Rotary discharging type cosmetic container

A cosmetic container and spin-out technology, which is applied in cosmetic powder containers, cosmetic packaging, dressing containers, etc., can solve problems such as user property loss, cosmetic leakage, handbag pollution, etc., to meet the needs of use, easy to operate, The effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

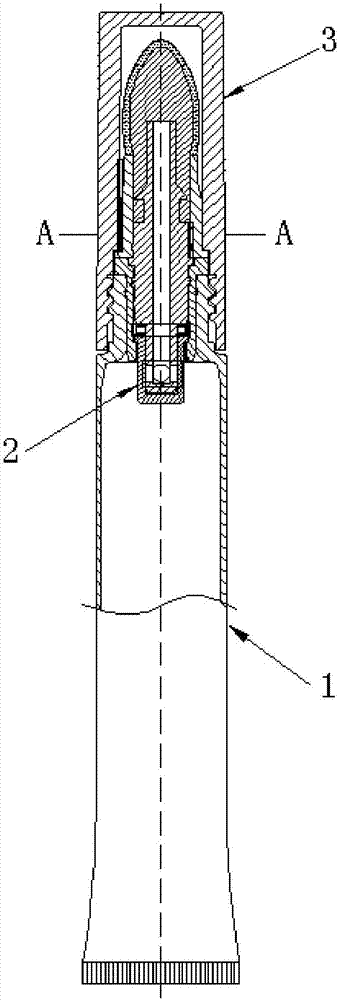

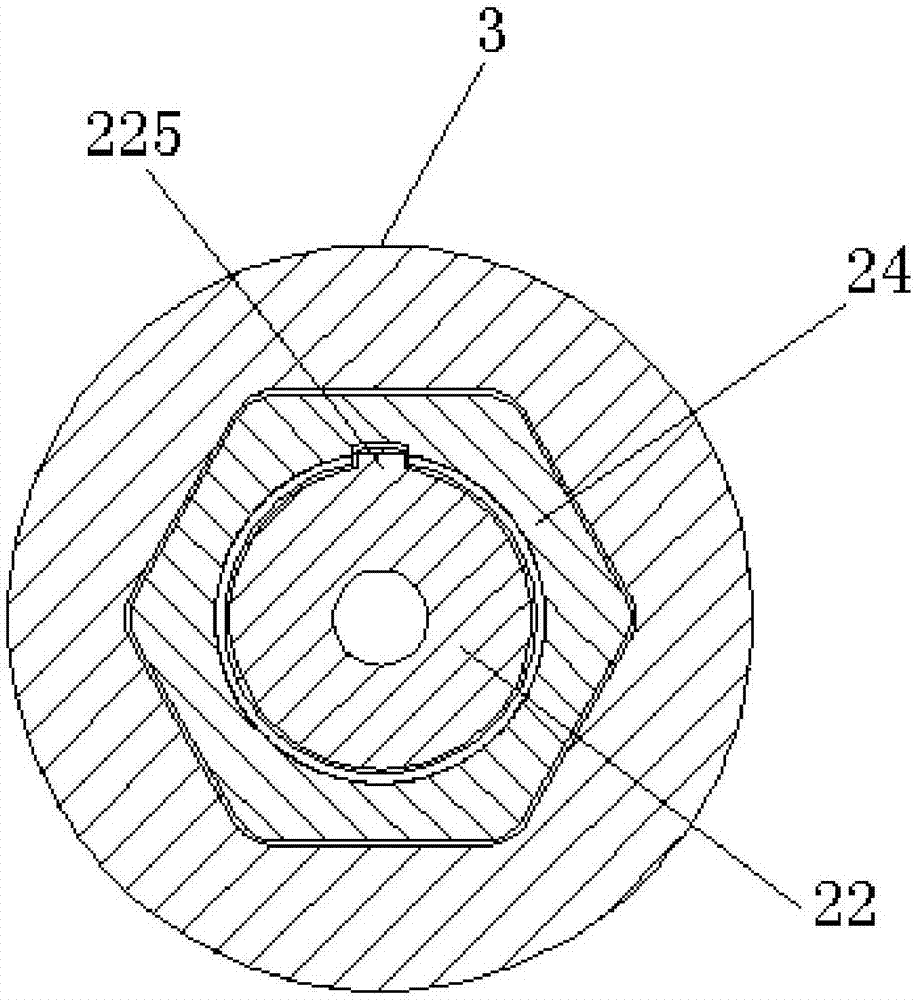

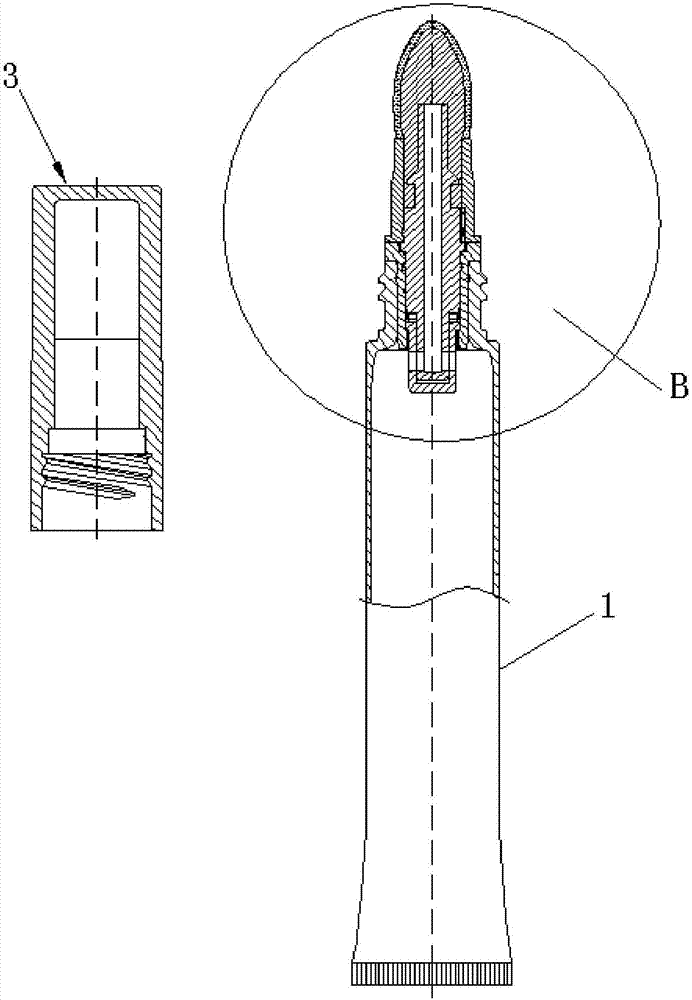

[0064] See attached figure 1 As shown, it is a schematic cross-sectional structure diagram of the first embodiment of the rotary discharge type cosmetic container of the present invention. The rotary discharge type cosmetic container includes a container body 1 for containing cosmetic liquid, a coating assembly 2 for drawing out the cosmetic liquid and applying it on the user's face, and a housing cover 3. One side of the coating component 2 is sealed and inserted into the opening 10 of the container body 1, the casing cover 3 is sleeved outside the coating component 2, and the casing cover 3 is also connected to the opening 10 In particular, the coating assembly 2 includes a plug 20, a spool sleeve 21 and a spool 22, see the attached Figure 4 As shown, the plug 20 is a sleeve-shaped structure with openings on both axial sides, and the plug 20 is tightly inserted into the opening 10; the valve core sleeve 21 is open on one side of the shaft and the other A hollow cylindrica...

Embodiment 2

[0080] See attached Figure 13 As shown, it is a schematic cross-sectional structure diagram of the second embodiment of the rotary discharge type cosmetic container of the present invention.

[0081] The structure of the rotary discharge type cosmetic container shown in embodiment 2 is basically the same as the rotary discharge type cosmetic container shown in embodiment 1, the main difference lies in the structure of the damping member. The structure of the damping member configured in Embodiment 2 is: on the outer wall of the valve core sleeve 21 and close to the position of the third overlapping edge 211, a ring-shaped fifth locking groove 214 is recessed, and another There is a sealing ring 25, the sealing ring 25 is embedded in the fifth clamping groove 214, and touches the inner side wall of the first overlapping edge 201 at the same time; wherein, the sealing ring 25 is the damping member (For details, please refer to the attached Figure 14 - attached Figure 16 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com