Fluid interconnection suspension fork system realizing multiple functions

A suspension system and multi-functional technology, applied in the interconnection system, suspension, elastic suspension, etc., can solve the problems of easy damage, rollover, front and rear pitching, etc., to achieve sensitive and fast functions, quick response, and improved comfort performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

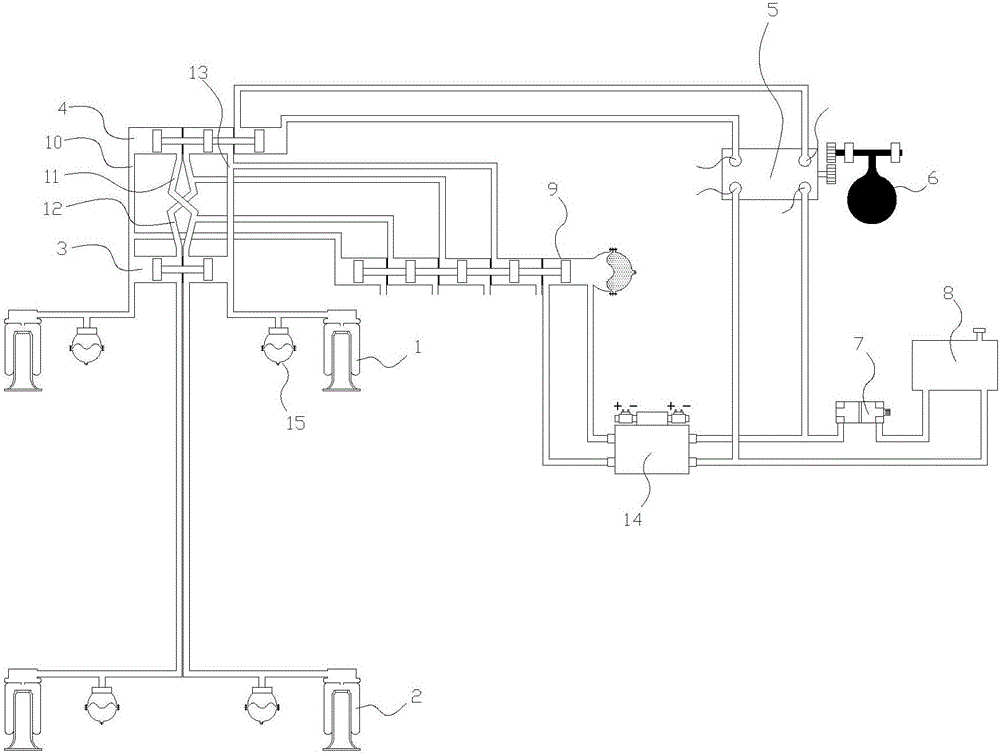

[0035] Such as figure 1 shown

[0036] A multifunctional fluid interconnected suspension system, including a buffer mechanism and a control cross lift converter 3, the buffer mechanism includes a front buffer mechanism 1 and a rear buffer mechanism 2, the front buffer mechanism 1 and the rear buffer mechanism 2 are respectively arranged on the On the upper side of the front wheel and the rear wheel, the front buffer mechanism 1 and the rear buffer mechanism 2 are respectively provided with interfaces;

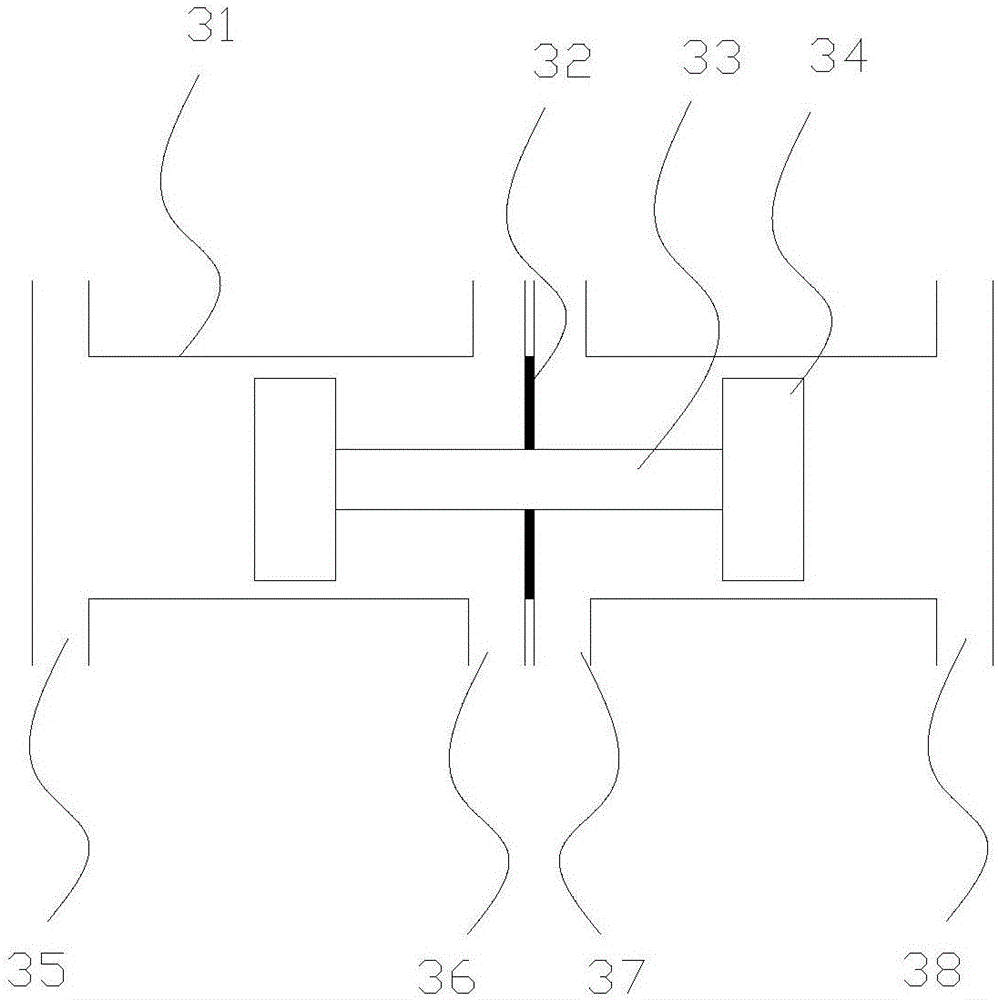

[0037] Such as figure 2 As shown, the control cross lift converter 3 includes a cylinder 31, a partition 32, a piston rod 33 and a piston 34, the partition 32 is fixedly arranged at the inner middle position of the cylinder 31, and the piston rod 33 slides through the partition 32 , the piston 34 is respectively fixedly arranged at the two ends of the piston rod 33, between the piston 34 and the front end of the cylinder 31, between the piston 34 and the partition 32, and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com