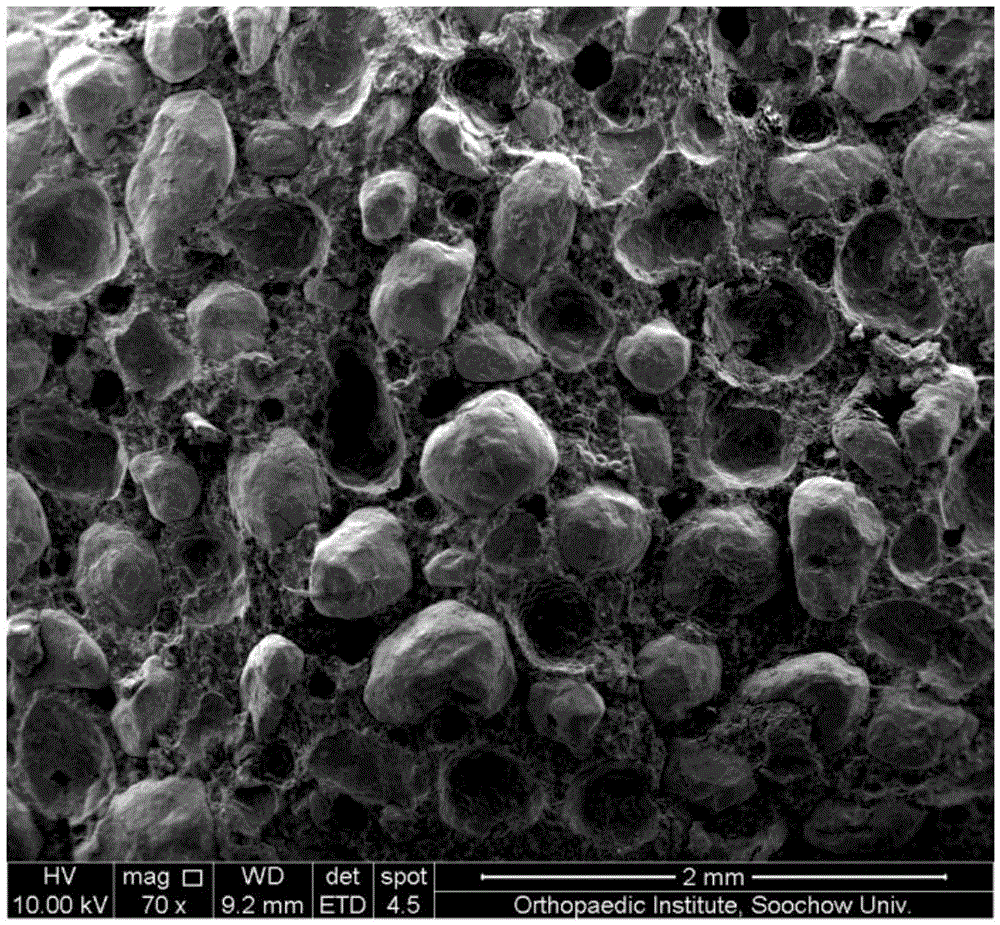

Acrylic compound bone cement with partial degradation function and preparation method of acrylic compound bone cement with partial degradation function

ActiveCN105288741AReduced risk of looseningStable and firm interface bindingProsthesisMicrosphereMicrometer

The invention provides acrylic compound bone cement with a partial degradation function and a preparation method of the acrylic compound bone cement with the partial degradation function. The acrylic compound bone cement is composed of acrylic polymer powder, contrast medium doped solid powder, acrylic monomers and a pore-forming agent with a degradation function, and the pore-forming agent is made from degradable microspheres or particles 100-1500 micrometers in diameter. Compared with acrylic bone cement in the prior art, the acrylic compound bone cement has the advantages that partial degradation is realized, voids generated in degradation of the pore-forming agents enable growth of new bones, the new bones and the undegraded bone cement are engaged mutually to form a steady interfacial bonding function, and accordingly the risk of looseness of the bone cement can be remarkably reduced. In addition, the modulus of compression of the acrylic compound bone cement is low and closer to that of autogenous bone, and the risk of degeneration or fracture of adjacent segments can be effectively reduced.

Owner:SUZHOU UNIV

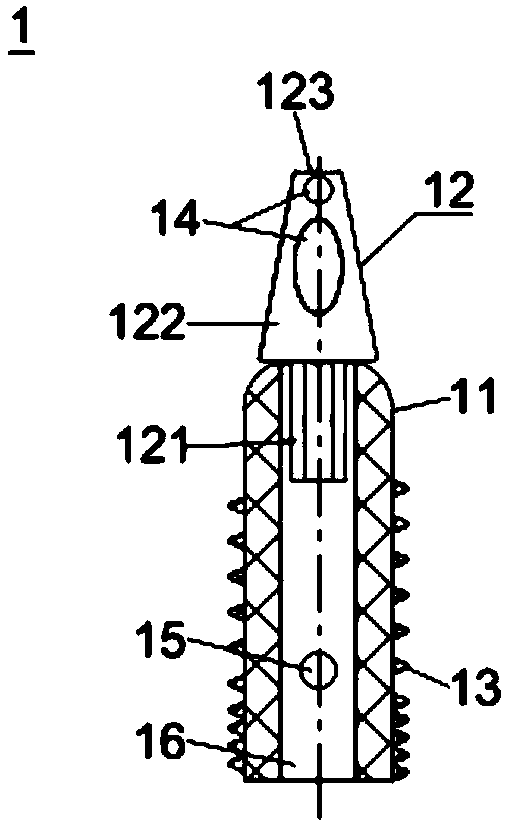

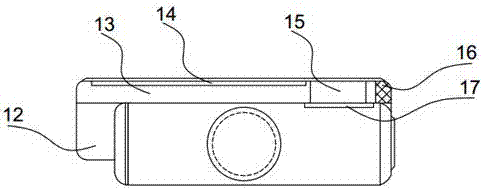

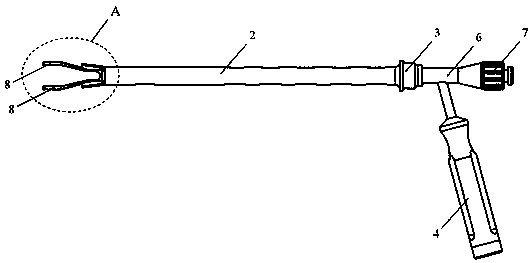

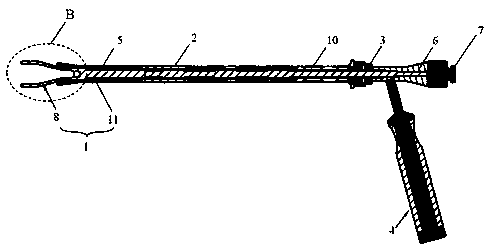

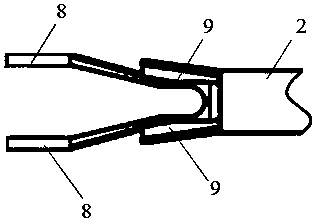

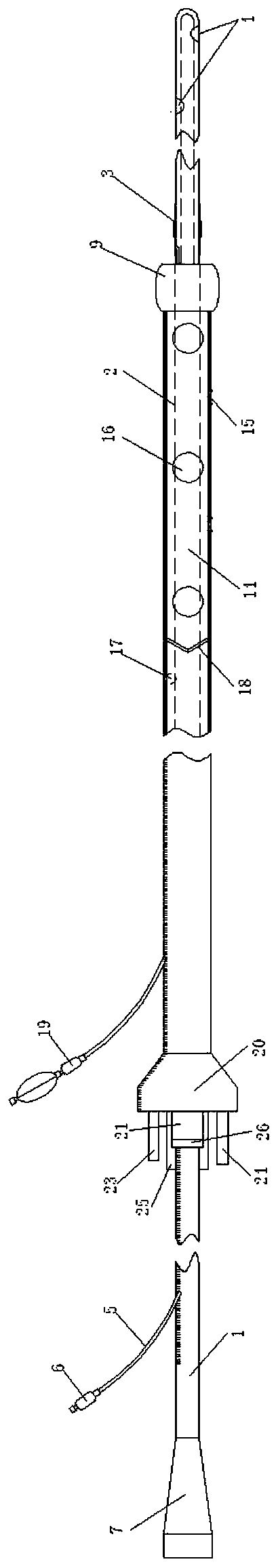

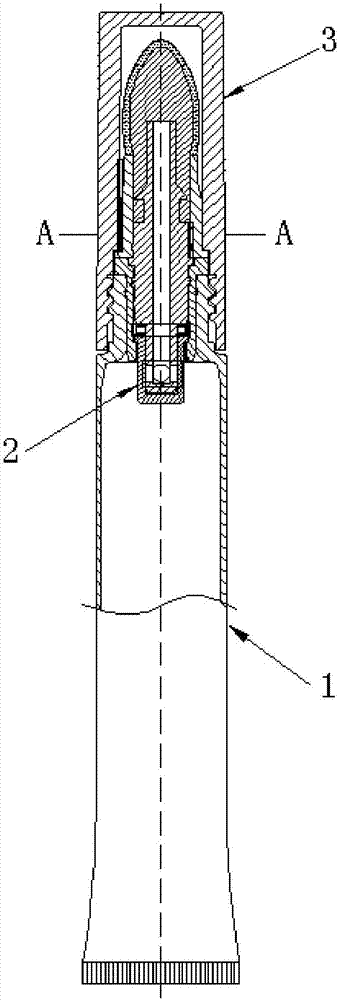

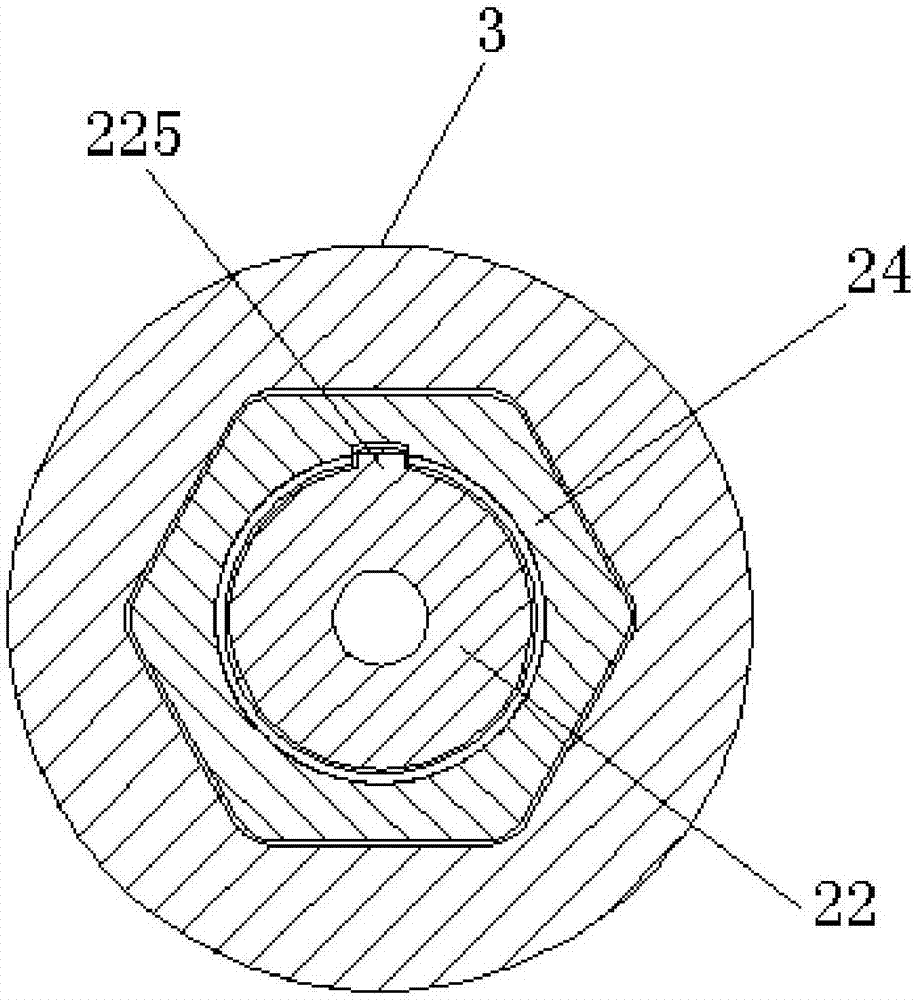

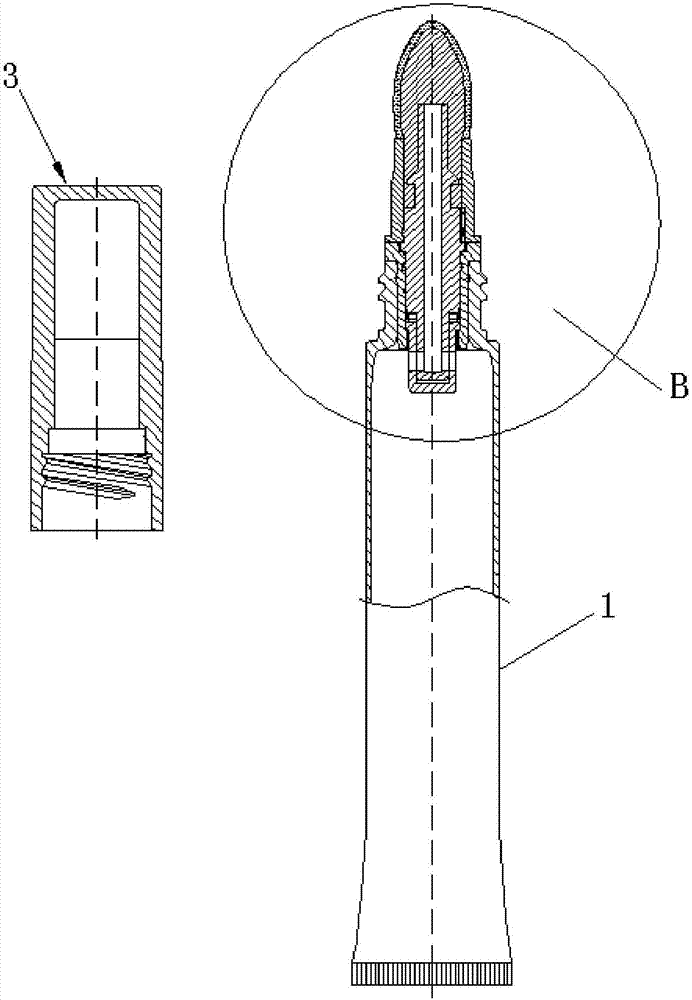

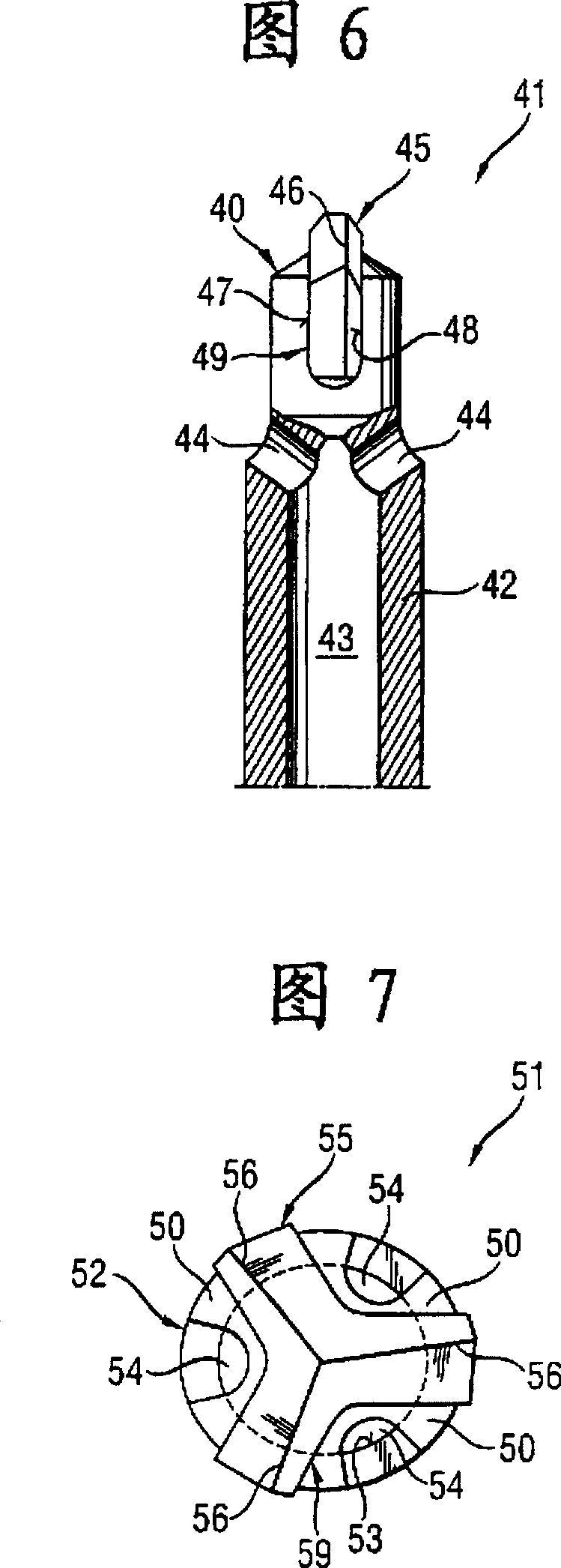

Knot-free anchor and implantation device thereof

InactiveCN109223076AAvoid axial misalignmentImproving Implantation EfficiencySuture equipmentsImplantable rodMedical device

The invention relates to the field of medical devices, and discloses a knot-free anchor and an implantation device thereof. The knot-free anchor comprises an anchor body and a threading portion located at a top end position of the anchor body, a first external thread is formed on an outer peripheral wall of the anchor body, and a threading hole is formed on the threading portion. The structure ofthe implantation device comprises: a rotary handle including an implantation rod for connecting with a knot-free anchor and an implantation handle coaxially connected with the implantation rod; And asupport handle including a support sleeve and a grip handle coaxially connected to the support sleeve. The knot-free anchor of the invention can make the fixation effect of the suture better, so thatthe knot-free anchor can more stably and effectively fix the soft tissue on the bone, thereby promoting the rapid repair and reconstruction of the soft tissue. The knot-free anchor of the invention can make the fixation effect of the suture better, so that the knot-free anchor can more stably and effectively fix the soft tissue on the bone, thereby promoting the rapid repair and reconstruction ofthe soft tissue.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Shakeproof camera with high reliability

InactiveCN107222667AImprove stabilityImprove reliabilityTelevision system detailsColor television detailsExtreme weatherEngineering

The invention provides a shakeproof camera with high reliability. The shakeproof camera comprises a fixed base and a camera connected with the fixed base, wherein a threaded hole is formed in the surface of the fixed base, a shakeproof cushion is connected with the upper end of the fixed based, a rotary seat is connected with the lower end of the fixed base, a connection rod is connected with the lower end of the rotary seat, the connection rod is connected with a reinforcement connection rod via an externally embedded lantern ring, and the reinforcement connection rod is connected with the camera via a rotating shaft. The camera provided by the invention is highly shakeproof and less influenced by the outside, ensures shooting effectiveness, and the camera is firm in structural connection, high in strength, capable of effectively improving security, high in selectivity of installation mode, convenient to install, novel in appearance, and less influenced by extreme weather, so that work efficiency is ensured, the application range of the camera is improved, each component is high in structural stability, the final-period maintenance cost is low, and the reliability is high.

Owner:舟山市普陀金色阳光网络科技有限公司

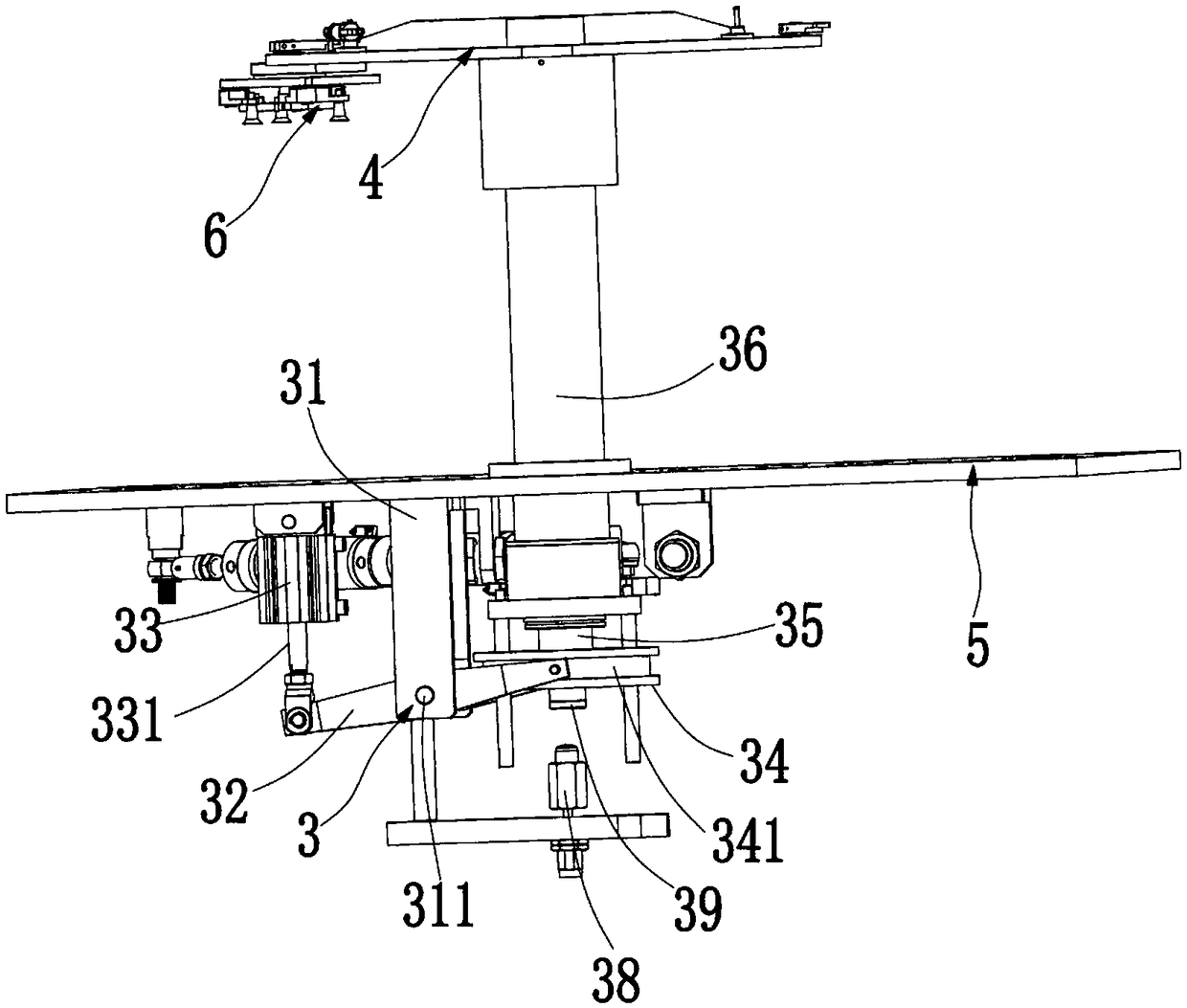

Pipeline rotary connector, cannon barrel direction adjusting mechanism and water cannon

ActiveCN105833453AStable structureImprove firmnessWeapon control systemsAdjustable jointsEngineeringMechanical engineering

The invention discloses a pipeline rotary connector, a cannon barrel direction adjusting mechanism and a water cannon. The water cannon is used for fire protection or naval vessels. The cannon barrel direction adjusting mechanism is arranged on the water cannon. The cannon barrel direction adjusting mechanism is realized through two pipeline rotary connectors mounted on a pipeline and is provided with a pipeline bending mechanism used for offsetting water flow lateral impact force. Each pipeline rotary connector comprises a female joint, a male joint, a ring cap, a worm and a motor, wherein the female joint and the male joint are clamped together through the ring cap, a pipeline cavity is formed in the female joint and the male joint, and the female joint and the male joint can rotate relatively. Each male joint is provided with a gear. Each worm and the corresponding motor are mounted on the corresponding female joint. Each motor can drive the corresponding male joint to rotate through the engagement function of an outer thread of the corresponding worm and the corresponding gear.

Owner:JIANGSU HENGDA POWER TECH DEV CO LTD

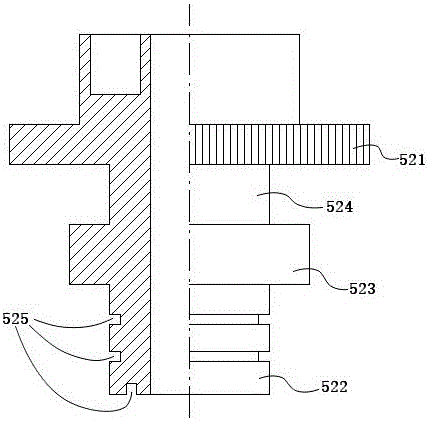

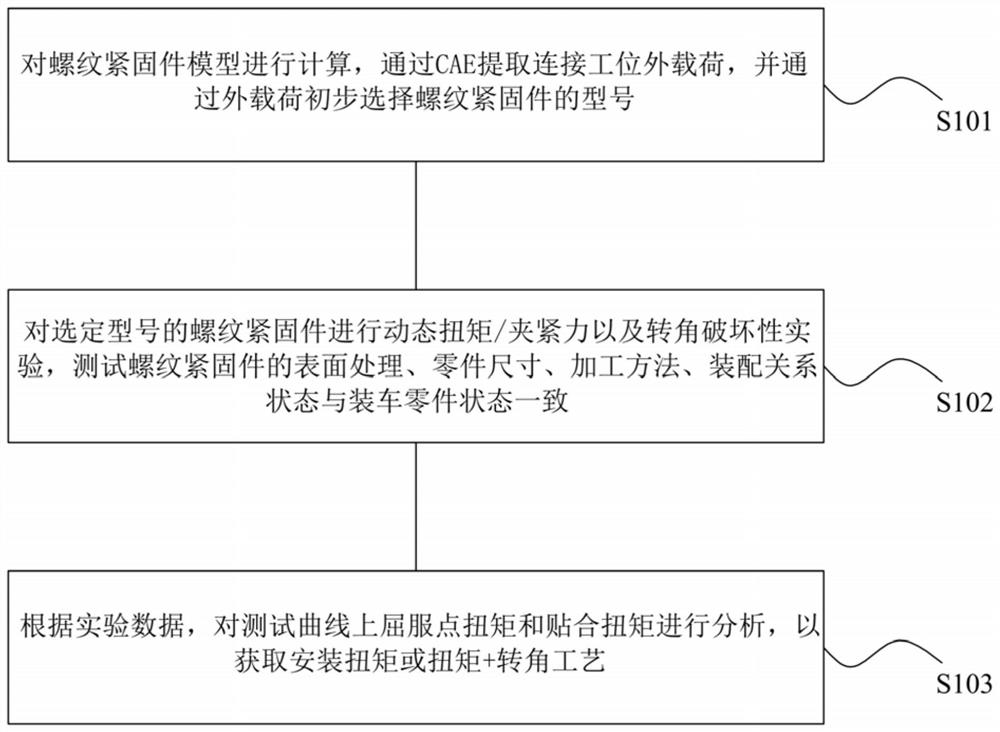

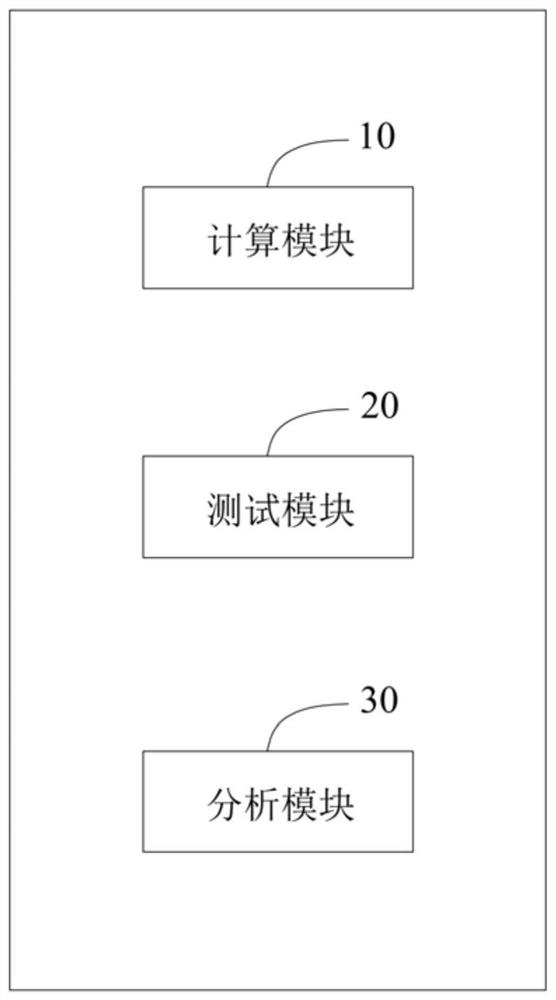

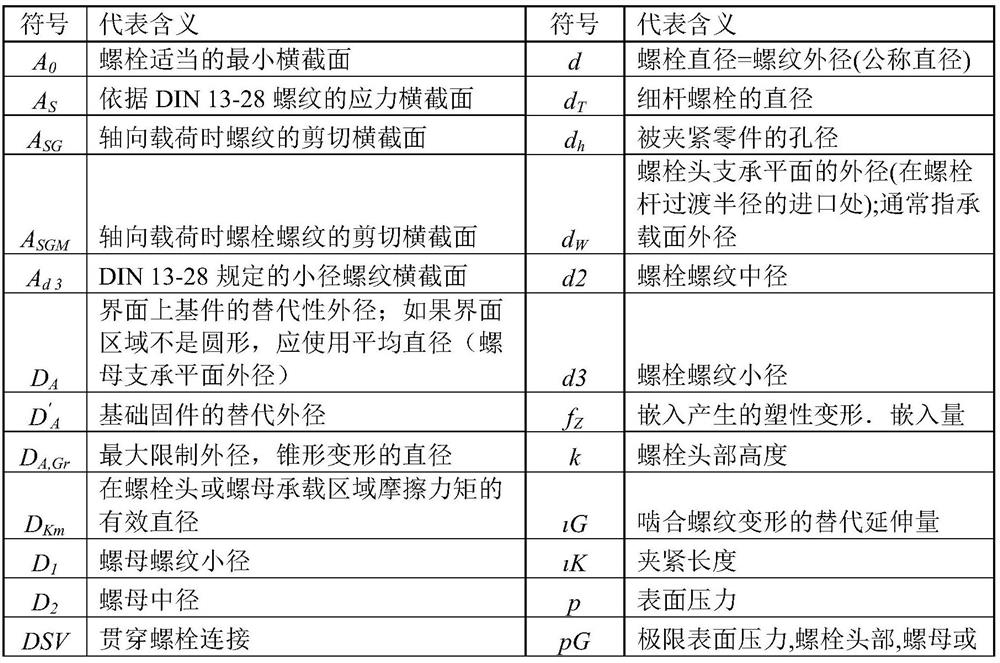

Threaded fastener design method and system

ActiveCN112765737ASmall degree of dispersionReduced risk of looseningGeometric CADScrewsExperimental testingScrew thread

The invention discloses a threaded fastener design method and system, and the method comprises the steps: carrying out the calculation of a threaded fastener model, extracting the external load of a connection station through CAE, and preliminarily selecting the model of a threaded fastener through the external load; carrying out dynamic torque / clamping force and corner destructive experiments on the threaded fastener of the selected model, wherein it is tested that the surface treatment, the part size, the machining method and the assembly relation state of the threaded fastener are consistent with the loading part state; and according to experimental data, analyzing the yield point torque and the fitting torque on the test curve to obtain the installation torque or the torque + corner process. According to the method, the model selection of the threaded fastener is carried out from the stress load, then the torque / clamping force + rotation angle test is carried out through the tool state part, so that the reasonable installation torque is formulated, and the loosening risk is reduced through theoretical calculation pre-judgment and actual part test forward design.

Owner:JIANGLING MOTORS

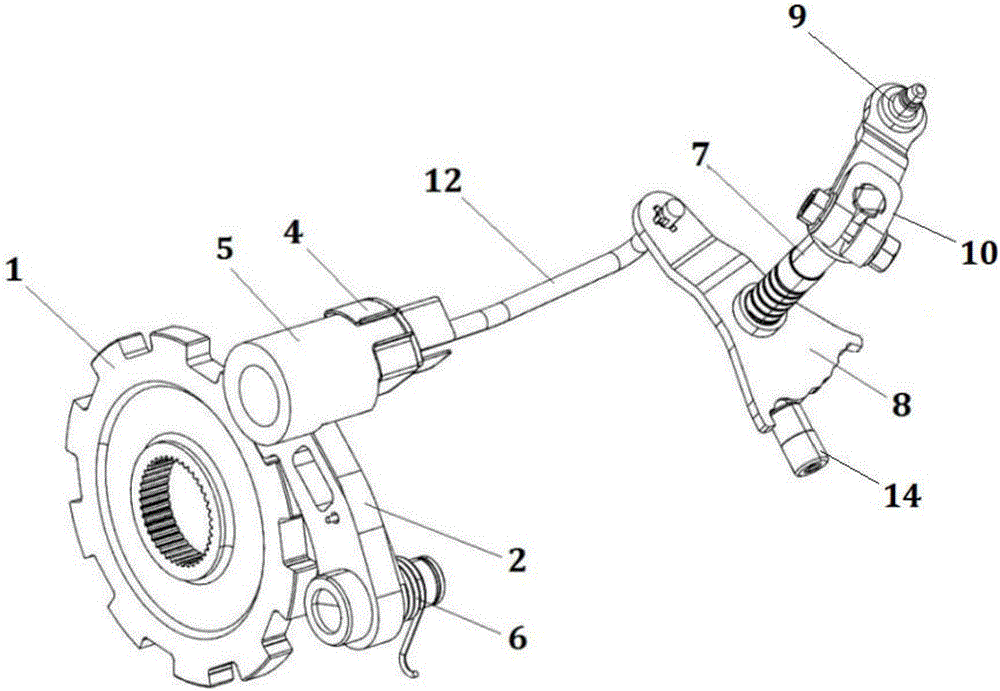

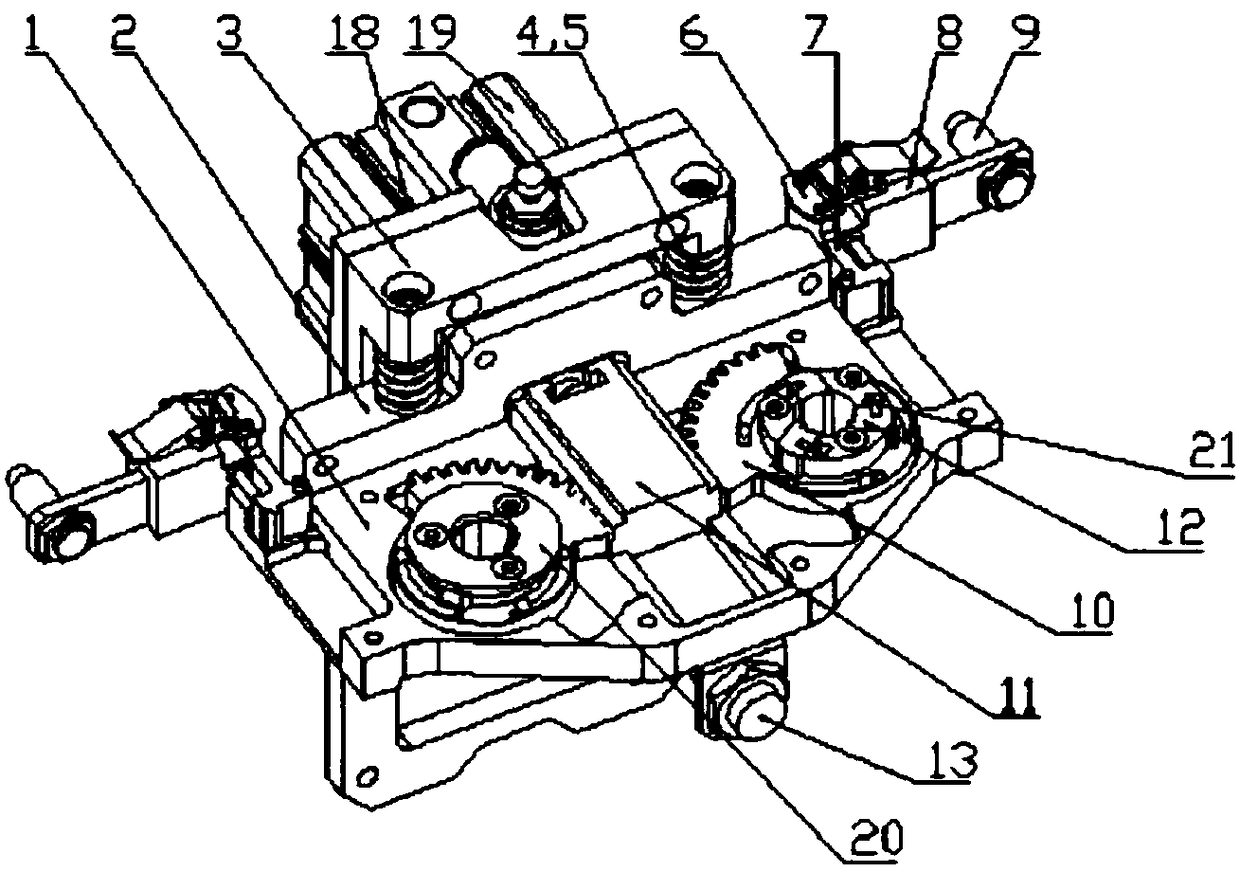

Automatic gearbox parking locking mechanism

ActiveCN105736693AReduce the number of partsReduced risk of looseningGearing controlParking spaceEngineering

The invention relates to an automatic gearbox parking locking mechanism, which comprises a parking gear, a parking pallet, an executing pin, a guide plate and a parking base, wherein the parking gear is arranged on a middle shaft of the a gearbox; the parking pallet is engaged with the parking gear; the executing pin is used for driving the parking pallet to be engaged with the parking gear; the guide plate is used for guiding the executing pin to move; the parking base is used for carrying the executing pin to stress; the guide plate is clamped and connected onto the parking base; the executing pin passes through the guide element; one end of the parking pallet is connected with a pallet pin in a sleeving way and rotates around the pallet pin; the other end of the parking pallet is rotationally arranged inside the gearbox; in addition, the parking pallet rotates between the locking position engaged with the parking gear and a release position disengaging from the parking gear. The automatic gearbox parking locking mechanism has the advantages that the structure is compact; the parts are few; the loosening risk is low.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

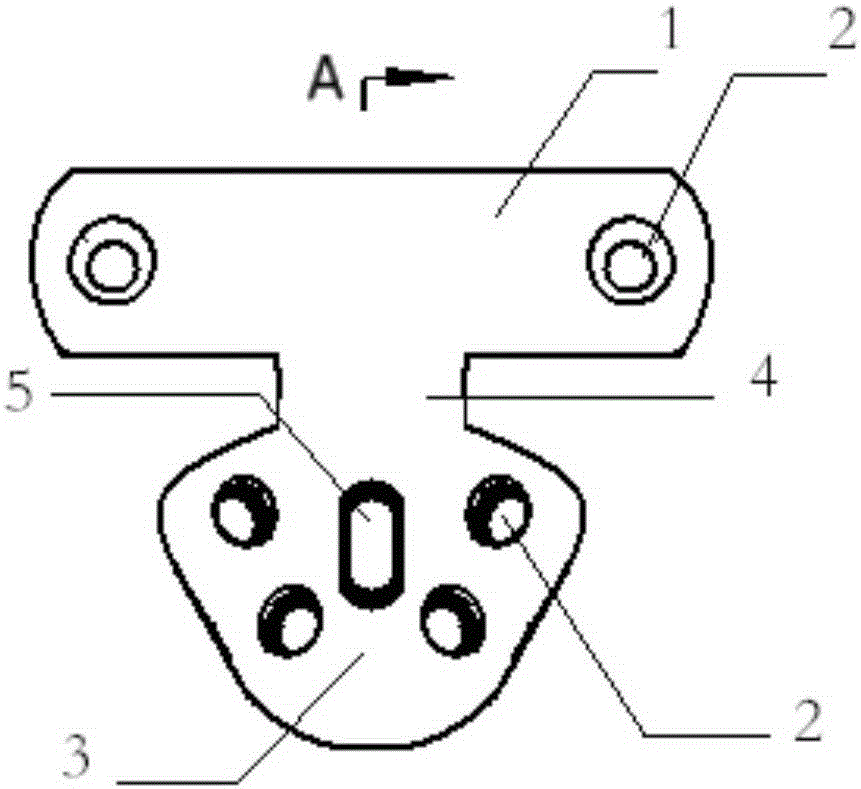

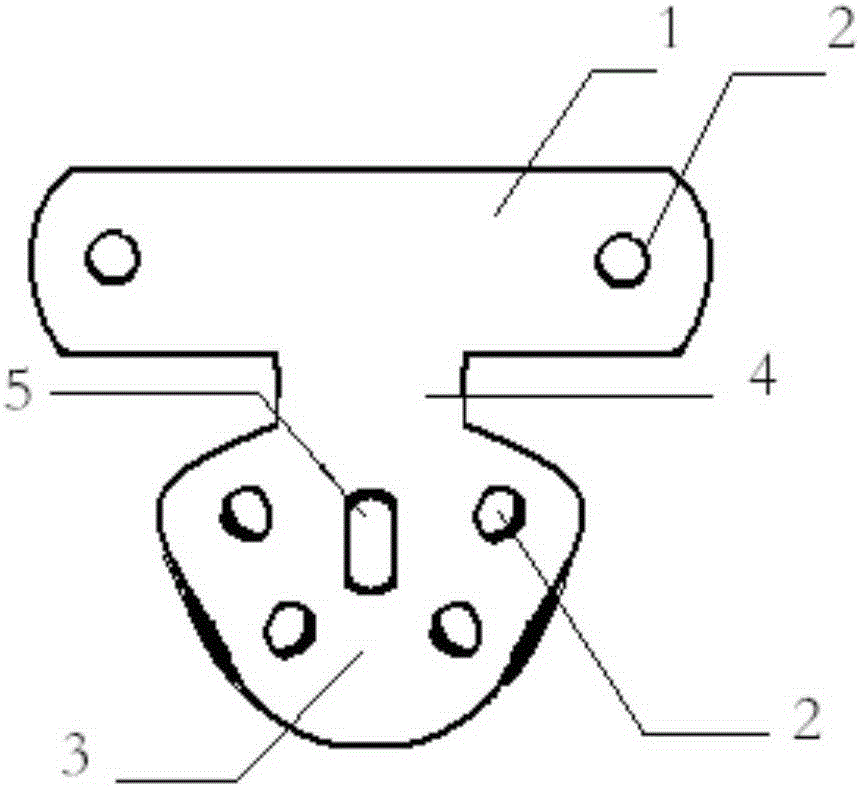

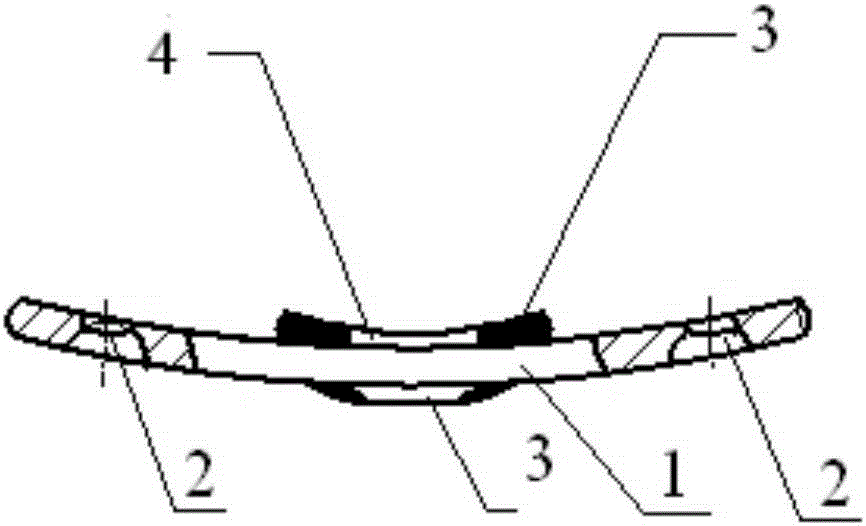

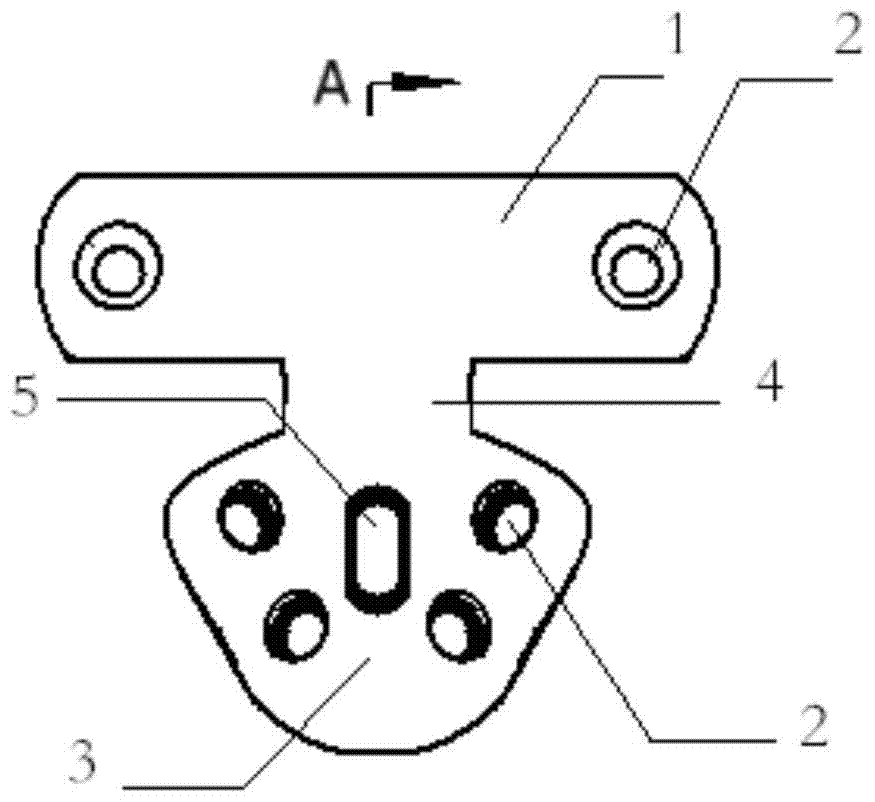

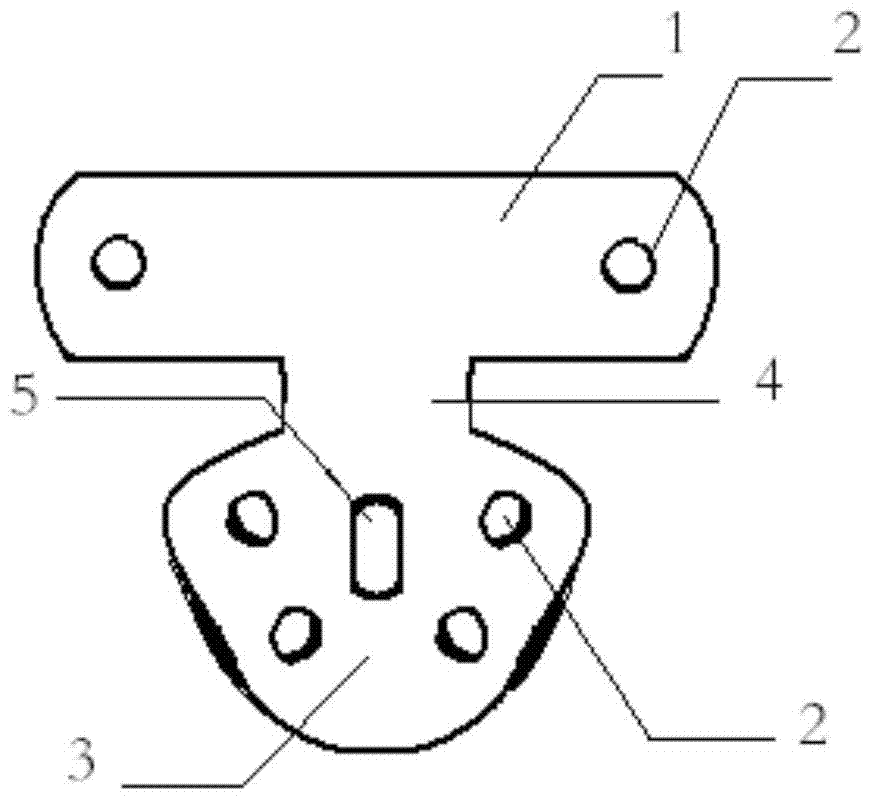

Atlantoaxial dislocation anterior anatomy template with automatic reduction function

ActiveCN105213007ADislocation playedGood reset fixation effectInternal osteosythesisBone platesAtlantoaxial dislocationIliac screw

The invention discloses an atlantoaxial dislocation anterior anatomy template with an automatic reduction function. The atlantoaxial dislocation anterior anatomy template comprises an atlas part, an axis part and a connecting part. The atlas part is in an arc shape, and symmetrical screw holes are designed in the two sides of the atlas part. The axis part is located below the back of the atlas part and matched with the front structure of the body of the axis, five screw holes are designed in the axis part, four screw holes are symmetrically located in the two sides, and the other screw hole is located in the middle and is an oblong sliding screw hole. The atlas part and the axis part are connected through the connecting part. A screw slides in the sliding screw hole, so that the atlantoaxial dislocation reduction effect is achieved; through screw fixing, the atlantoaxial reduction purpose is achieved, the form of the template is completely matched with the anatomic form of the atlas and the axis, a higher degree of fit is achieved, and the template is attractive in appearance and good in reduction effect.

Owner:THE SECOND AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

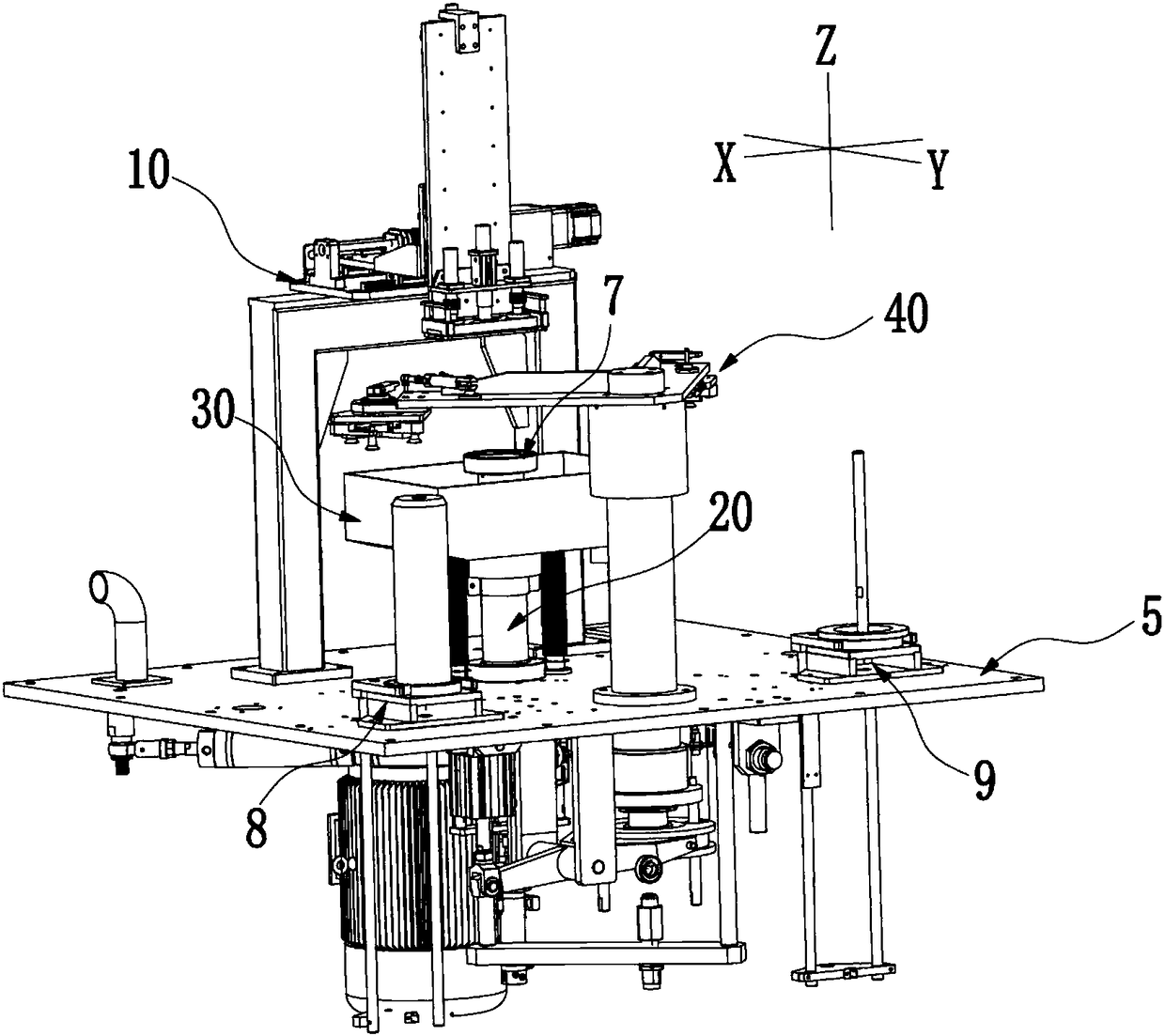

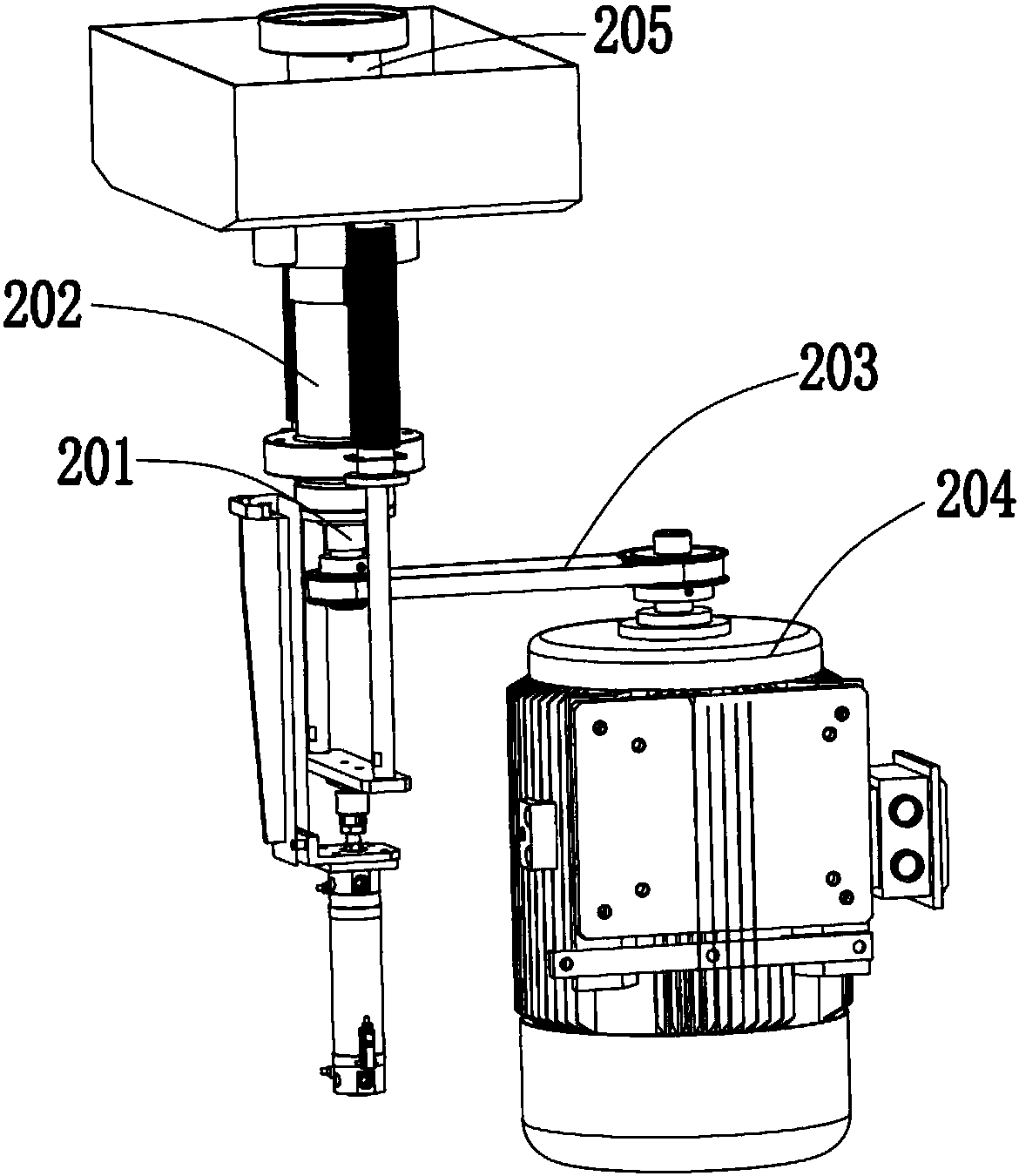

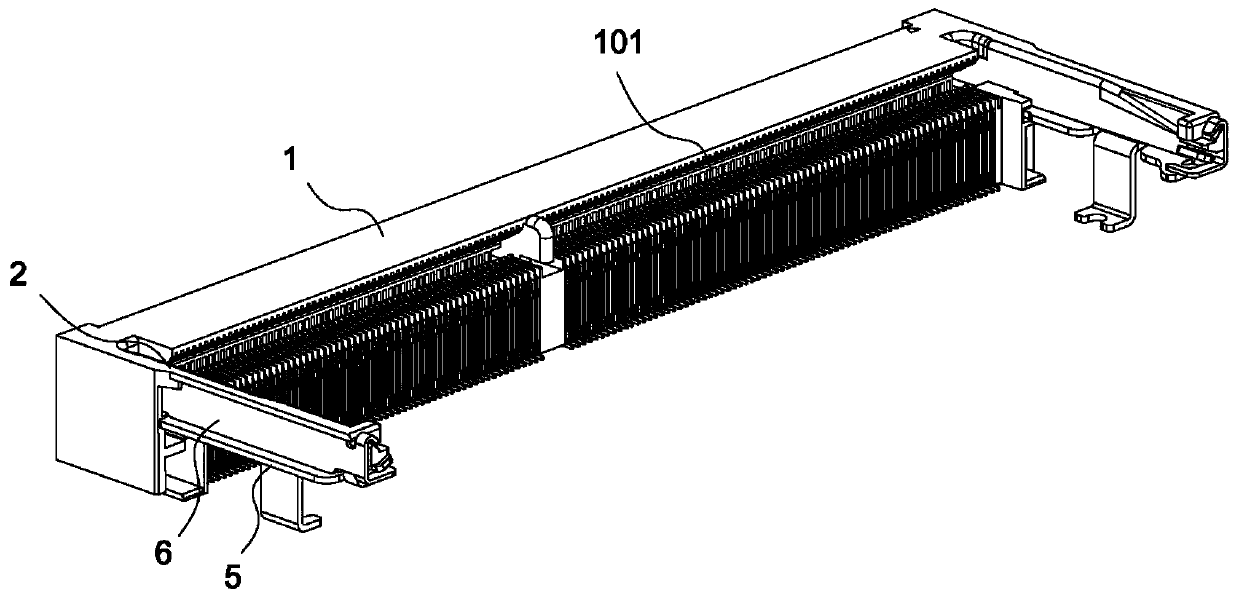

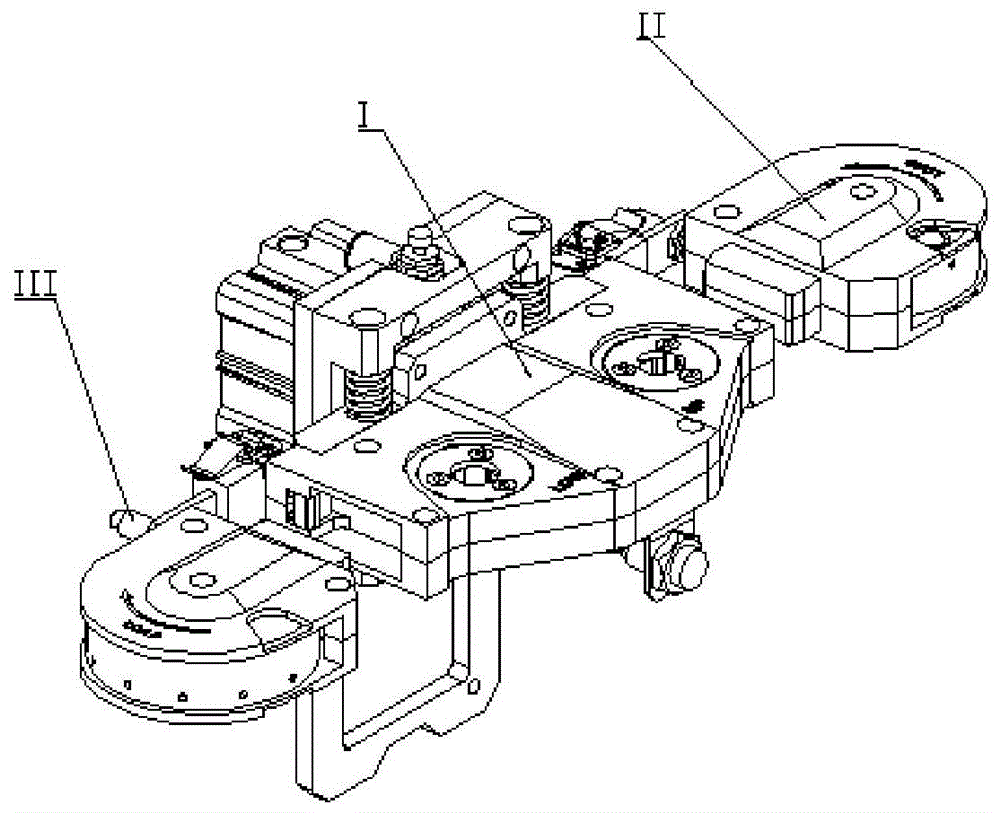

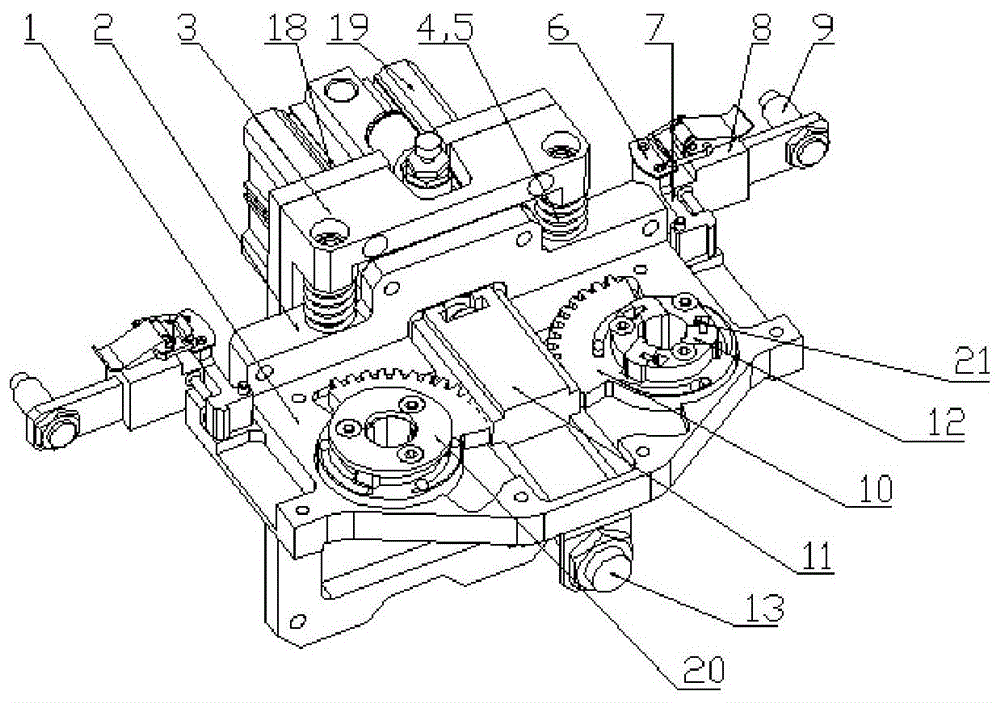

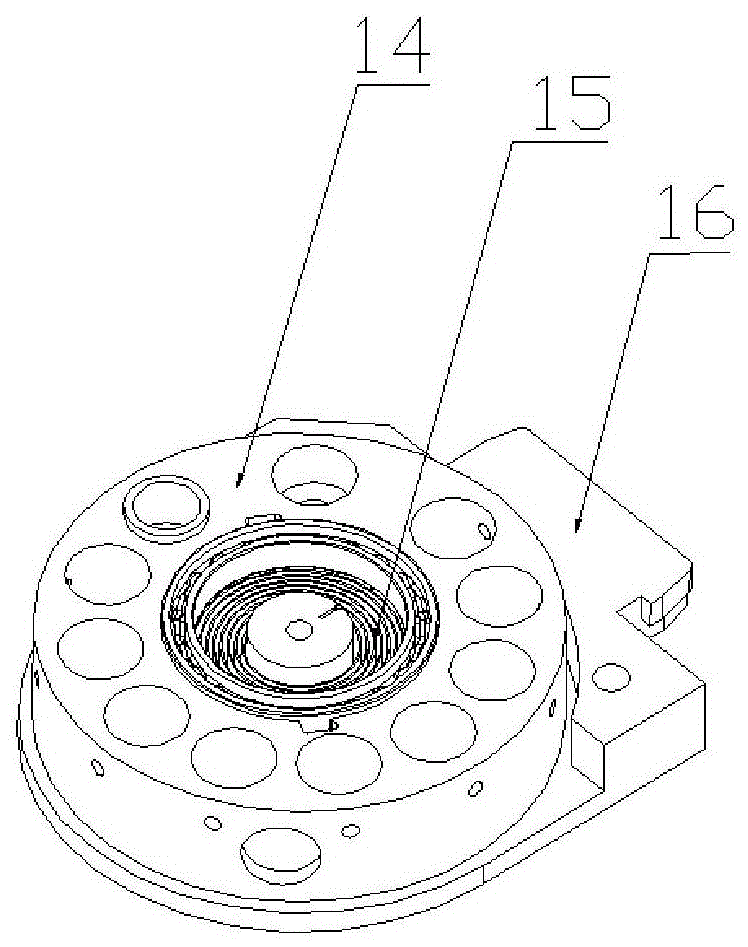

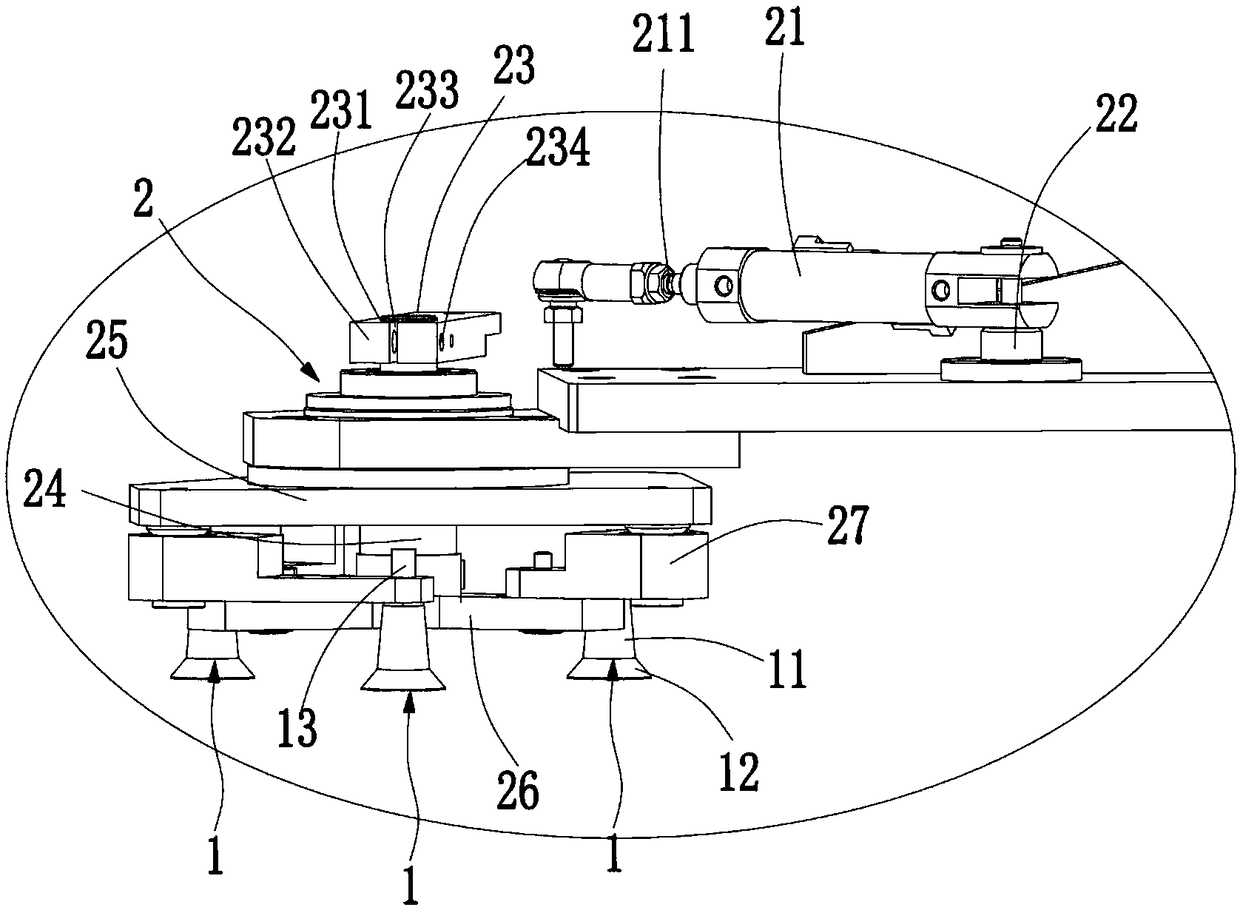

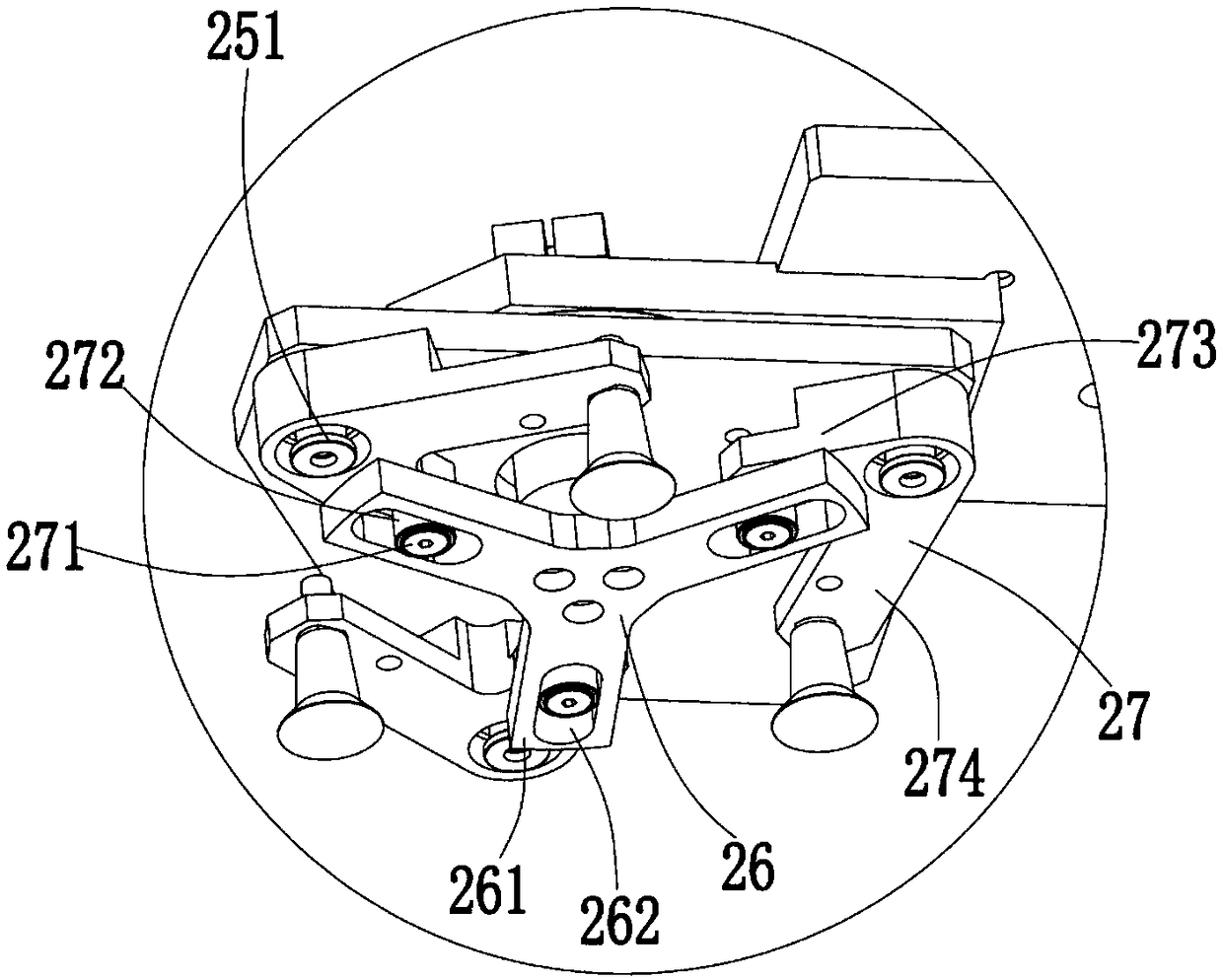

Surface wiping machine for disc-shaped parts

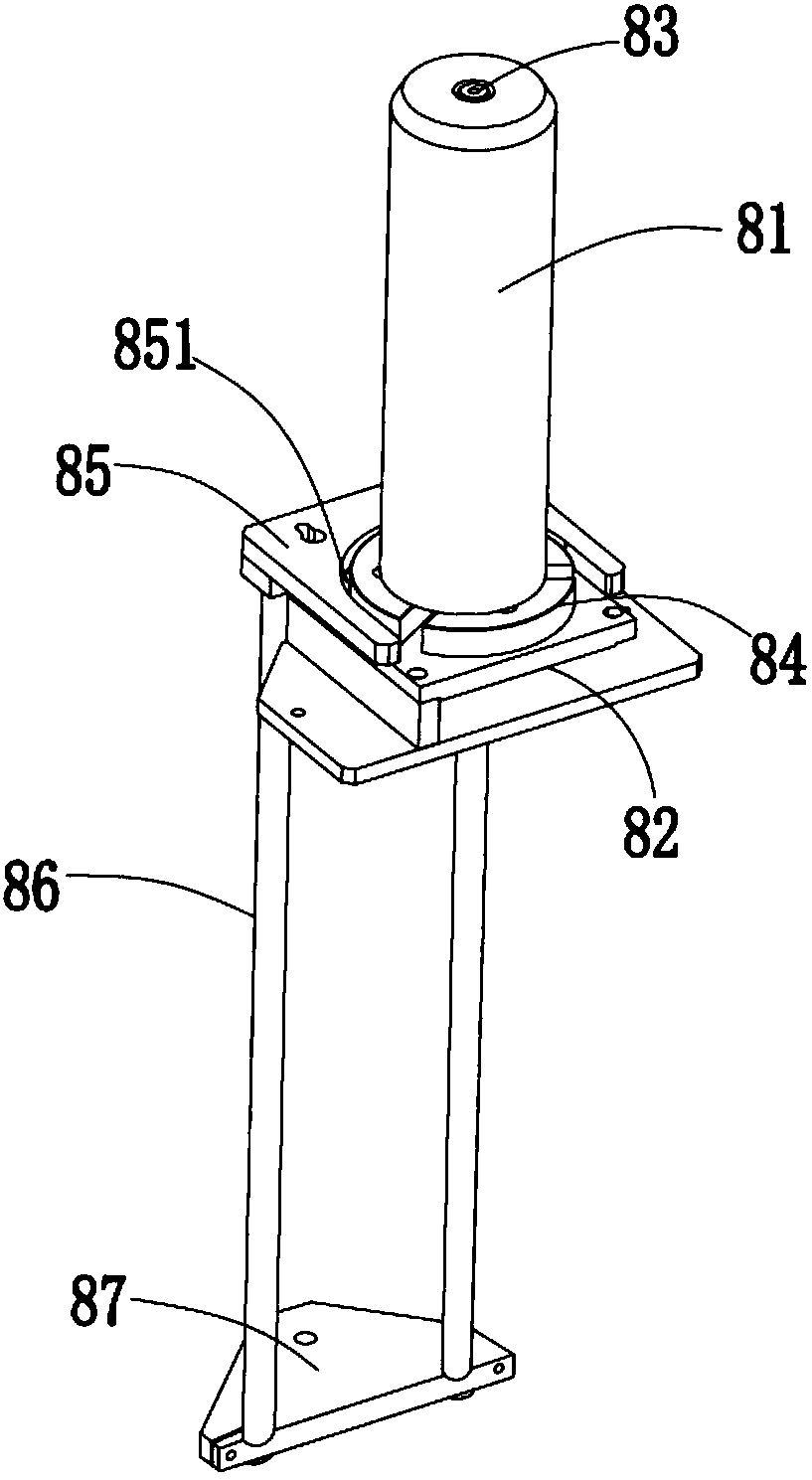

PendingCN108515417AExquisite designSimple structureGrinding machinesGrinding work supportsEngineeringAutomation

The invention discloses a surface wiping machine for disc-shaped parts. The surface wiping machine comprises a part storage tank, a part supply machine, a part recovery machine, a feeding and discharging robot and a wiping device, wherein the part storage tank is provided with a limiting groove used for storing parts; a plurality of to-be-wiped parts can be stacked on the part supply machine, andthe uppermost part is located at the to-be-clamped altitude; the part recovery machine is used for stacking multiple wiped parts; the feeding and discharging robot is provided with clamping jaws whichcan make contact with the outer circumferential surfaces of the parts and are matched with one another to clamp the parts, and can move between the part supply machine, the part storage tank and thepart recovery machine; and the wiping device is used for wiping a part placed on the part storage tank. According to the scheme, the independent stations can be organically combined through the feeding and discharging robot to form an automatic system, so that the automation degree is high, and the machining efficiency is improved; and meanwhile, the clamping jaws of the feeding and discharging robot make contact with the circumferential surfaces of the disc-shaped parts, so that damage to the upper and lower surfaces of the parts is avoided; and meanwhile, the problem that the parts are contaminated and scratched again after being wiped can be solved, and the wiping effect and quality of the parts can be guaranteed.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

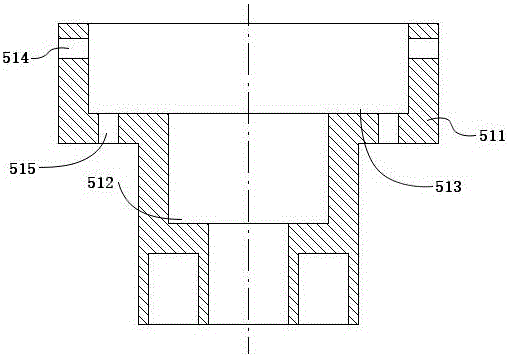

Tibial plateau support and knee-joint prosthesis applying same

The invention relates to the technical field of medical prosthesis, and discloses a tibial plateau support and knee-joint prosthesis applying the same. The tibial plateau support comprises a plateau support supporting part and a plateau support connecting part, wherein the plateau support supporting part comprises a top surface used for being connected with a liner of the knee-joint prosthesis anda bottom surface used for being attached to an osteotomy plane of human body tibia; and one end of the plateau support connecting part is fixedly connected with the bottom surface, and the other endof the plateau support connecting part is used for being implanted into a medullary cavity of the human body tibia to be connected with the human body tibia. The cross section structure of the bottomsurface is the same as the osteotomy plane of human body tibia. The tibial plateau support is more stable after implantation.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Ramie peeling device and feeding mechanism thereof

PendingCN109355712AReliable clamping and fixingAvoid the phenomenon of being directly exportedMechanical fibre separationEngineeringChain link

The invention discloses a ramie peeling device and a feeding mechanism thereof. The ramie peeling device comprises an upper clamping assembly and a lower clamping assembly, wherein the upper clampingassembly comprises an upper clamping chain and an upper driving mechanism for driving the upper clamping chain to move; the lower clamping assembly comprises a lower clamping chain and a lower drivingmechanism for driving the lower clamping chain to move; the upper clamping chain and the lower clamping chain are always in a parallel opposite clamping states on a conveying line corresponding to ramie; the upper clamping chain and the lower clamping chain have the same linear speeds on the conveying line; an elastic pressure bar is fixedly arranged on the clamping surface of the upper clampingchain; and a concave clamping plate matched with the elastic pressure bar is arranged on the clamping surface of each chain link of the lower clamping chain. The feeding mechanism transversely pressesthe ramie into the concave clamping plates through the elastic pressure bar, and then the ramie can be clamped and fixed more stably and reliably, so that the phenomenon of different cleanness degrees of peeling of the ramie in the same batch is avoided.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

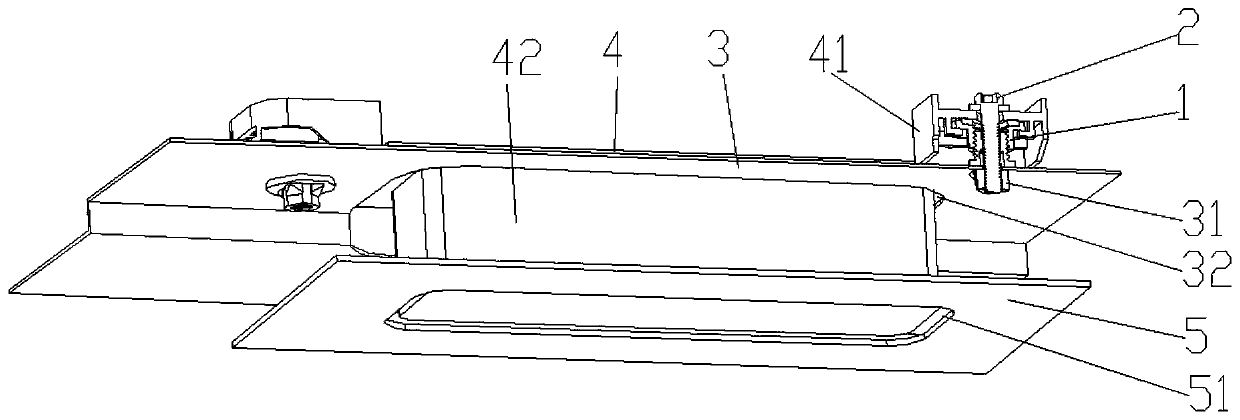

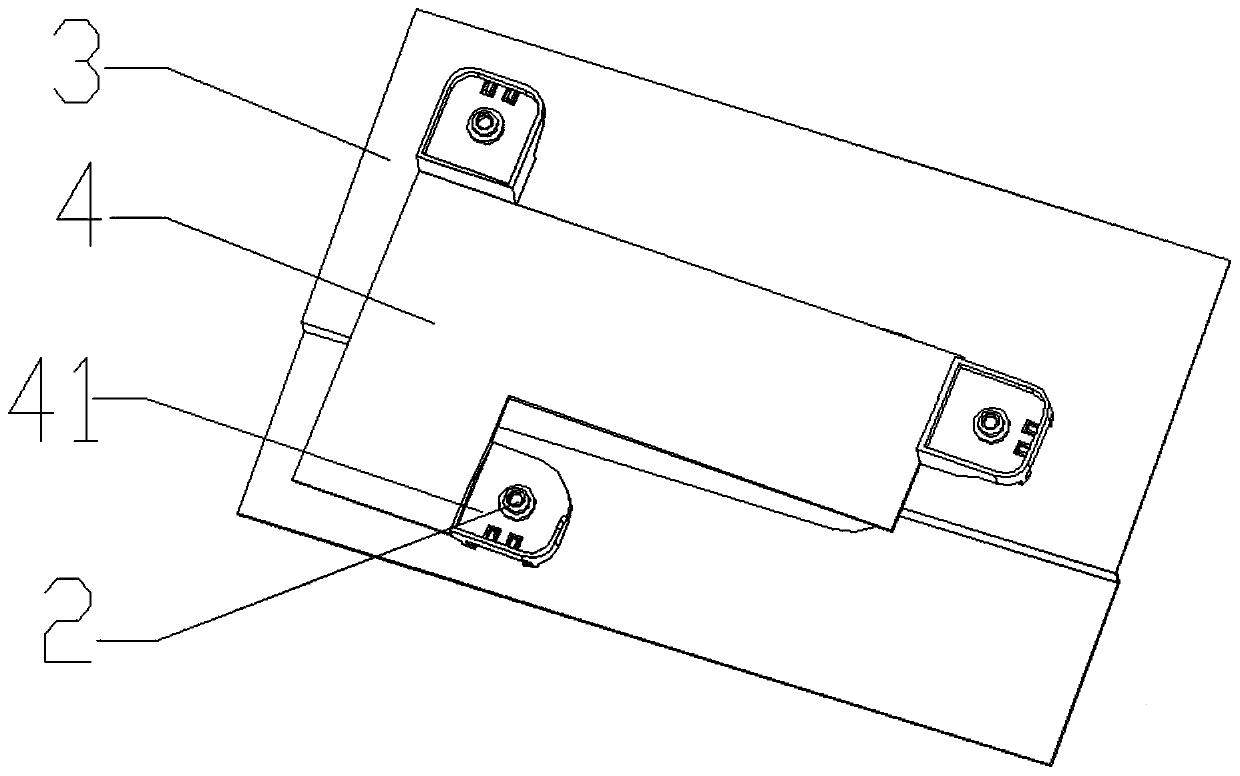

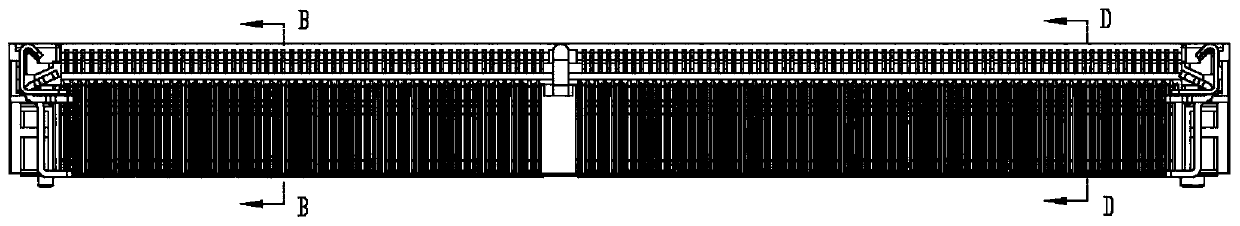

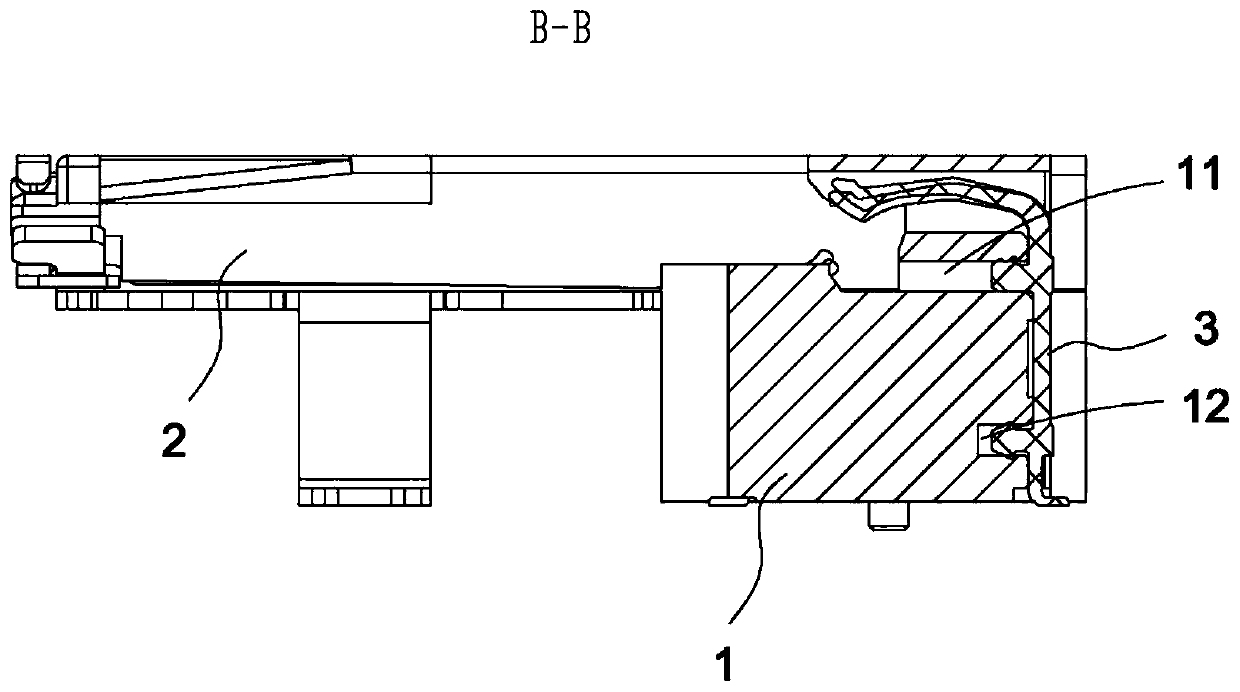

DDR connector

PendingCN110635272AReduce the overall heightEasy to assembleSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

The invention provides a DDR connector comprising a connector. The connector comprises a socket and a bracket. The socket is internally provided with slots. One end of the bracket close to the socketis provided with a first jack and a second jack. A support plate is inserted into the first jack. The support plate comprises a first plug-in part, a backing plate part, a support part, a mounting part and a first bending part. A side baffle is inserted into that second jack. The side baffle is located on the outer side of the bracket. The side baffle comprises a second plug-in part, a side platepart, a second bending part and a third bending part. The tail end of the bracket is provided with a clamping part. The second bending part is buckled and connected with the upper end of the clampingpart. The third bending part is clamped between the first bending part and the support part. The DDR connector has simple structure, small occupied volume and easy assembling.

Owner:FCI CONNECTORS DONGGUAN

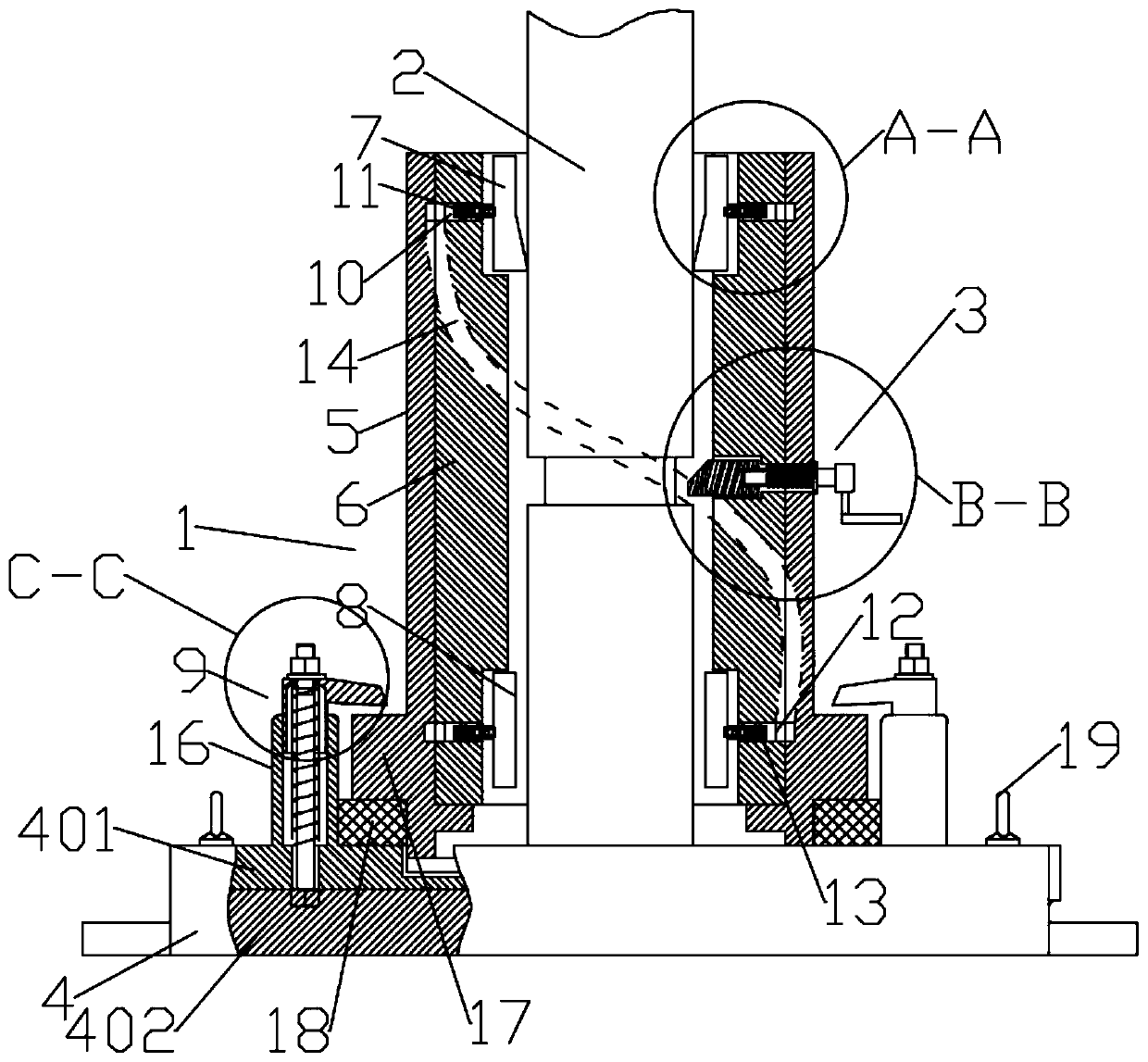

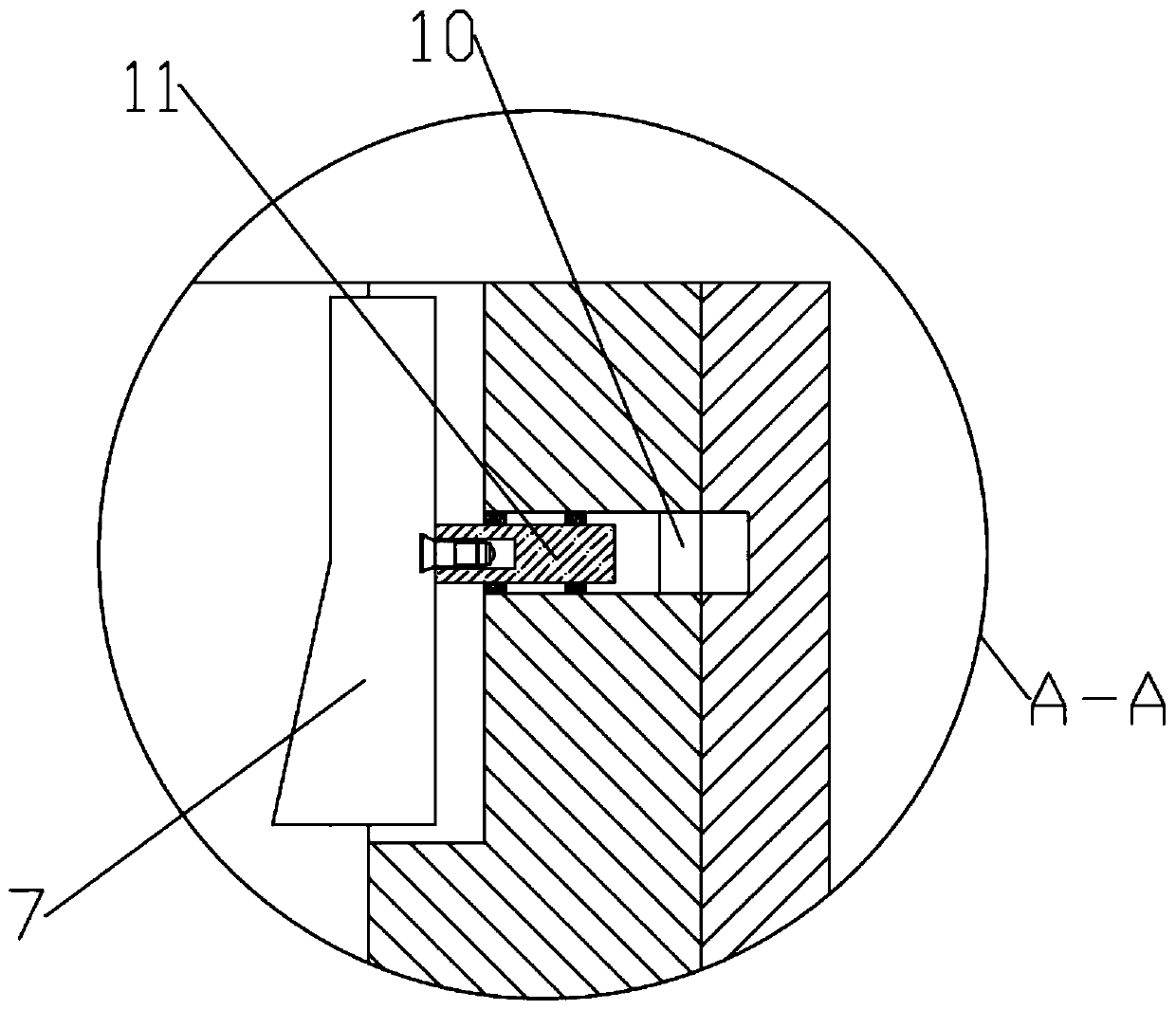

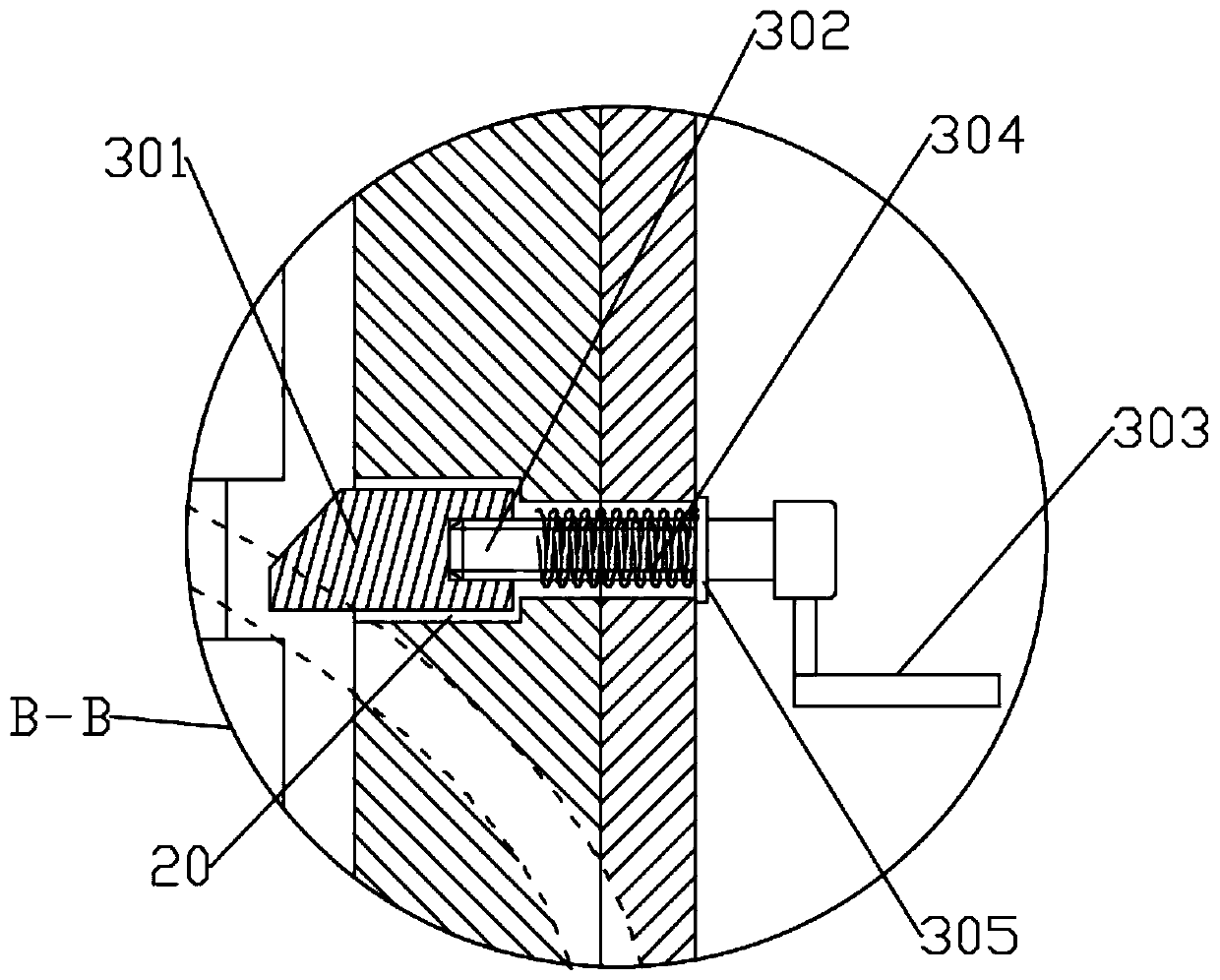

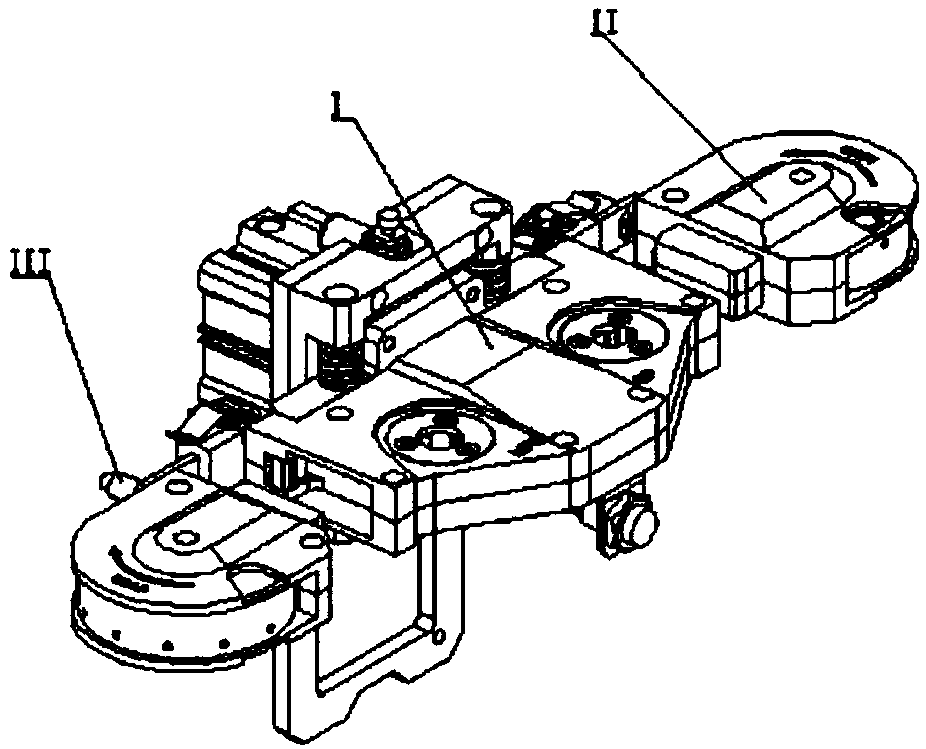

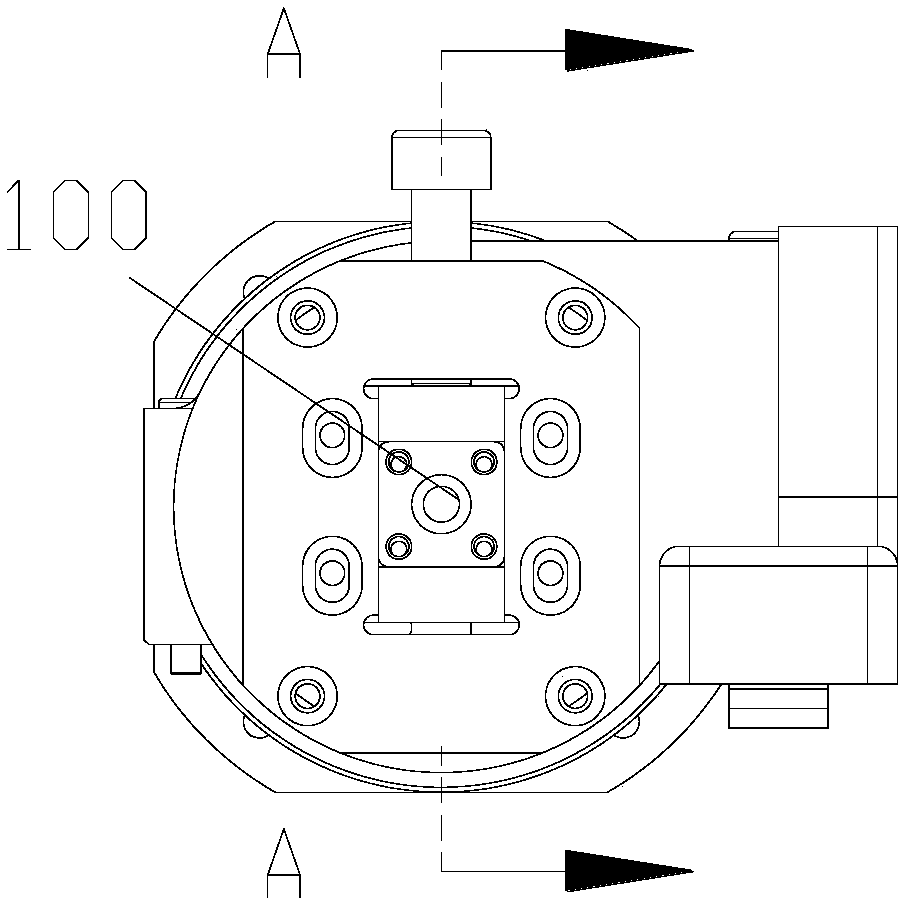

An independent electrode cap automatic replacement equipment

ActiveCN103465006BEasy upgrade functionImprove efficiencyMetal working apparatusResistance welding apparatusElectricityBiomedical engineering

The invention relates to the field of automatic production of automobiles, in particular to an independent automatic electrode cap replacement unit comprising an electrode cap removal unit, an electrode cap storage unit and a sensing detection unit. The electrode cap storage unit and the sensing detection unit are disposed on two sides of the electrode cap removal unit and are connected in a quick plugging manner. The sensing detection unit comprises an electrode cap removal detection sensor, two electrode cap amount detection sensors and two travel detection sensors. The independent automatic electrode cap replacement unit has the advantages that the unit which is highly modular can be combined with any automatic grinder to allow for automatic die repair and cap replacement, and the function can be updated for customers still replacing caps with hands; the twist and pull cap removal technology is utilized innovatively, efficiency and reliability are improved greatly, upper and lower electrode caps are removed respectively with the cap replacement unit in different rotation directions, the risk of electrode bar looseness due to cap removal torque can be reduced, the electrode cap storage unit can be removed freely, and the size of the whole cap replacement unit is reduced.

Owner:上海卡格机电设备有限公司

Detachable wind-resistant street lamp

ActiveCN110848616ADeflection reduction and correctionAchieve a stable purposeMachine framesLighting support devicesStructural engineeringShock resistance

The invention relates to a detachable wind-resistant street lamp, and belongs to the technical field of street lamps. The detachable wind-resistant street lamp comprises a fixed pile and a lamp pole vertically connected to the fixed pile in an inserted mode, wherein a clamping structure for clamping an ejector rod is further arranged on the fixed pile; the fixed pile comprises a base, an outer sleeve, an inner sleeve, a plurality of upper abutting pieces and a lower abutting piece; the outer sleeve is fixedly arranged on the base through a buffer structure; the inner sleeve is arranged in theouter sleeve in a sleeving mode; the multiple upper abutting pieces are arc-shaped; and the inner wall of the upper end of the inner sleeve is arranged along the circumference. The street lamp provided by the invention can guarantee the wind resistance and shock resistance of the detachable street lamp, so that the stability of the structure is increased.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

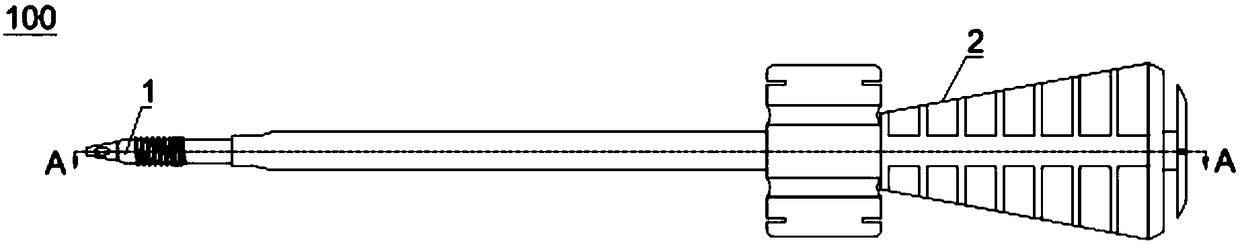

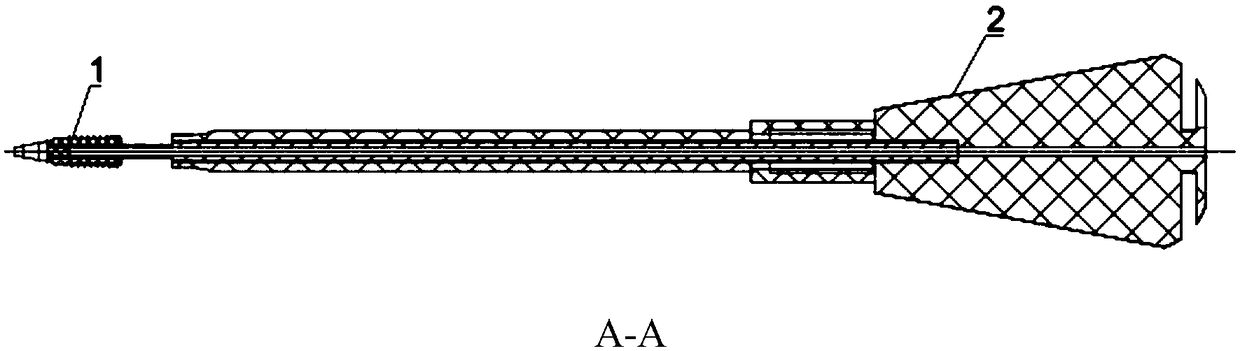

Interbody fusion cage driver

PendingCN110327139ANot subject to torqueReduced risk of looseningJoint implantsSpinal implantsSpinal cageEngineering

The invention provides an interbody fusion cage driver. The interbody fusion cage driver comprises a clamping structure and a force applying structure, wherein the clamping structure is used for clamping an interbody fusion cage and comprises a connecting part and a clamping element connected to one end of the connecting part; the force applying structure is used for applying force to the clampingelement to enable the clamping element to perform clamping under the force; and the connecting part is connected with the force applying structure. The interbody fusion cage driver is simple in structure, and the condition that fixation and screwing-out structures of the interbody fusion cage are realized by threads during traditional implantation of the interbody fusion cage is avoided; in the whole interbody fusion operation, the interbody fusion cage does not receive torsion action; the risk of looseness of the implanted interbody fusion cage is reduced; the interbody fusion cage driver has high universality and can realize clamping and loosening effects on multiple interbody fusion cages; and the functions of clamping and loosening the interbody fusion cages can be realized quickly, the time cost for screwing in and out of threads is saved, and the operation time is shortened.

Owner:TIANJIN ZHENGTIAN MEDICAL INSTR CO LTD

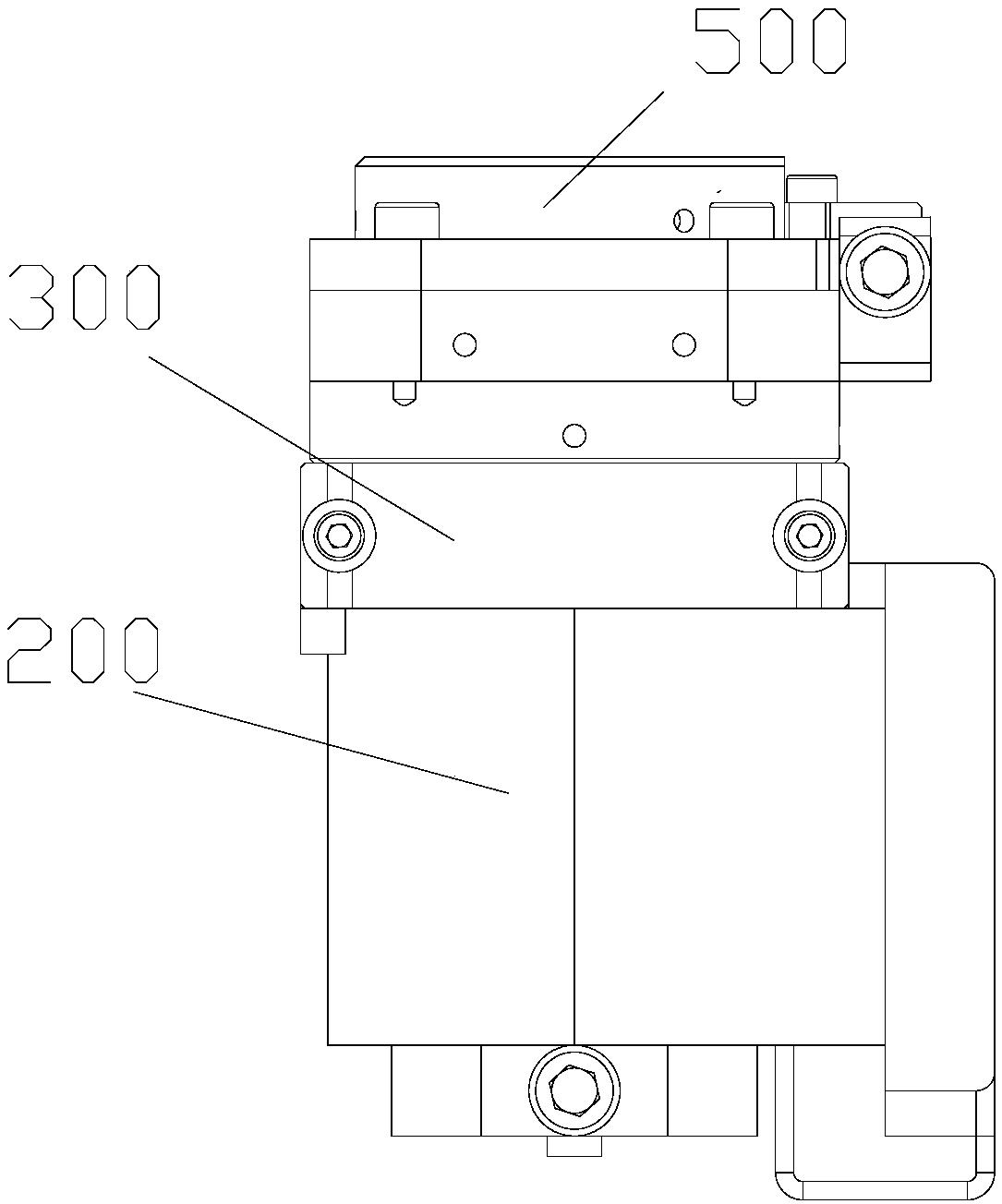

Novel automatic electrode cap replacing device

InactiveCN108188705AReduced risk of looseningFirmly connectedMetal working apparatusEngineeringBiomedical engineering

The invention relates to a novel automatic electrode cap replacing device. The novel automatic electrode cap replacing device comprises a cap disassembling mechanism, two groups of storage mechanismsand a detection mechanism, wherein the two groups of storage mechanisms are respectively arranged on two sides of the cap disassembling mechanism; the detection mechanism is arranged on the cap disassembling mechanism; the two groups of storage mechanisms are connected with the cap disassembling mechanism in a rapid insertion manner. The novel automatic electrode cap replacing device has the beneficial effects that the device is simple in structure and convenient to operate, and is stable and reliable; the yield and the quality are greatly improved; the device is highly structured and can be combined with any one automatic repairing and grinding machine; the functions of automatically repairing and replacing the caps can be achieved; through rotation and downward movement of gears and clamping parts, electrode caps can be separated from electrode rods; the efficiency and the reliability of the equipment can be greatly improved; spring clamps are arranged, so that the storage mechanismscan be more reliably connected with the cap disassembling mechanism.

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

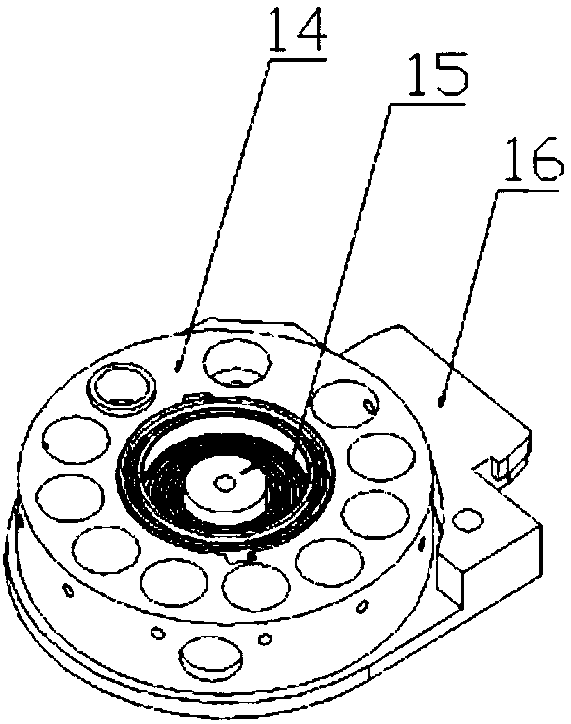

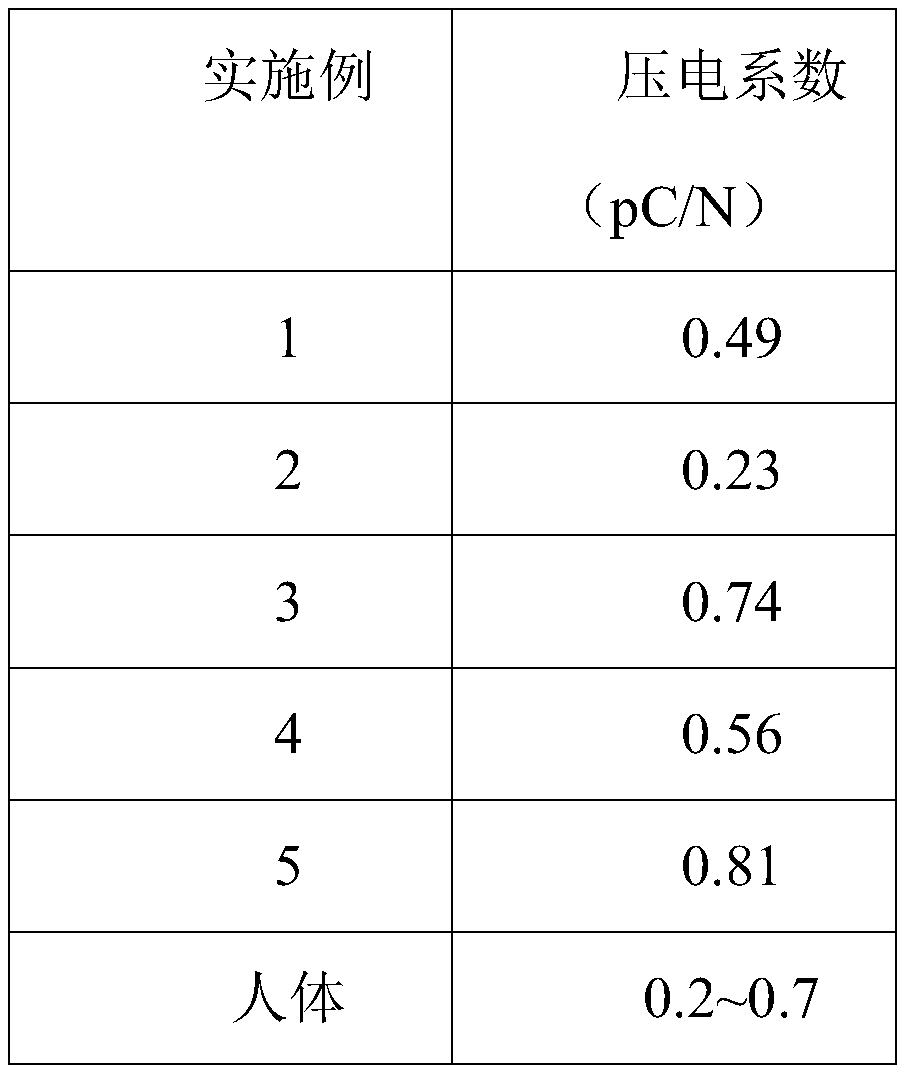

Preparation method of biopiezoelectric coating on titanium alloy surface

InactiveCN110013565AWith piezoelectric propertiesBiologically activeElectrolytic inorganic material coatingSurface reaction electrolytic coatingOsseointegrationTitanium alloy

The invention discloses a preparation method of biopiezoelectric coating on titanium alloy surface. According to the preparation method of the biopiezoelectric coating on the titanium alloy surface, perovskite-structured nanotube coating is prepared on surface of titanium alloy by adopting an anodic oxidation method combined with hydrothermal reaction; and then, the perovskite-structured nanotubecoating is compounded with hydroxyapatite, thereby forming biopiezoelectric coating on the surface of the titanium alloy. The biopiezoelectric coating on the titanium alloy surface prepared by the preparation method has piezoelectric effects capable of promoting osteogenic differentiation, and is excellent in biological activity; and thus, the biopiezoelectric coating on the titanium alloy surfaceis capable of effectively accelerating bone repair process so as to shorten treatment cycle. Moreover, the biopiezoelectric coating on the titanium alloy surface can form effective osseointegration with tissues near the implantation site, thereby reducing risk of loosening.

Owner:XIAN UNIV OF TECH

Drawstring connector and assembly applying same

PendingCN113285305AReduced risk of looseningImprove butt retentionCoupling device detailsTwo-part coupling devicesButt jointElectrical and Electronics engineering

The invention discloses a drawstring connector, which comprises an insulating body, a plurality of conductive terminals, a movable component, an elastic piece and a drawstring, wherein the insulating body comprises a main body part, and the main body part comprises a first end wall and a second end wall; the movable component is at least partially mounted in the main body part; the movable part comprises a first lock catch protrusion protruding out of the first end walll and the drawstring is connected with the movable component. The drawstring is configured to drive the movable component to move in the moving direction. The drawstring connector comprises a second lock catch protrusion protruding out of the second end wall. The first lock catch protrusion and the second lock catch protrusion are used for being buckled with lock catch holes of a butt-joint connector, and then the butt-joint holding force when the butt-joint connector is in butt joint is improved. The invention further discloses a drawstring connector assembly with the drawstring connector.

Owner:DONGGUAN LUXSHARE TECH CO LTD

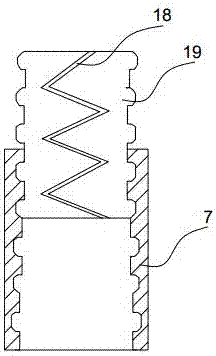

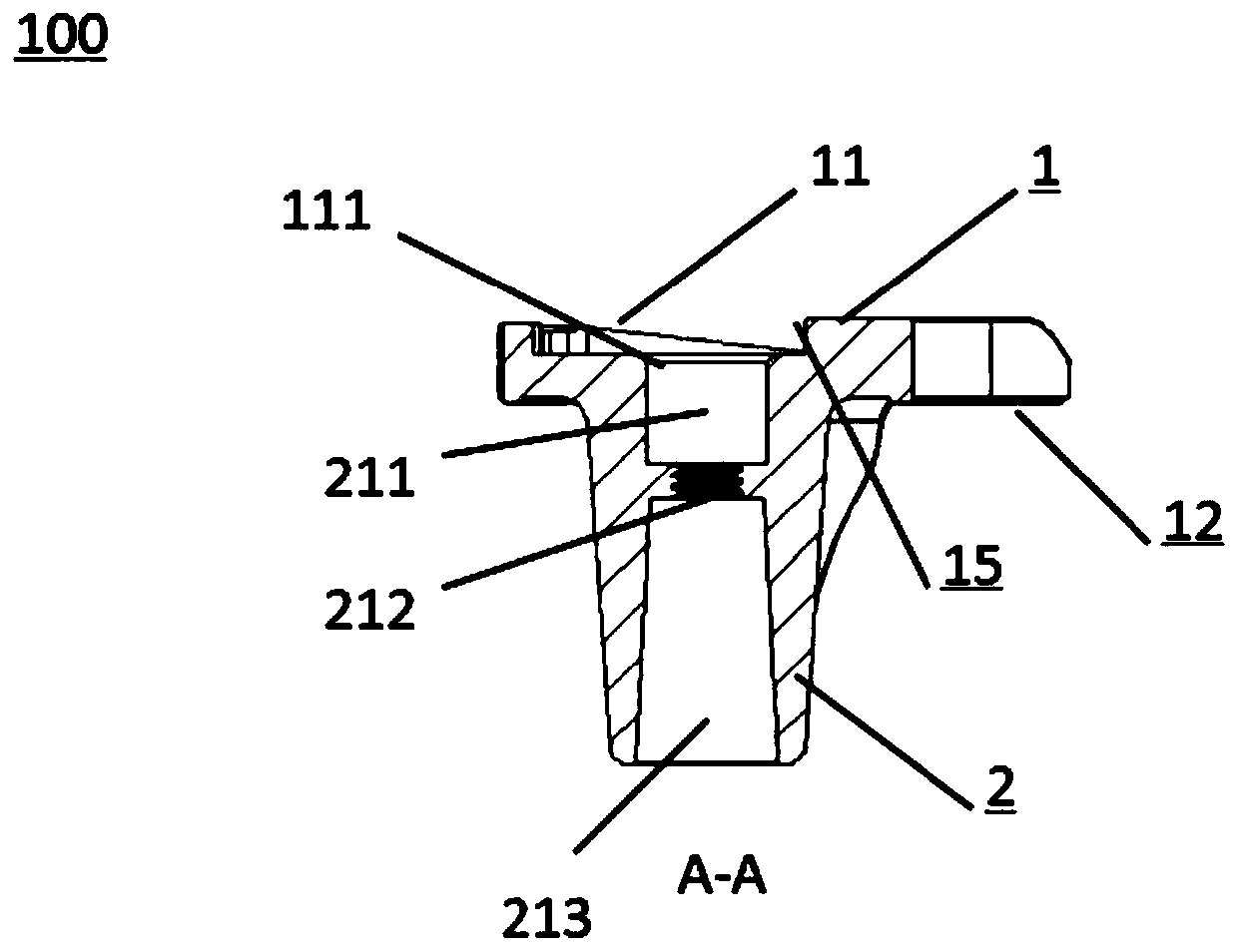

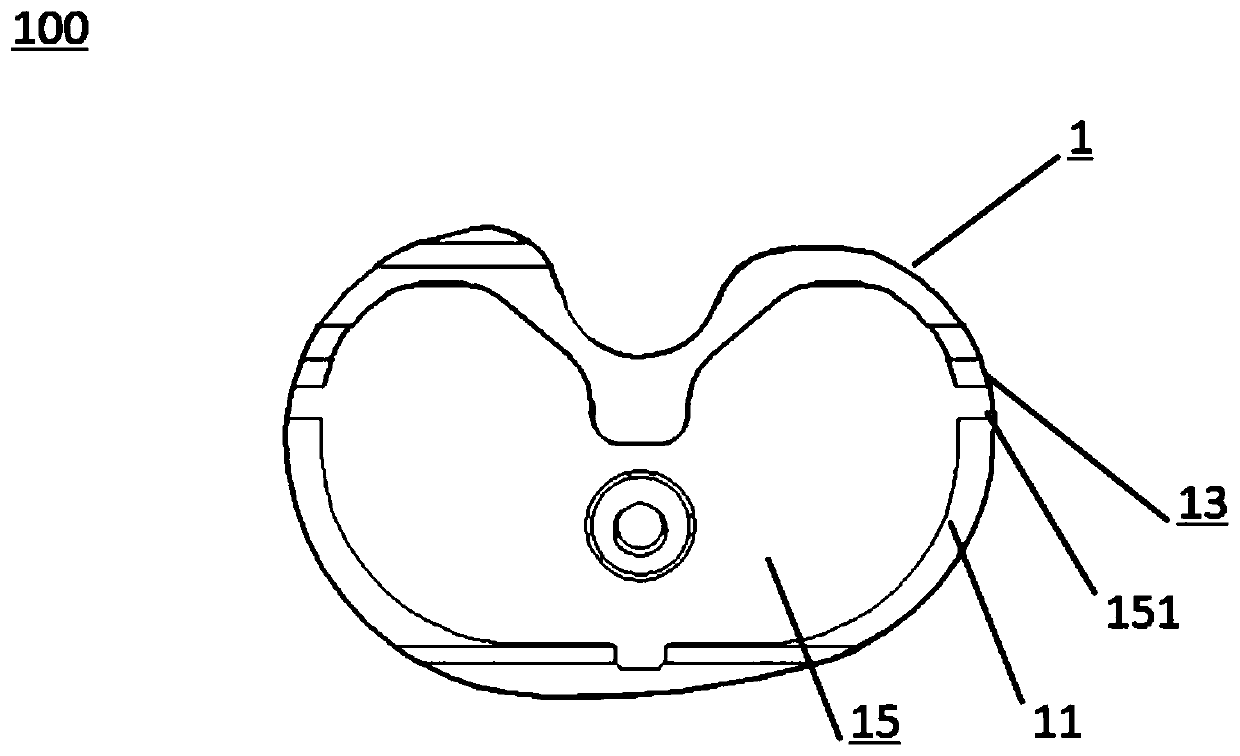

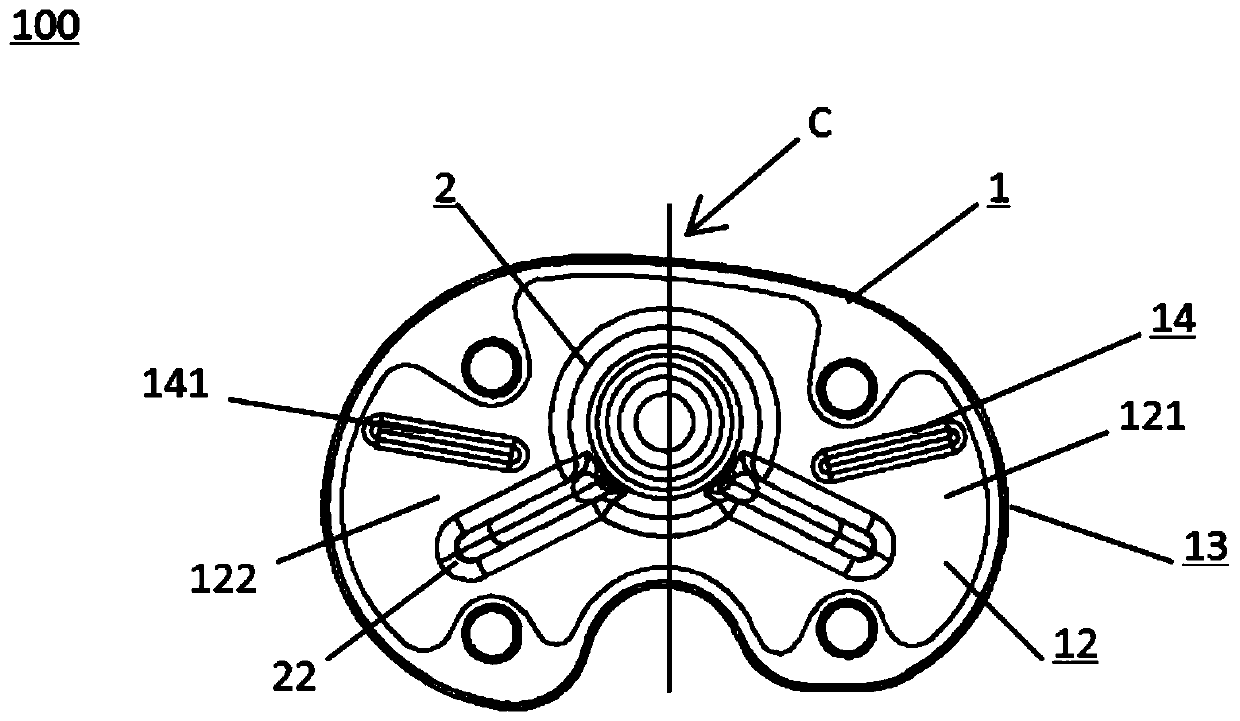

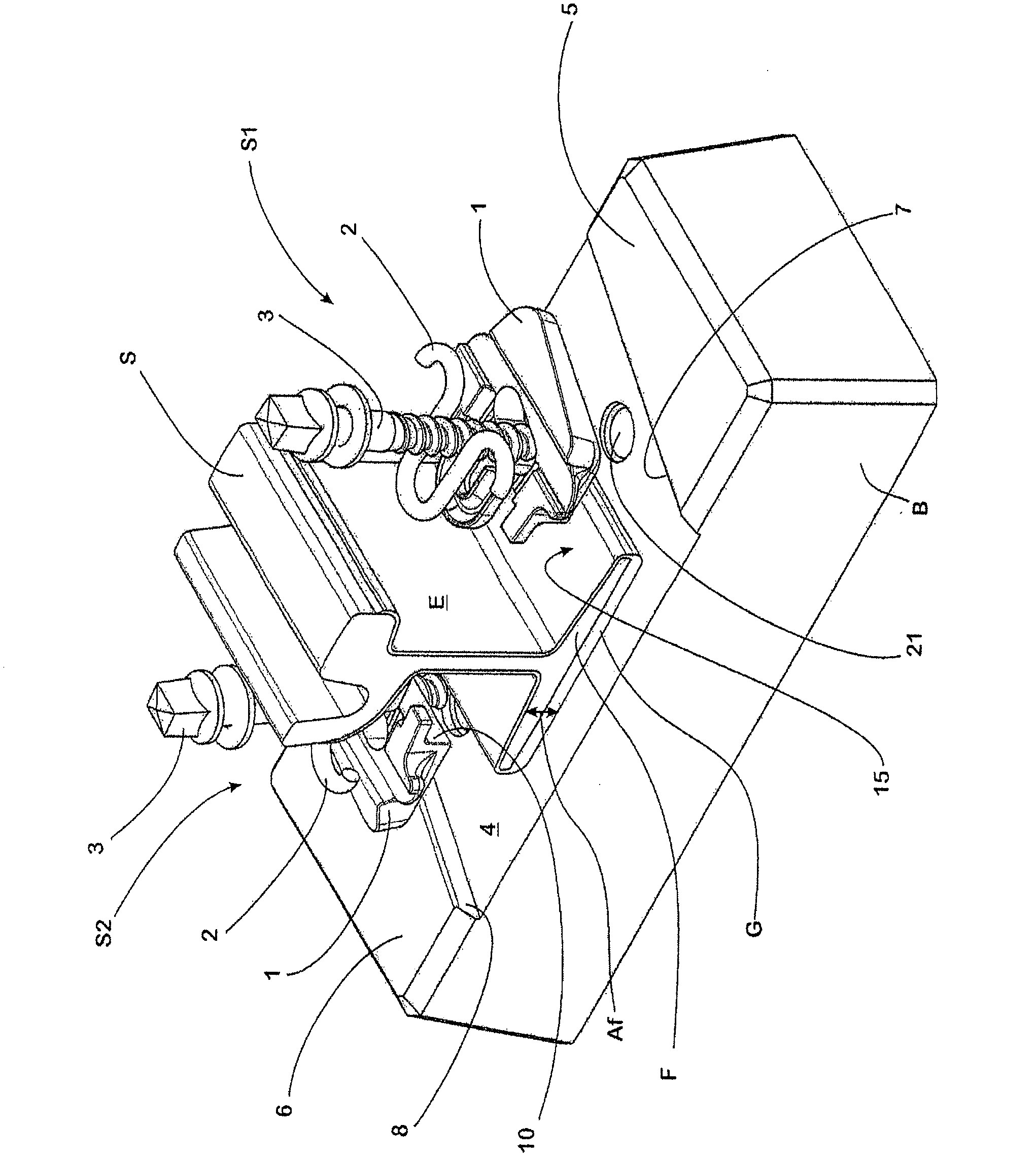

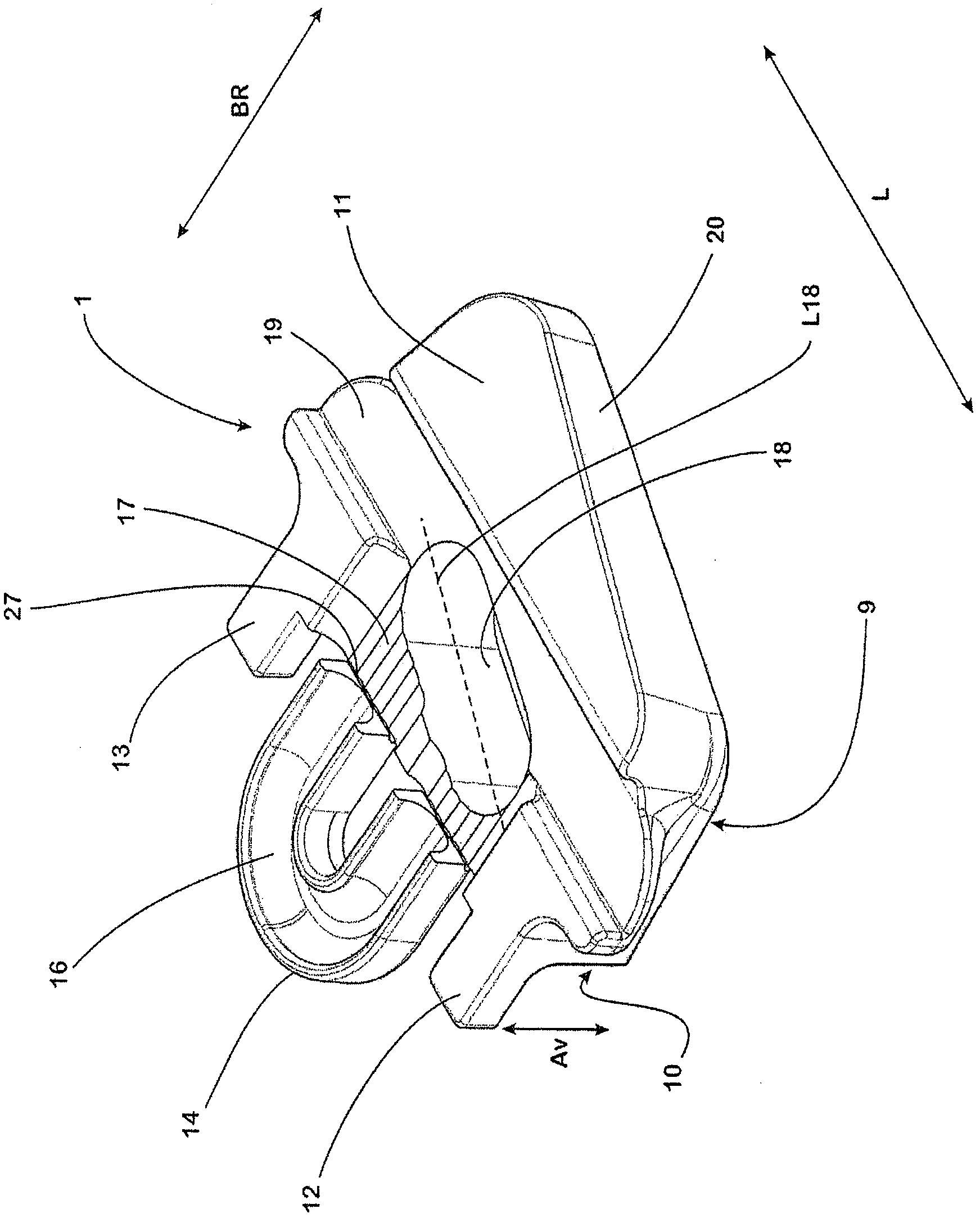

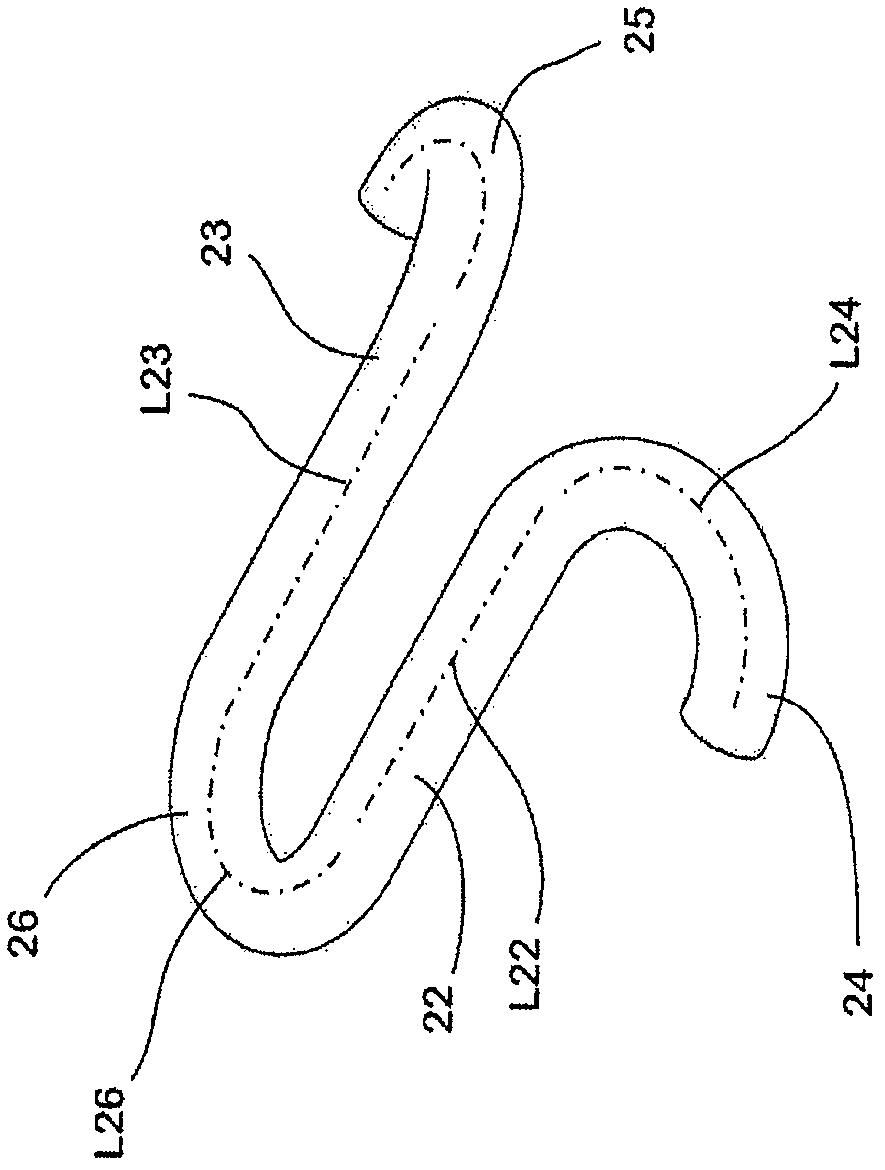

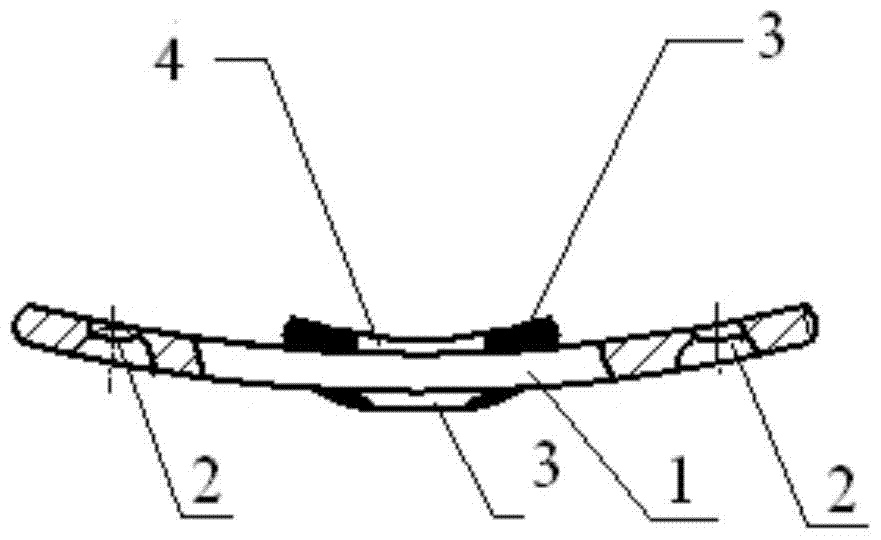

System for securing a rail and securing a rail

The invention relates to a system (S1, S2) for securing a rail (S) to a solid foundation (B), comprising a guide plate (1,30), a securing element (3) and a spring element (2). Said guide plate (1,30) comprises a bearing surface (10) on which the longitudinal side of the rail base (F) rests when in the mounted position. Said spring element (2) has a W or S shaped frame and comprises a section (22, 23, 26) which, when in the mounted state, protrudes so far over the rail base (F) that said rail base (F) is maintained elastically by said spring element (2) when it moves upwards, away from the solid foundation (B) in the vertical direction.

Owner:VOSSLOH WERKE GMBH

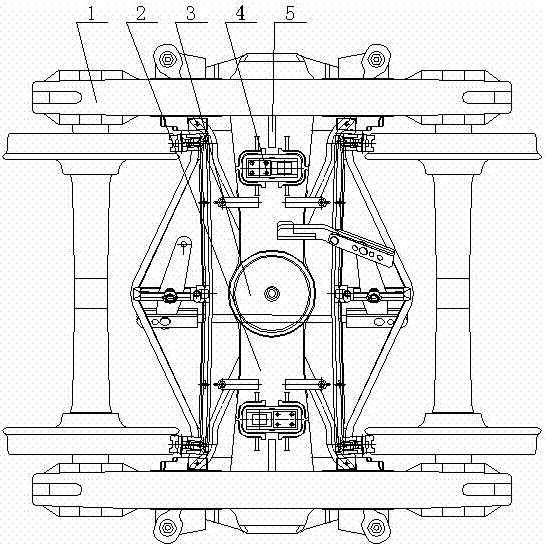

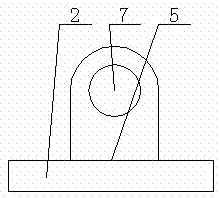

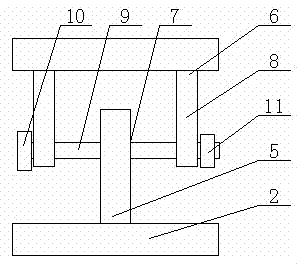

Anti-loosening steering frame of railway vehicle

InactiveCN103693060AReduced risk of looseningAvoid getting in the wayBogie-underframe connectionsBogieEngineering

The invention discloses an anti-loosening steering frame of a railway vehicle. The anti-loosening steering frame of the railway vehicle comprises a side frame, a swing bolster, a central pin and a limiting connection piece, wherein the central pin is arranged in the middle of the swing bolster; an elastic side bearing assembly is arranged between the central pin and the side frame; the lower end of the elastic side bearing assembly is arranged on the swing bolster; the lower end of the limiting connection piece is connected with the swing bolster; a joint of the lower end of the limiting connection piece and the swing bolster is positioned between the elastic side bearing assembly and the side frame; the upper end of the limiting connection piece is connected with a vehicle under-frame; the height difference and the horizontal distance between the upper end and the lower end of the limiting connection piece can be changed in a predetermined range. According to the anti-loosening steering frame of the railway vehicle, the safety of combination of the steering frame and the vehicle under-frame can be improved on the premise that free steering of the steering frame in an allowed range is not affected.

Owner:TONGLING SHENGWANG RAILWAY EQUIP

A self-reducing anterior anatomical plate for atlantoaxial dislocation

ActiveCN105213007BDislocation playedGood reset fixation effectInternal osteosythesisBone platesAtlantoaxial dislocationIliac screw

The invention discloses an atlantoaxial dislocation anterior anatomy template with an automatic reduction function. The atlantoaxial dislocation anterior anatomy template comprises an atlas part, an axis part and a connecting part. The atlas part is in an arc shape, and symmetrical screw holes are designed in the two sides of the atlas part. The axis part is located below the back of the atlas part and matched with the front structure of the body of the axis, five screw holes are designed in the axis part, four screw holes are symmetrically located in the two sides, and the other screw hole is located in the middle and is an oblong sliding screw hole. The atlas part and the axis part are connected through the connecting part. A screw slides in the sliding screw hole, so that the atlantoaxial dislocation reduction effect is achieved; through screw fixing, the atlantoaxial reduction purpose is achieved, the form of the template is completely matched with the anatomic form of the atlas and the axis, a higher degree of fit is achieved, and the template is attractive in appearance and good in reduction effect.

Owner:THE SECOND AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

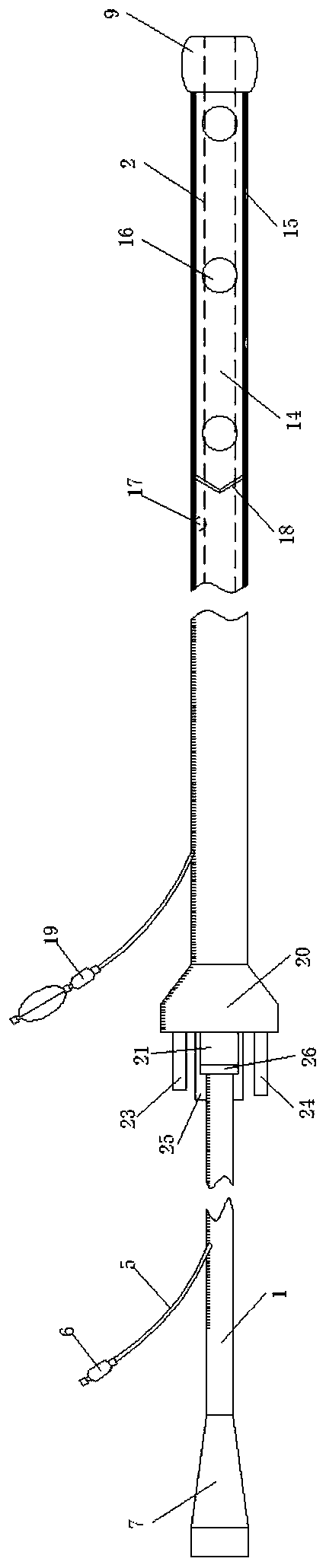

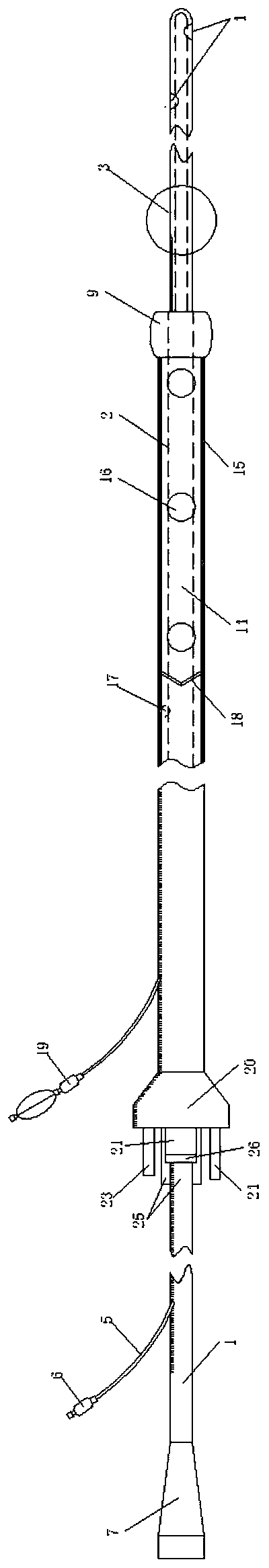

Multi-chamber slidable gastric tube

The invention discloses a multi-chamber slideable gastric tube. The multi-chamber slideable gastric tube includes a gastric tube and a phlegm suction catheter; a ball bag is fixedly connected to the periphery of the head of the gastric tube; the head of the gastric tube is provided with a gastric tube opening, a first inflation channel is provided in the gastric tube, the gas outlet of the inflation channel is communicated with the ball bag, a one-way valve is provided at the gas inlet of the first inflation channel, a gastric tube joint is provided at the end of the gastric tube, and a filterscreen is arranged in the inner chamber of the gastric tube joint; a gasbag is fixedly connected to the periphery of the head of the phlegm suction catheter, a gastric tube channel, a second inflation channel, a cleaning channel, an oxygen suction channel and a phlegm suction channel are arranged in the phlegm suction catheter, the head of the second inflation channel is communicated with the gasbag, the gastric tube slides in the gastric tube channel, the cleaning channel is communicated with the phlegm suction channel trough a cleaning hole, the oxygen suction channel is communicated with an oxygen suction hole, the phlegm suction channel is communicated with a phlegm suction hole, the cleaning hole is located at the downstream of the phlegm suction hole, a one-way valve is arranged inthe phlegm suction channel, the one-way valve is located between the phlegm suction hole and the cleaning hole, and a regulating valve is arranged at the end of the second inflation channel. The multi-chamber slideable gastric tube has the advantages of realization multi-time use by one-time intubation, loosening prevention, reduction of pipeline blockage, and prevention of suffocation.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Rotary discharging type cosmetic container

PendingCN107334251AImprove sealingPrevent leakagePackaging toiletriesPackaging cosmeticsEngineeringBung

The invention discloses a rotary discharging type cosmetic container. The cosmetic container comprises a container body, a coating assembly and a casing cover arranged outside the coating cover in a sleeving mode, the coating assembly comprises a plug, a valve element sleeve and a valve element, the plug is closely inserted into an opening of a container body, the valve element sleeve is arranged inside the container body, one axis side of the valve element sleeve is movably connected into one axis side of the plug in a clamped mode, and a first liquid outlet through hole is formed in the valve element sleeve in a run-through mode; the valve element is provided with a valve element body, one axial end of the valve element body is open, the other axial end of the valve element body is closed, a discharge head is connected to one axial end of the valve element body, the other axial end of the valve element body is movably inserted into the valve element sleeve after penetrating through the plug, and a second liquid outlet through hole is formed in the valve element body in a run-through mode; when the casing cover rotates relative to the container body, the casing cover can drive the valve element to rotate, and the first liquid outlet through hole and the second liquid outlet through hole can be overlapped to be communicated or staggered to be not communicated through rotation of the valve element; in this way, the sealing property of cosmetics in the carrying process can be improved, and the leakage phenomenon is avoided.

Owner:SHYA HSIN PACKAGING IND CHINA

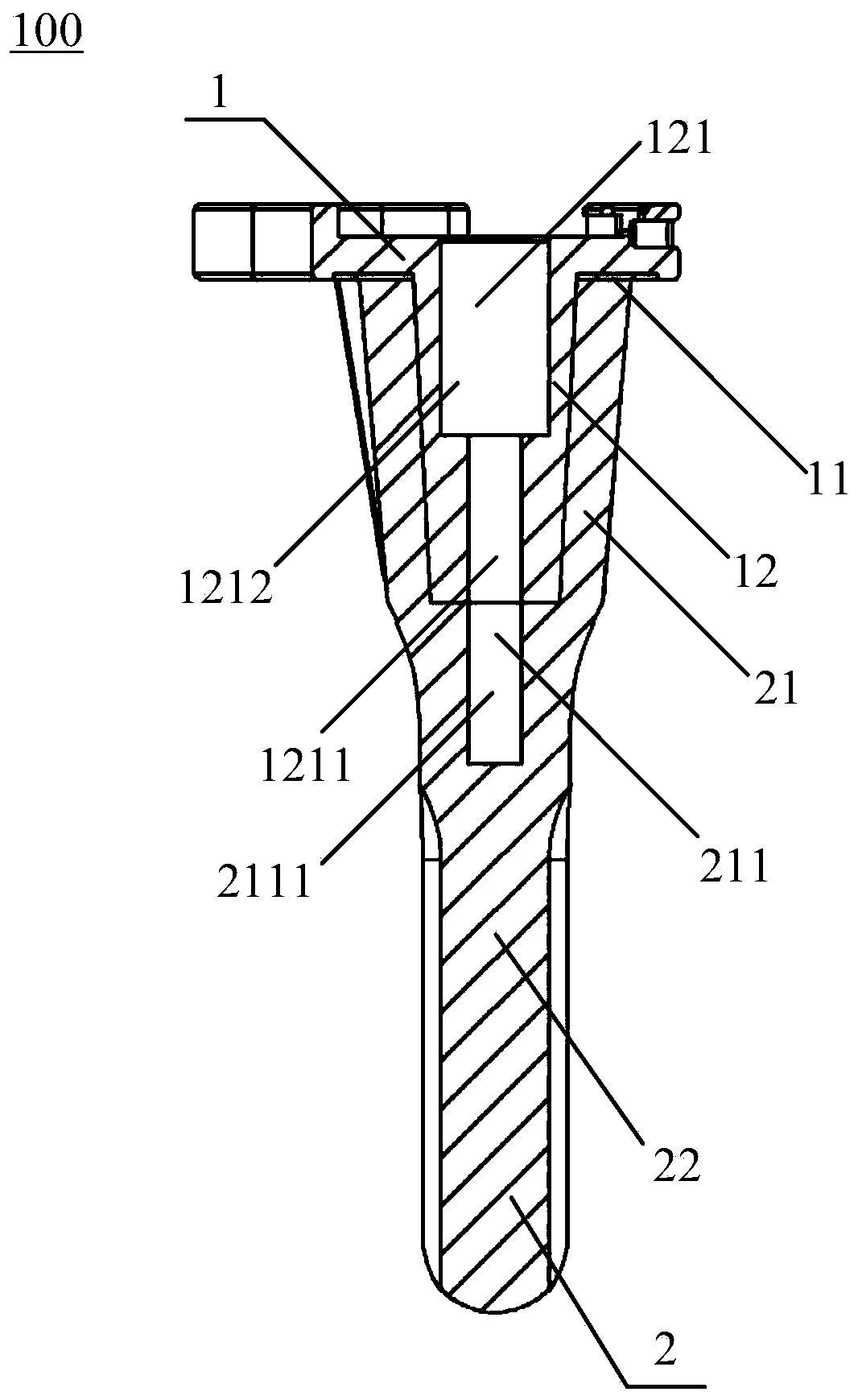

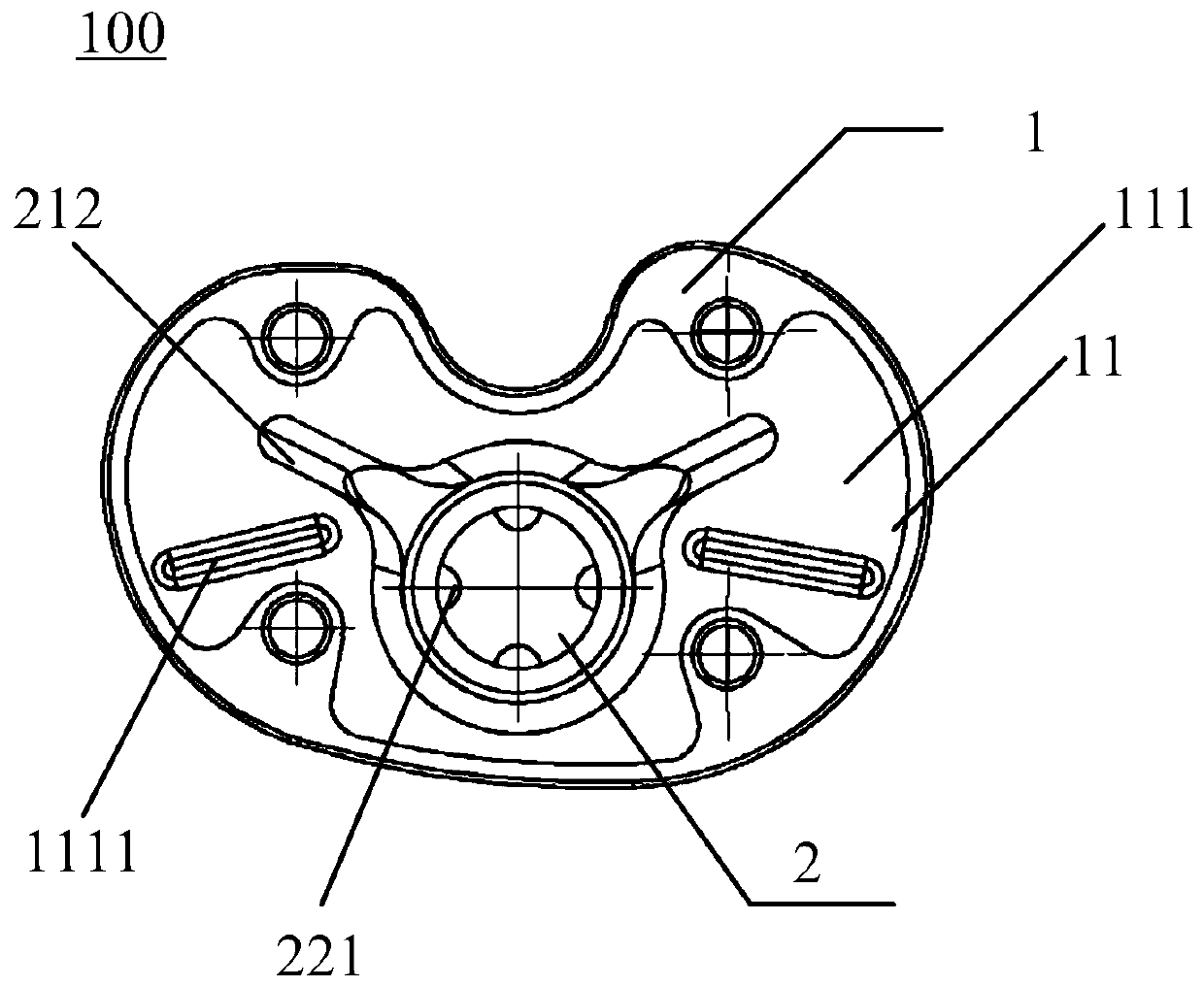

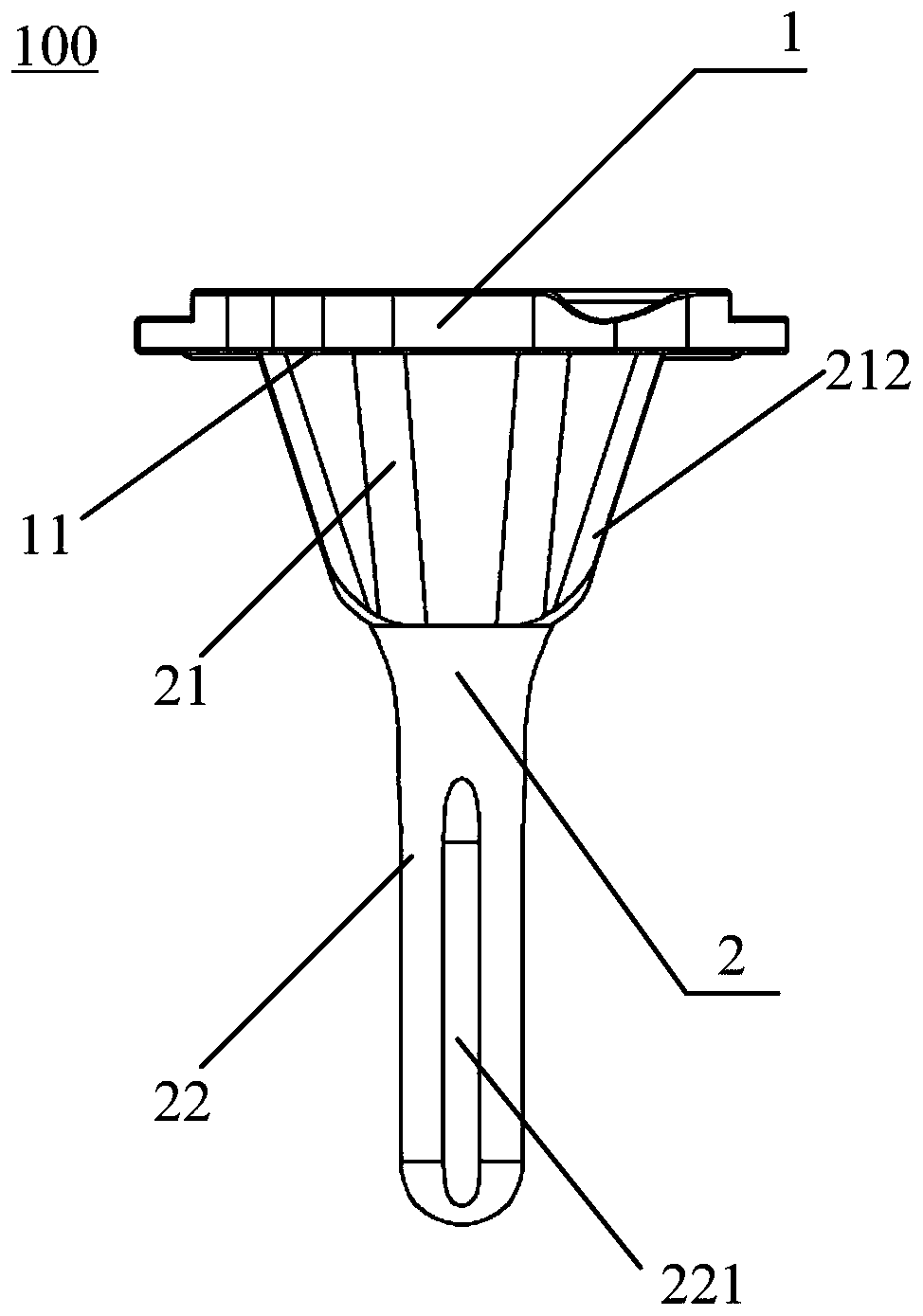

Tibial plateau assembly and knee joint prosthesis using tibial plateau assembly

PendingCN110786970AIncrease the lengthReduced risk of looseningJoint implantsKnee jointsKnee arthrodesis prosthesisAnatomy

The invention belongs to the field of medical apparatus, and discloses a tibial plateau assembly and a knee joint prosthesis using the tibial plateau assembly. The tibial plateau assembly includes a tibial plateau part and an extension part which is detachably connected with the tibial plateau part, wherein a connection column is formed on a first plane, which is used for being connected with a resected surface of a tibia, of the tibial plateau part and is perpendicular to the first plane; and the extension part includes a sleeving connection cylinder and an extension rod, wherein the sleevingconnection cylinder is used for being connected with the outer surface of the connection column in a sleeving mode, the extension rod is coaxially connected with the sleeving connection cylinder, andthe sleeving connection cylinder can rotate relative to the connection column and be fixed, so that rotation positions of the tibial plateau part relative to the extension part are adjusted and fixed. By adopting the tibial plateau assembly, loosening risks of a tibial plateau support can be effectively reduced, and meanwhile the universality of the tibial plateau support is enhanced.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

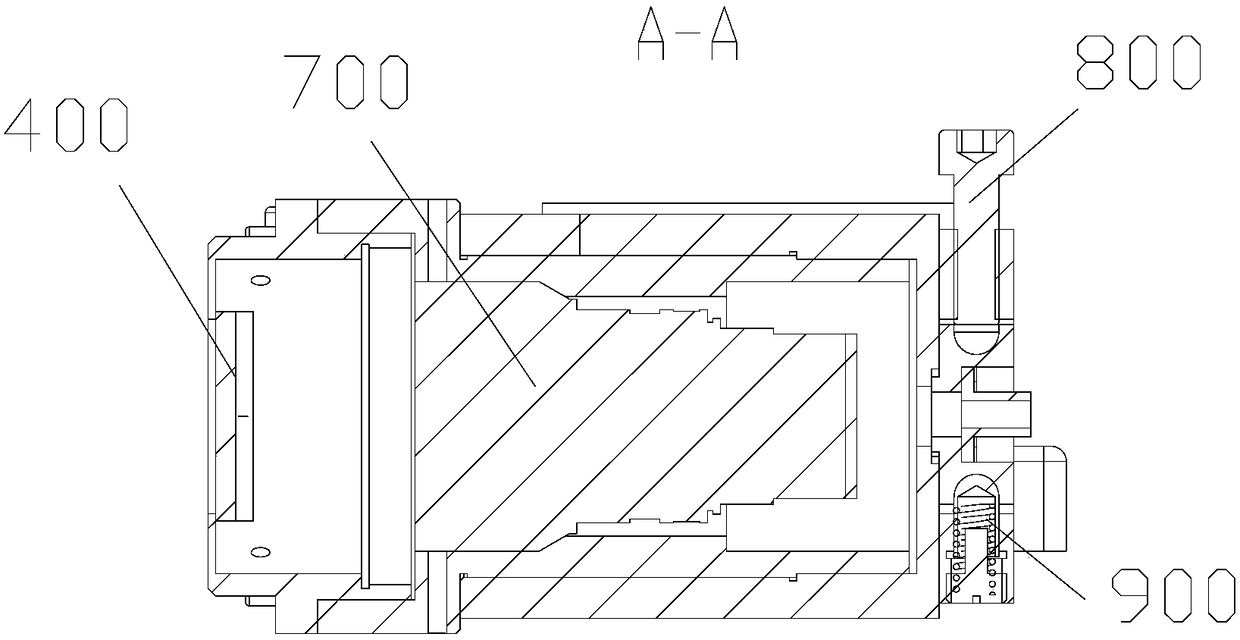

Linear light source and line scanning camera colinear adjusting device

The invention provides a linear light source and line scanning camera colinear adjusting device, comprising a linear light source and a line-scan digital camera, wherein the linear light source comprises a fixed mounting plate, a light barrel main body locked on the fixed mounting plate by a locking screw, a laser inlet movably arranged at one side of the light barrel main body, and a light barrellens set shell; the light barrel main body and the light barrel lens set shell adjust the relative positions of a lens set and the laser inlet by a thread pair, a condensing lens set is arranged in the light barrel set shell, and the light barrel lens set shell is fixed on the light barrel main body by a light barrel lens set fixing ring; a linear light source generator mounting seat is arrangedat one side of the light barrel lens set shell, a linear light source generator is arranged on the linear light source generator mounting seat, and a linear light source generator adjusting module isarranged at one side of the linear light source generator. According to the invention, a section where the light source is located can be rapidly and accurately superposed with a section where a line-scan digital camera chip is located.

Owner:亿新(北京)科技有限公司

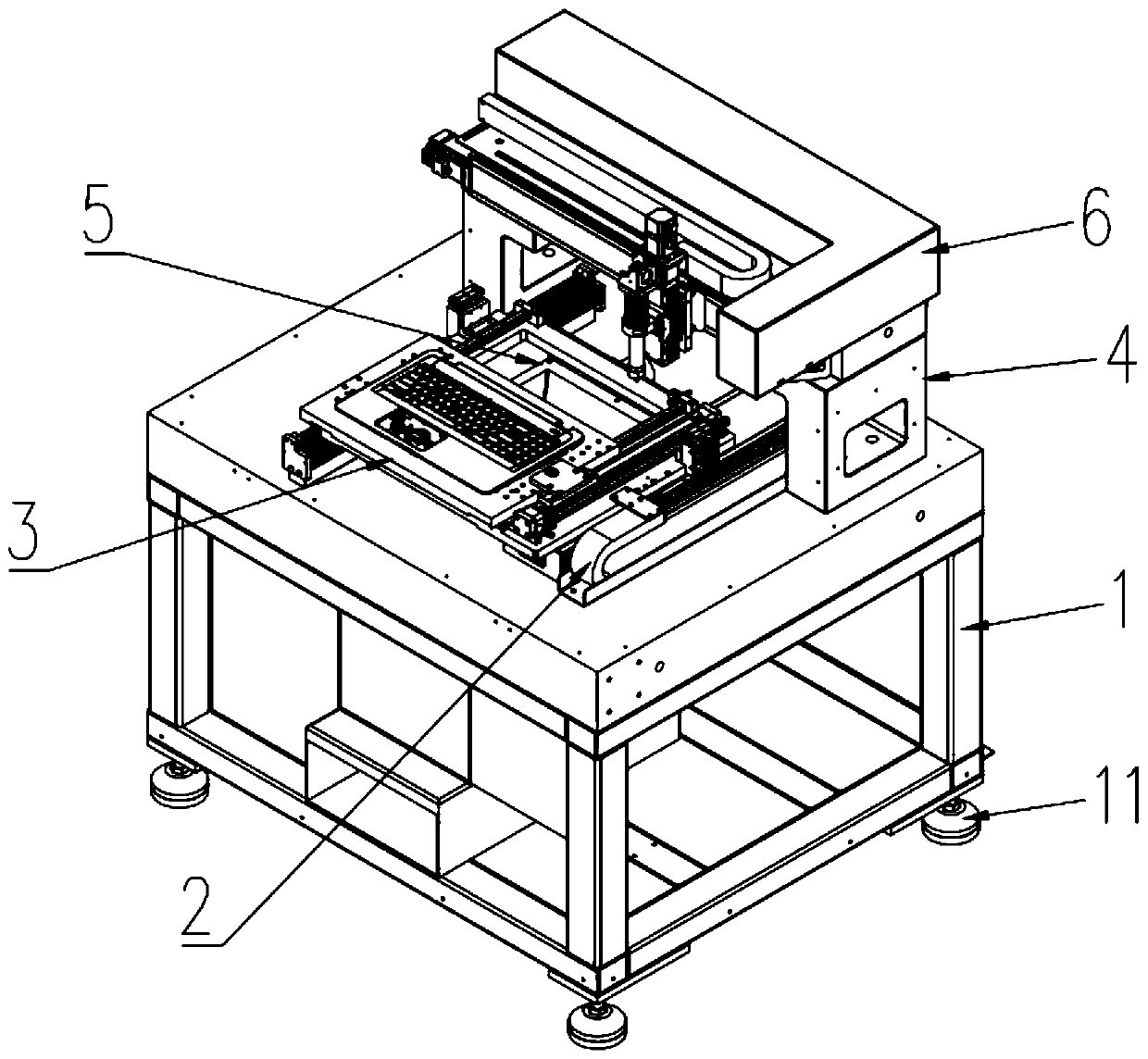

Full-automatic nonmetal laser machining equipment

PendingCN111230332AWith modular assemblyCompact structureWelding/cutting auxillary devicesAuxillary welding devicesLaser processingEngineering

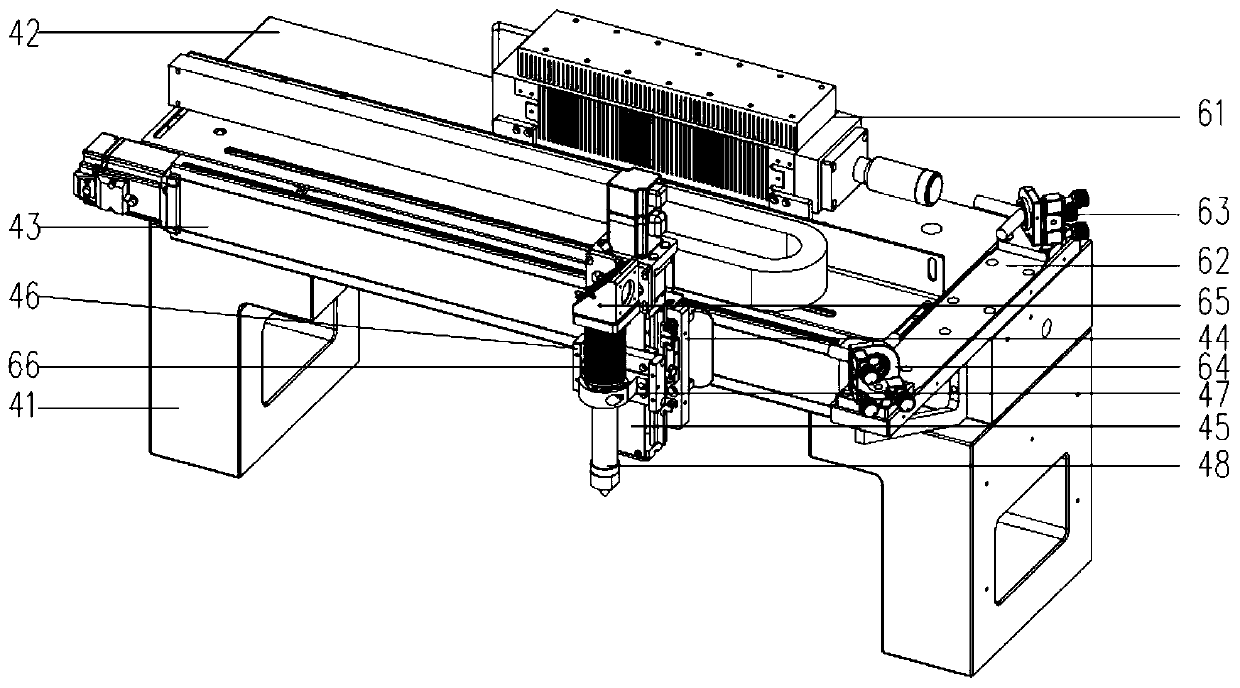

The invention discloses full-automatic nonmetal laser machining equipment. The equipment comprises an equipment support, wherein a workbench top is formed on the upper side face of the equipment support and is provided with a Y-axis module, a Y-orientation jig movement module and a laser machining module, the Y-orientation jig movement module comprises a jig supporting moving plate, jig guide rails, a positioning jig, a Y-orientation air cylinder and a Y-orientation air cylinder push plate, and the laser machining module comprises a fixed base, a laser device mounting plate, an X-axis module,an X-axis moving plate, a Z-axis module, a Z-axis moving plate, a laser cutting head fixing plate and a laser cutting head. The full-automatic nonmetal laser machining equipment is simple in structure, has comprehensive functions, and can be compatible with various feeding and discharging modes including manual labor and robots, and the machining mode of full-automatic unmanned guarding is achieved. Compared with traditional gantry double driving equipment, the full-automatic nonmetal laser machining equipment is simpler in structure, lower in cost and higher in stability; and moreover, the structure for conducting sealing protection on a laser device and two reflectors is adopted so that the maintenance on reflecting lenses and the laser device can be reduced, and the service life can beprolonged.

Owner:苏州锐涛光电科技有限公司

Punching tool

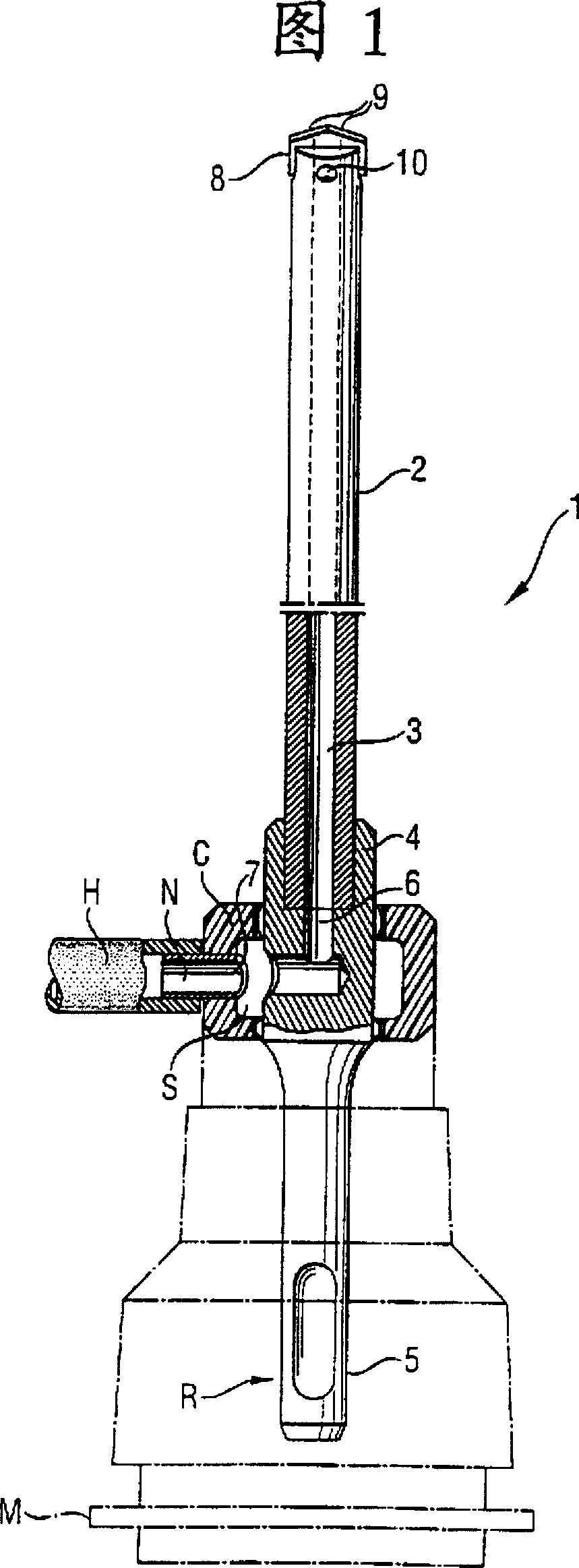

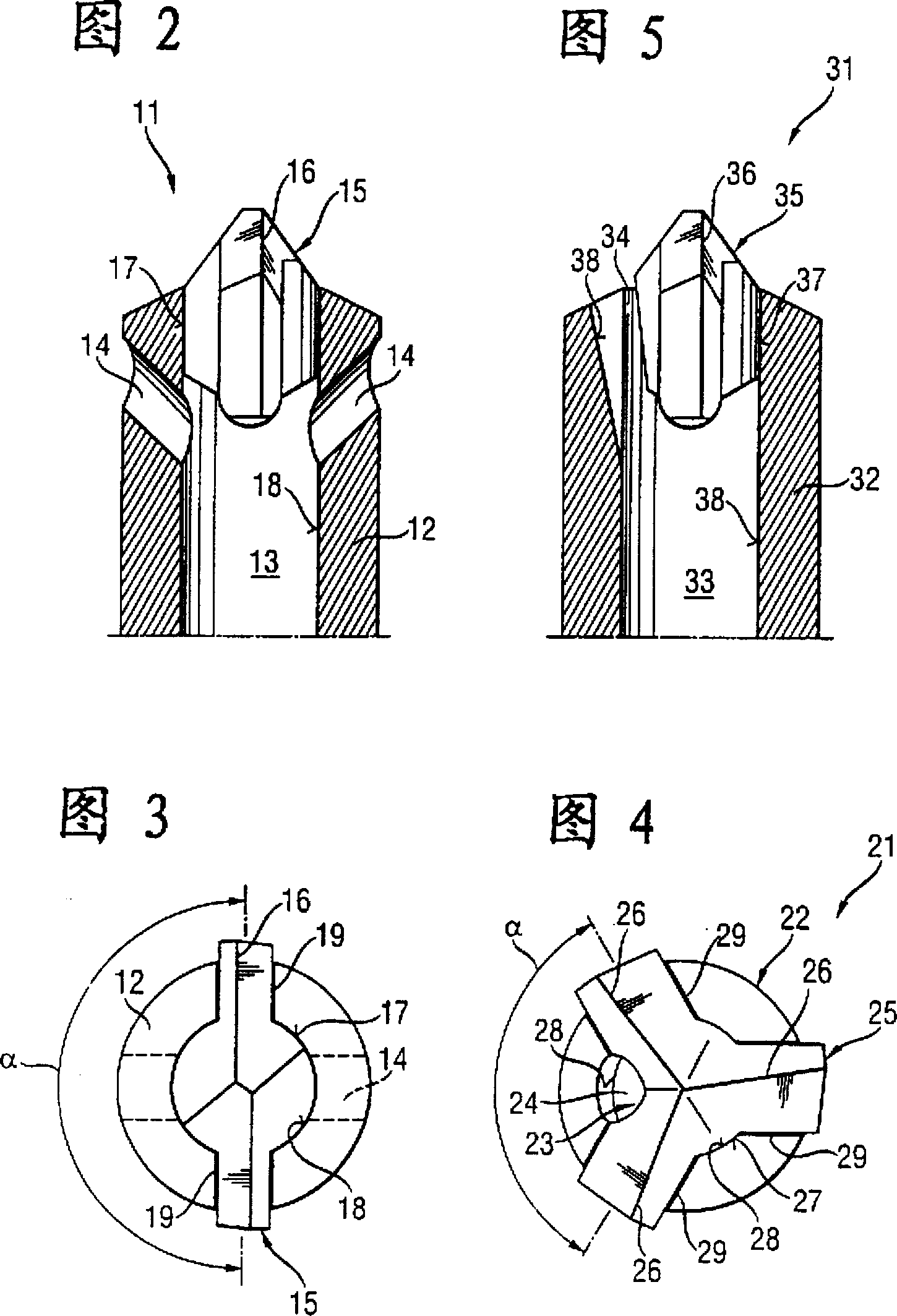

The invention relates to a drill tool for making a drill hole in a rock, a concrete, a wall material, etc, is provided with a hollow shaft (12) and a penetrated hole extending in the shaft direction communicates with opening parts (14) in both end regions in this shaft. In the shaft (12), the back end part is formed as a mounting end part for connecting with a drilling device and a drill head (15) supporting a cutter (16) and made of a hard material is supported on the front end part. The drill head is hooked on at least one slit extending approximately in the radial direction. The region of the drill head (15) embedded in the shaft (12) is strongly bonded with the shaft material under face contact over majority of the outer periphery.

Owner:HILTI AG

Tightening type mechanical hand and loading and unloading robot

The invention discloses a tightening type mechanical hand and a loading and unloading robot. The mechanical hand comprises at least three clamping jaws distributed in a polygon shape, the plurality ofclamping jaws can synchronously rotate forwards or reversely around longitudinally-extending shafts correspondingly, during forward rotation, a tail end opening defined by the plurality of clamping jaws is expanded or contracted, during reverse rotation, the change tendency of the tail end opening defined by the plurality of clamping jaws is opposite to that of the forward rotation, and the tailend opening defined by the plurality of clamping jaws is larger than the outer circumference of a to-be-clamped part when being in the largest state and smaller than the outer circumference of the to-be-clamped part when being in the smallest state. According to the scheme, the clamping jaws are in contact with the peripheral surface of the part, and therefore, the upper surface and the lower surface of the part cannot be damaged, meanwhile, the problems that pollution and damage occur again after cleaning can be solved, the wiping effect and quality of the part can be guaranteed, and when thespecial clamping jaw movement mode is applied to the parts with the same size, the clamping jaws can be shorter and smaller compared with clamping jaws with rotating shafts rotating horizontally, andthen the operation in a smaller space is facilitated.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com