Pipeline rotary connector, cannon barrel direction adjusting mechanism and water cannon

A rotary connector and direction adjustment technology, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, weapon accessories, etc., can solve the problems that the rigid barrel cannot adjust the direction freely, and the elevation angle of the barrel cannot be adjusted, so as to reduce the sealing Sexual problems and the risk of screw loosening, improved life, and enhanced firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

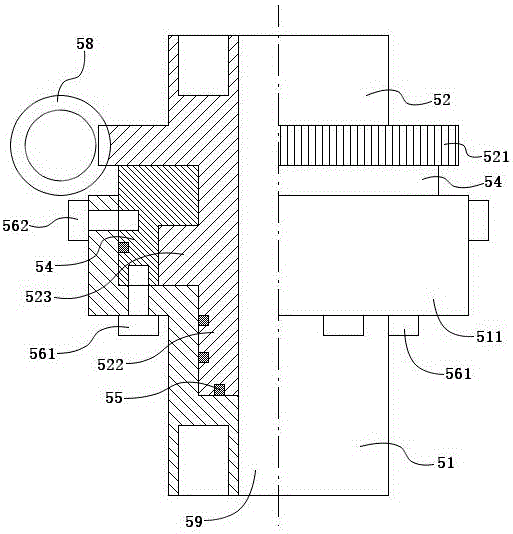

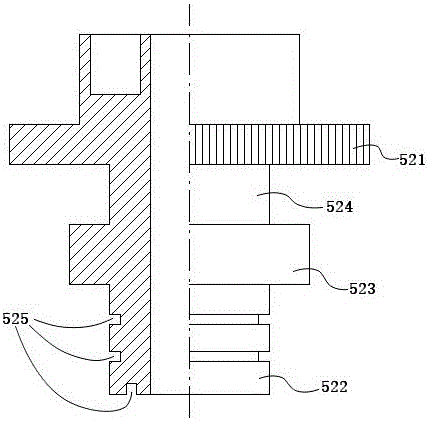

[0032] This embodiment is a pipe rotary connector, such as figure 1 , 2 , 3 and 4, including female joint 51, male joint 52, ring cover 54, worm rod 58 and motor. The female joint 51 and the male joint 52 are clamped together by a ring cover 54 , and a lumen 59 is provided inside. The female joint 51 and the male joint 52 can rotate around the axis of the lumen 59 .

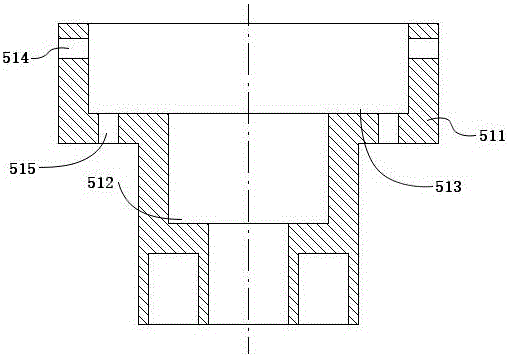

[0033] The female joint 51 is used to connect the fixed pipe, is installed at the end of the fixed pipe, and is provided with a first bayonet 512 and a second bayonet 513 . The first bayonet 512 and the second bayonet 513 have a cylindrical cavity, wherein the inner diameter of the first bayonet 512 is larger than the diameter of the lumen 59 . The inner diameter of the second bayonet 513 is larger than the inner diameter of the first bayonet 512 . The first bayonet 512 and the second bayonet 513 form a stepped bayonet structure. An opening is formed above the second bayonet opening 513 , and the opening is ...

Embodiment 2

[0042] This embodiment is a water cannon used for fire fighting or on a ship. The water cannon is provided with a barrel direction adjustment mechanism, and the barrel direction adjustment mechanism is realized by the pipe rotary connector in Embodiment 1. The water cannon is Figure 6 As shown, it includes a water cannon tank 1 , an air storage tank 41 , an air compressor 42 , a water storage tank 3 , a gun barrel 21 and a gun head 22 . The water cannon tank 1 is used to place the water that becomes the water cannon after launching, and is vertically installed on the ground or the base by the support frame 11. The air storage tank 41 is used for storing high-pressure compressed air and is connected with an air compressor 42 . The air compressor 42 compresses the air in the atmosphere to become high-pressure compressed air, which is sent into the air storage tank 41 through a pipeline. The air storage tank 41 is connected with the water cannon tank 1 through the solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com