Mounting structure for hidden handle and mounting method thereof

A technology that hides the handle and installation structure. It is applied in the application of locks, building structures, vehicle locks, etc., and can solve the problems of difficult assembly, narrow space, and complex door structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

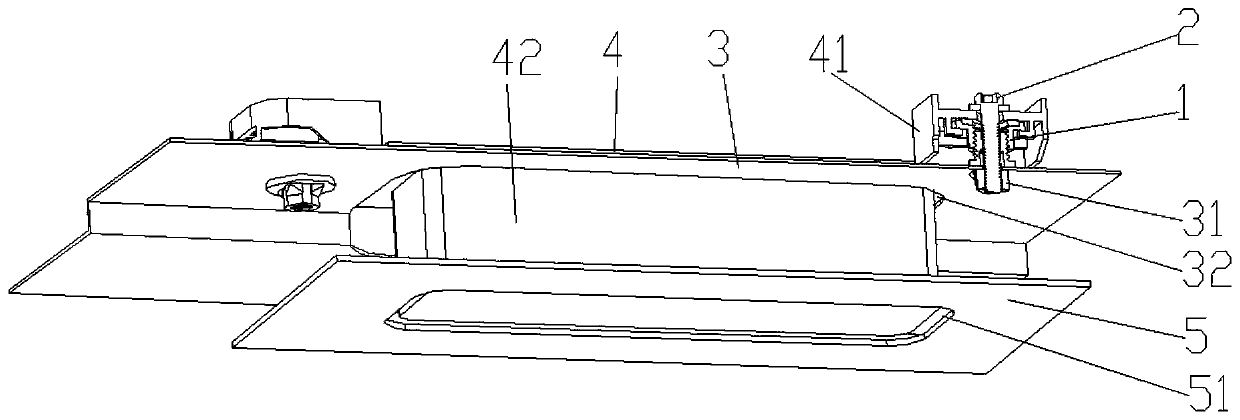

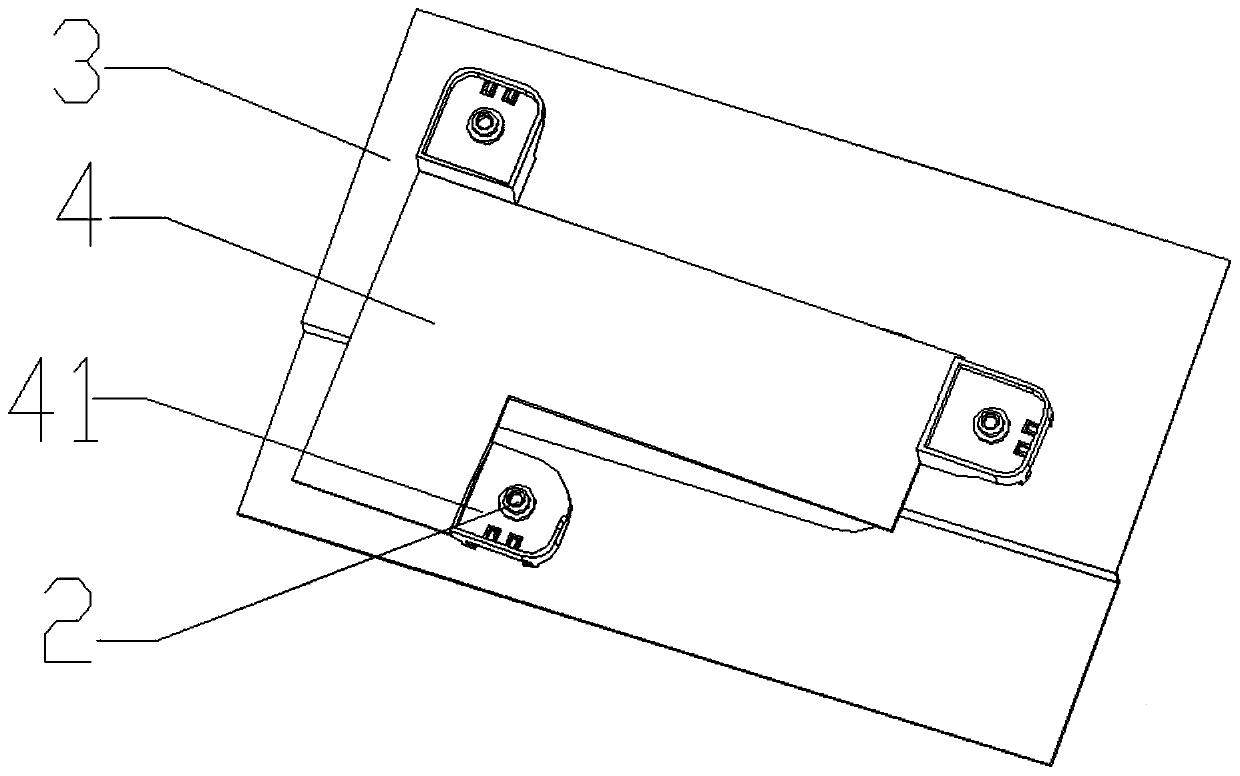

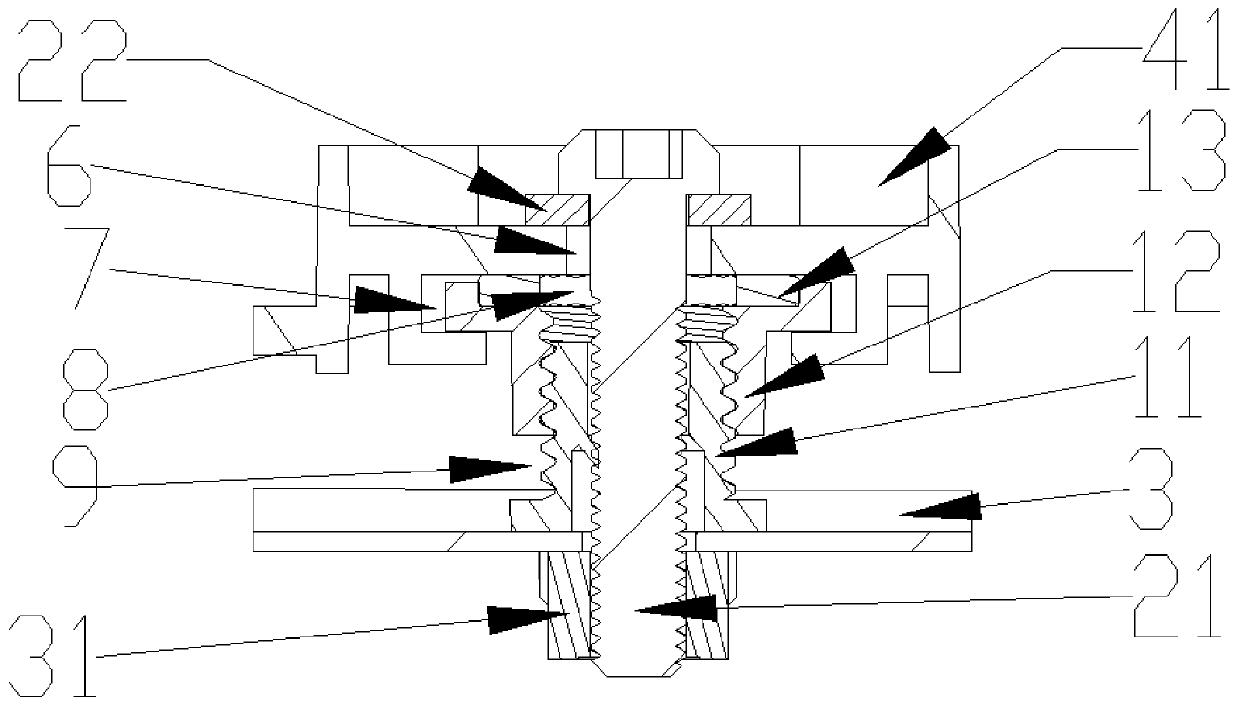

[0056] This embodiment provides an installation structure for hiding the handle, and its structure is detailed in the attached Figure 1-11Shown: including tolerance adjuster 1, bolt assembly 2 inner sheet metal 3 and concealed handle 4, said tolerance adjuster 1 includes locking plate 13 and thread group kit, said thread group kit includes positioning nut 12 and shrapnel adjustment screw Column 11, the bolt assembly 2 includes fastening bolts 21 and fixing gaskets 22, the hidden handle 4 is provided with a handle base positioning structure 41; the inner sheet metal 3 is provided with a first slot 32 and bolts Installation via holes, and the bottom end surface of the inner sheet metal 3 is welded with a fixed nut 31 with the same hole center as the bolt installation via hole, and the fastening bolt 21 passes through the fixed gasket 22 and the handle base positioning structure in turn. 41. Locking plate 13, positioning nut 12, shrapnel adjusting stud 11, bolt installation hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com