System for securing a rail and securing a rail

A technology of fixing device and track, applied in the field of system for fixing track and track fixing device, can solve problems such as loosening of fixing screws, and achieve the effect of convenient number of components and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

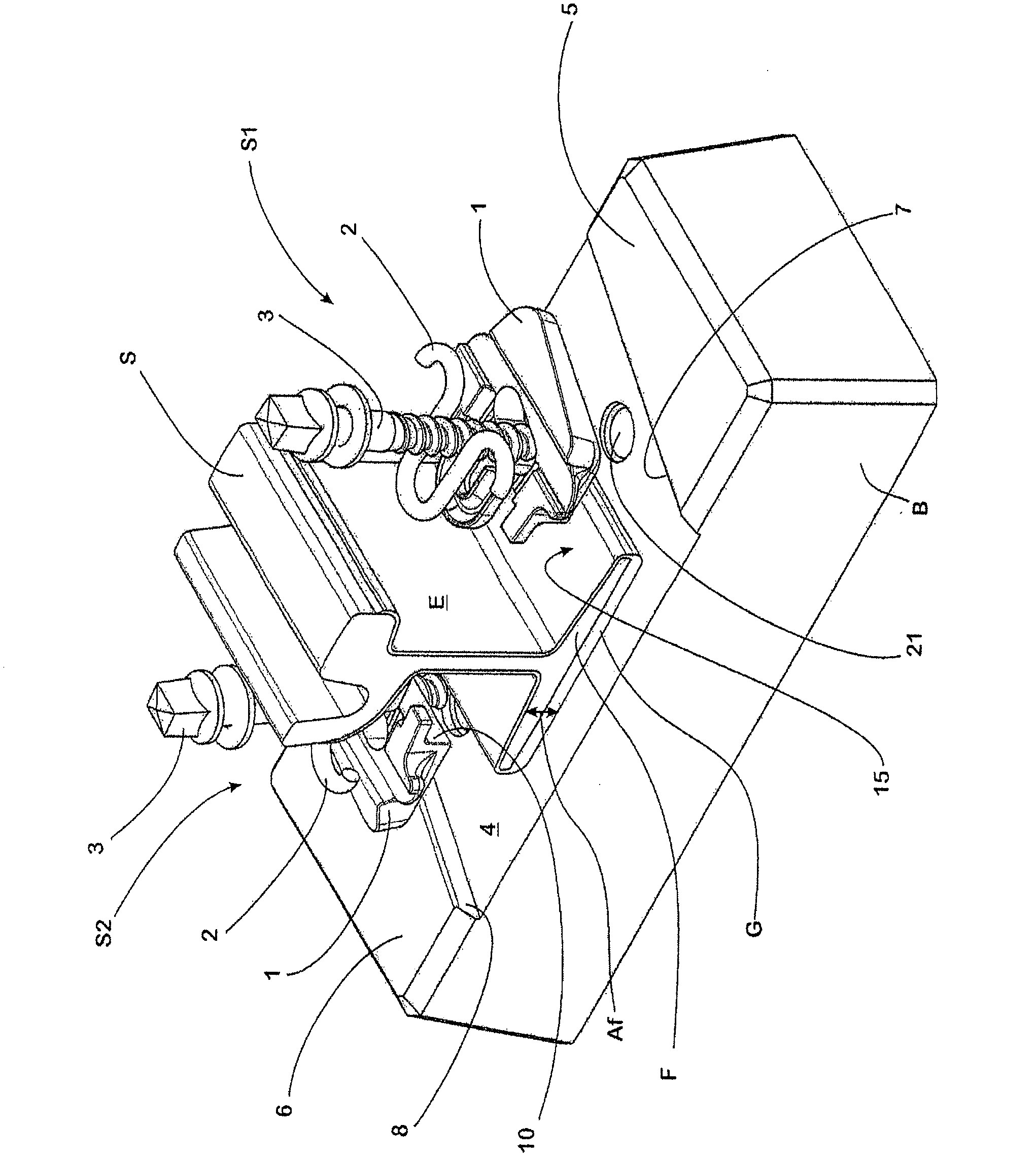

[0085] In order to fix the track S formed as a grooved track on the fixed base formed by the concrete sleeper B, it is realized by using two systems S1, S2 formed in this way, which respectively comprise the guide plate 1, the spring part 2 and the Clamping screw 3 for tight parts.

[0086] A planar ground contact surface 4 is formed in the concrete sleeper B, the long sides of which abut against the long sides of the sleeper B, while the wide sides of the contact surface are each delimited by a shoulder 5 , 6 . The supporting surfaces 7 , 8 of the shoulders 5 , 6 , which correspond to the contact surface 4 and run parallel to each other, are arranged at acute angles to the long sides of the contact surface 4 , so that the contact surface 4 has a parallelogram shape in plan view.

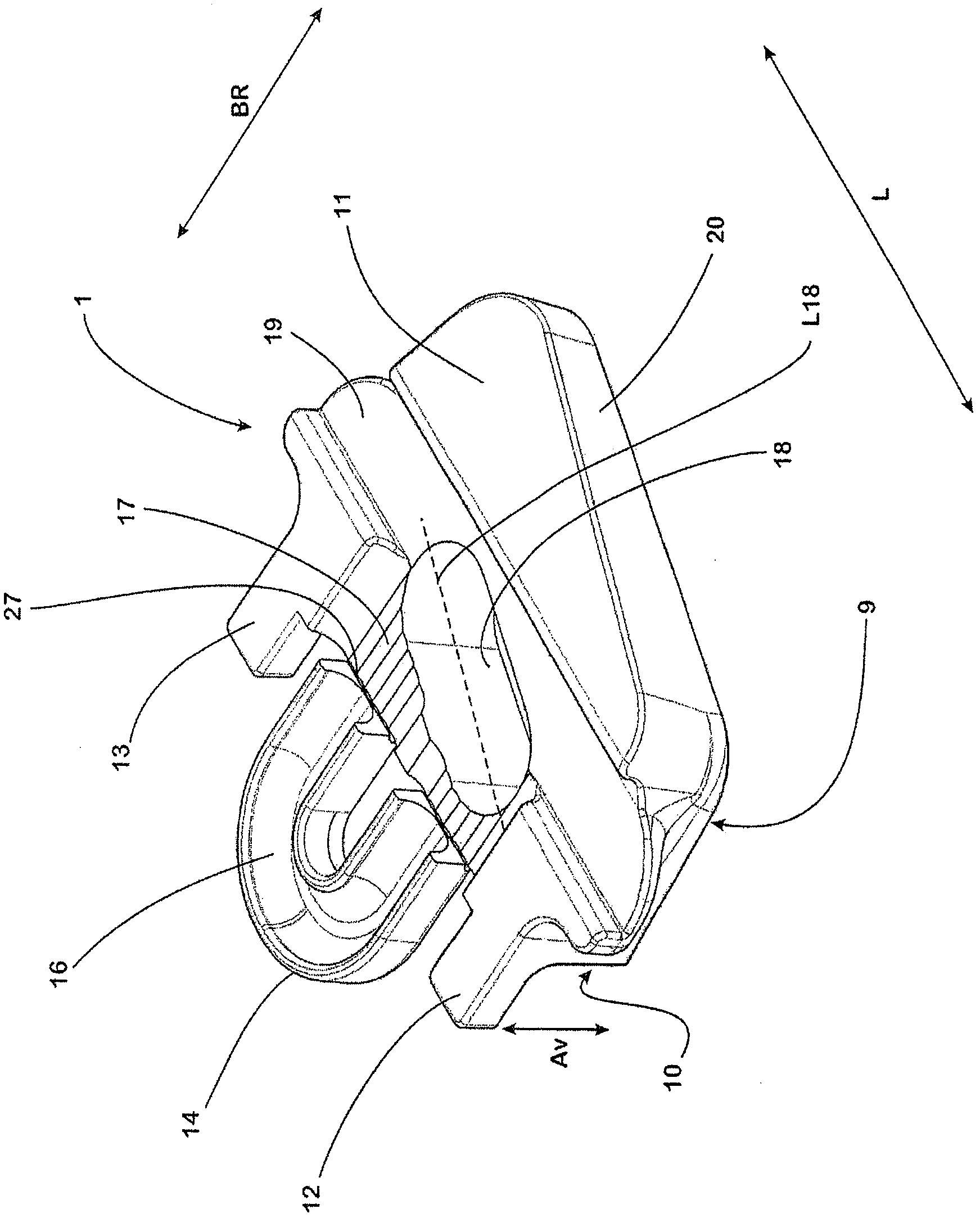

[0087] The guide plates 1 are made of non-conductive, for example fiber-reinforced plastic, and each have a support surface 9 on their undersides, with which the guide plates rest on the contact sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com