Interbody fusion cage driver

An intervertebral fusion cage and driver technology, applied in joint implants, joint implants, spinal implants, etc., can solve the problems of increasing the risk of loosening of the cage, increasing the torque value, etc., and reducing the Risk of loosening, time cost saving, effect of shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

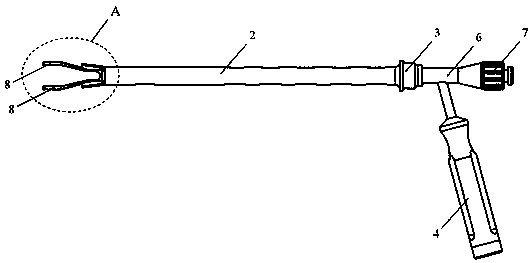

[0042] An intervertebral fusion device driver, the intervertebral fusion device driver comprising:

[0043] A clamping structure for clamping the intervertebral fusion device, including a connecting part and a clamping piece connected to one end of the connecting part;

[0044] A force-applying structure for applying force to the clamping part so that the clamping part is force-clamped;

[0045] The connection part is connected with the force applying structure.

[0046] The using method of described intervertebral fusion device injector, comprises the steps:

[0047] Position the clamping part on the intervertebral fusion device, the operator applies force to the force-applying structure, and then the force-applying structure applies force to the clamping part, the clamping part is tightened, clamps the intervertebral fusion device, and the intervertebral fusion device is After being placed in the desired position, the force applied to the force-applying structure is remove...

Embodiment approach

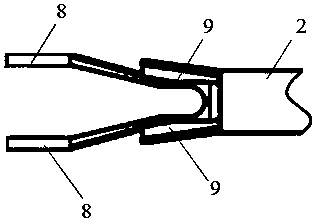

[0068] As another embodiment, the clamping member 8 can also be an open elastic piece;

[0069] As a preferred embodiment, the clamping member and the rod body are integrally structured;

[0070] The material of the clip and the clamping plate can be metal or plastic, which needs to have certain elasticity, can be tightened when stressed, and can restore the original shape after the external force is removed;

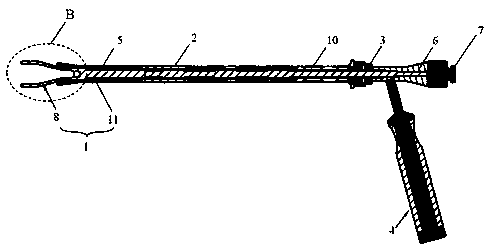

[0071] The clamping rod 1 and the sleeve 2 are slidingly fitted, and the elastic member is connected in the middle, so that the two clamping pieces 8 can be closed and opened after the structure is stressed;

[0072] The intervertebral fusion driver also includes a stop nut 3, a positioning part 6, and a tail cap 7 that are arranged on the other end of the rod body 11, and the distance between the tail cap 7 and the clamping member 8 is relatively long;

[0073] The limit nut 3 is threadedly connected with the sleeve pipe 2, and both the limit nut 3 and the sleeve pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com