Acrylic compound bone cement with partial degradation function and preparation method of acrylic compound bone cement with partial degradation function

An acrylic and bone cement technology, used in medical science, prosthesis, etc., can solve the problems of lack of interfacial activity of PMMA bone cement, inability to form a stable and firm interface, poor polymer biocompatibility, etc., to reduce fracture or regression. change risk, reduce the risk of loosening, reduce the effect of stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of bone cement powder and liquid 19.6 parts by weight of polymethyl methacrylate powder (average particle diameter: 50 μm, average molecular weight 150000, particle shape: spherical, purchased from (AlfaAesar (China) Chemical Co., Ltd. .)) and 0.4 parts by weight of benzoyl peroxide (purchased from Jiangsu Qiangsheng Functional Chemical Co., Ltd.) were mixed uniformly, thus providing a mixed powder component.

[0042] On the other hand, 0.109 g of N,N-dimethyl-p-toluidine (purchased from AlfaAesar (China) Chemical Co., Ltd.) was added to 9.4 parts by weight of methyl methacrylate (purchased from Sinopharm Chemical Reagent Co., Ltd.) and mixed Homogeneous, thereby providing a liquid component.

[0043] Then, the thus obtained mixed powder component and mixed liquid component were used to prepare a bone cement composition kit comprising a first component consisting of 20 g of the mixed component and a second set consisting of 9.509 g of the mixed liqui...

Embodiment 2

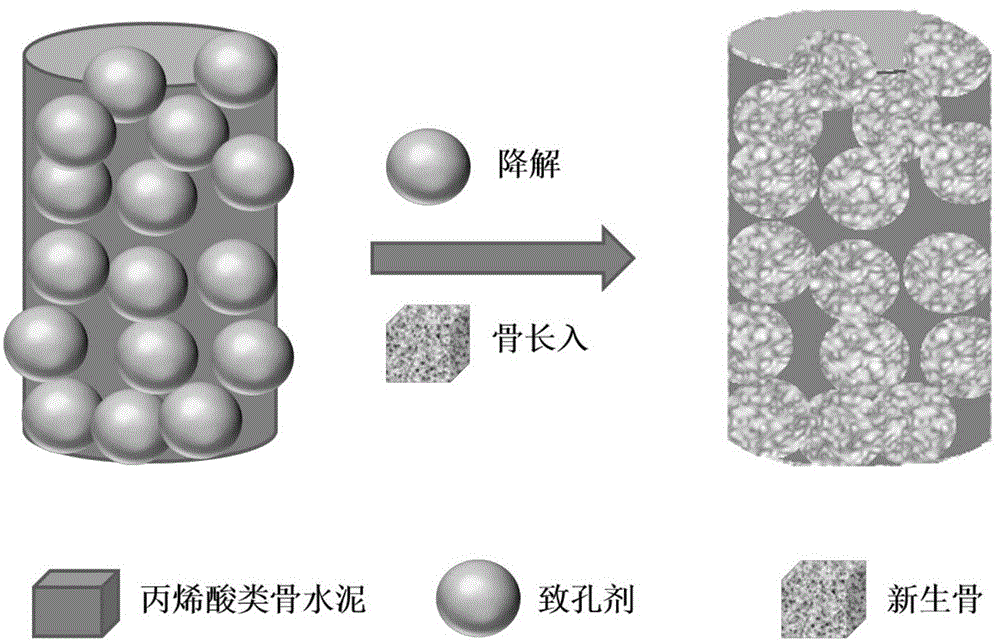

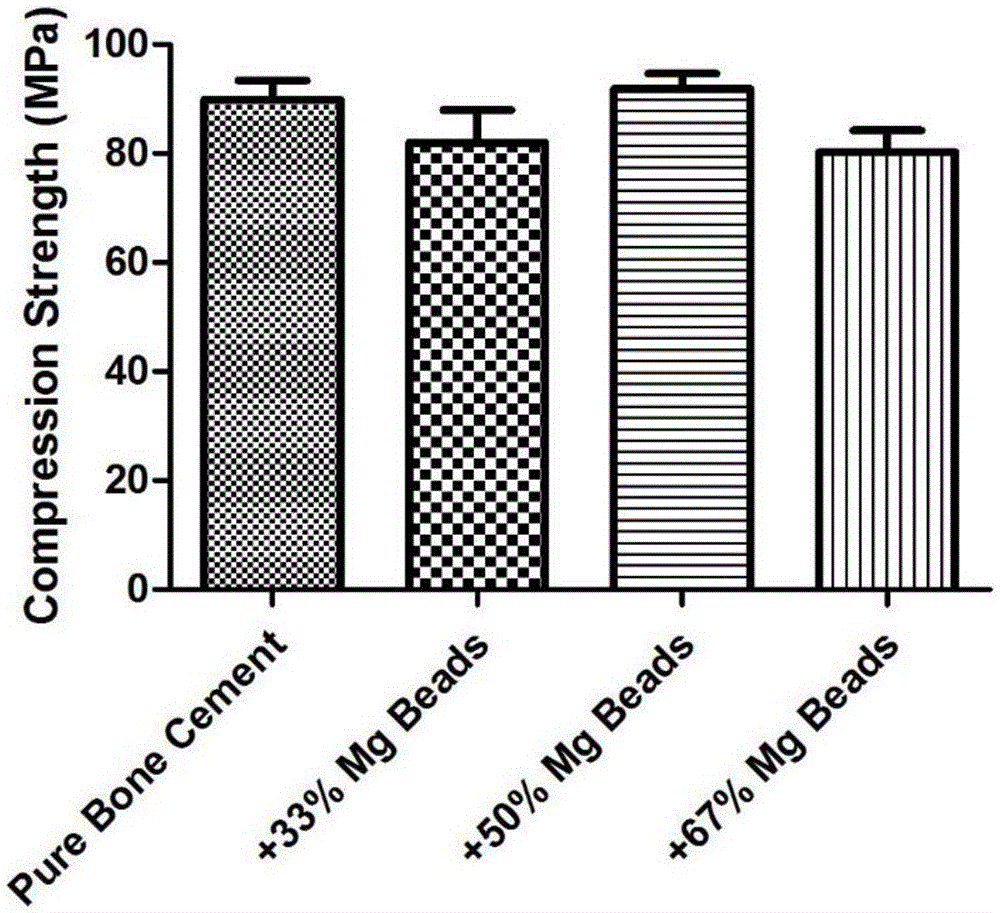

[0044] Embodiment 2 Magnesium ball / PMMA composite bone cement with partial degradation function and preparation method thereof

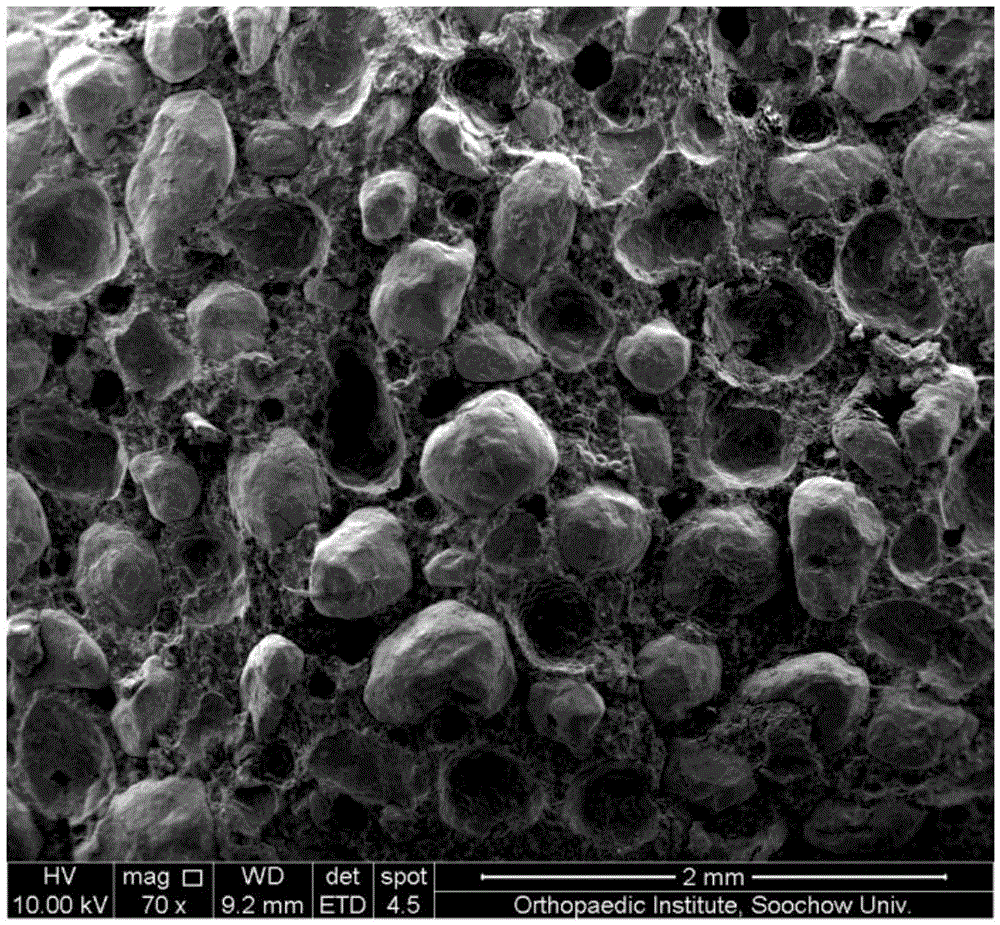

[0045] The third component in this bone cement is respectively 10g, 20g, 40g of magnesium balls (accounting for 33%, 50%, 67% of the total solid mass, purchased from AlfaAesar (China) Chemical Co., Ltd., with a particle size of 150-900 μm ) as a porogen.

[0046] The first component of the bone cement composition kit (mixed powder component: 20 g) was charged into a stirring container made of agate, followed by the second component of the bone cement kit (mixed liquid Component: 9.509g), stirred for 3 minutes to obtain the PMMA bone cement of the drawing stage. At this point, the third component is added to the PMMA bone cement, and fully stirred to obtain a magnesium ball / PMMA composite bone cement with a partially degradable function. The control group did not add the third component.

Embodiment 3

[0047] Example 3 Hydroxyapatite-coated magnesium ball / PMMA composite bone cement with partial degradation function and its preparation method

[0048] Magnesium spheres (purchased from AlfaAesar (China) Chemical Co., Ltd., with a particle size of 150-900 μm) were corroded with 1 mol / L hydrochloric acid for 5 minutes, taken out, and quickly cleaned in distilled water. Then put it in 0.5mol / L sodium hydroxide solution at a temperature of 100°C, take it out after 30 minutes, and clean it with distilled water. Prepare a 0.1mol / L calcium chloride solution and a 0.1mol / L dipotassium hydrogen phosphate solution, place the acid-base treated magnesium balls in the calcium chloride solution, and then slowly add an equal volume of dipotassium hydrogen phosphate Potassium solution, after stirring for 1 hour, take it out and wash it with distilled water. Finally, the pre-calcified magnesium spheres were immersed in 10 times the simulated body fluid for 2 hours to obtain hydroxyapatite-coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com