Preparation method of biopiezoelectric coating on titanium alloy surface

A titanium alloy and coating technology, which is applied in the field of preparation of bio-piezoelectric coatings on the surface of titanium alloys, can solve the problems of poor biological properties of coatings, shorten treatment time, etc., achieve good nano-effects, shorten treatment time, and promote osteogenesis differentiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

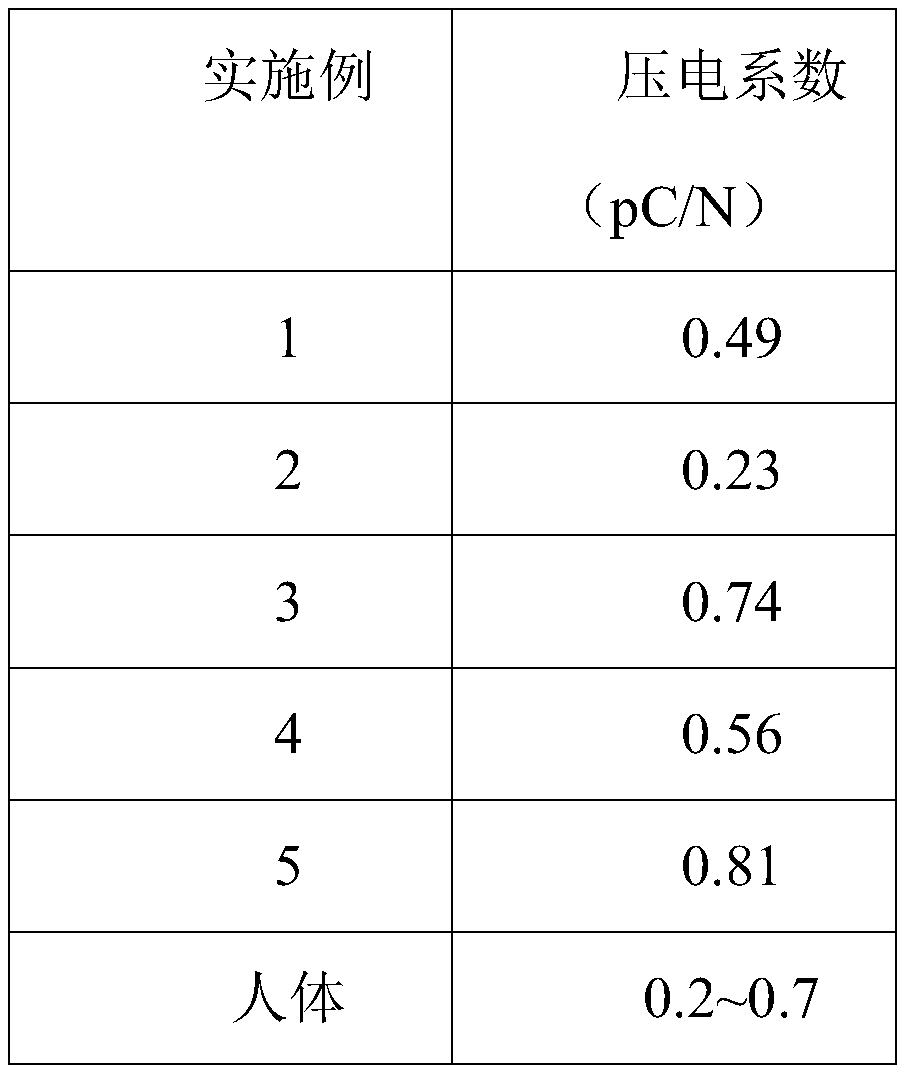

Examples

Embodiment 1

[0029] Step 1: Titanium Alloy Treatment

[0030] Polish the surface of the titanium sheet to a mirror surface; then put it into a chemical polishing solution for polishing;

[0031] Step 2: Preparation of titanium dioxide nanotube coating on titanium alloy surface

[0032] Ammonium fluoride and water are added to ethylene glycol in a certain proportion and stirred evenly to obtain a clear and transparent electrolyte; the platinum sheet is used as the cathode, and the titanium alloy treated in step 1 is used as the anode, and the distance between the anode and the cathode is fixed and controlled. The anodizing voltage and anodizing time make the titanium alloy undergo an anodic oxidation reaction; after the reaction is completed, the titanium alloy is taken out, cleaned, and then annealed to form a titanium dioxide nanotube coating on the surface of the titanium alloy;

[0033] Among them, the mass ratio of ammonium fluoride, water, and ethylene glycol is 3:50:1950; the distan...

Embodiment 2

[0041] Step 1: Same as Step 1 of Example 1, the only difference is: replace the titanium sheet with a titanium nail, and directly perform chemical polishing;

[0042] Step 2: roughly the same as Step 2 of Example 1, the only difference is that the mass ratio of ammonium fluoride, water, and ethylene glycol is 10:100:1900 in sequence; the distance between the anode and the cathode is 30mm; the anodic oxidation voltage 40~80V; oxidation time is 5h; cleaning method is ultrasonic cleaning; annealing temperature is 150℃, and annealing time is 15h.

[0043] Step 3: It is roughly the same as Step 3 of Example 1, except that the molar concentration of the calcium hydroxide aqueous solution is 0.5 mol / L; the hydrothermal temperature is 150° C., and the hydrothermal time is 5 hours; the cleaning method is ultrasonic cleaning.

[0044] Step 4: roughly the same as Step 4 of Example 1, the only difference is that in the electrochemical deposition reaction, the current is 1mA, and the time ...

Embodiment 3

[0046] Step 1: It is roughly the same as Step 1 of Example 1, the only difference is: replace the titanium sheet with a titanium nail, and directly perform chemical polishing;

[0047]Step 2: roughly the same as Step 2 of Example 1, the only difference is that the mass ratio of ammonium fluoride, water, and ethylene glycol is 5:150:1850 in sequence; the distance between the anode and the cathode is 20mm; the anodic oxidation voltage 40 ~ 80V; oxidation time is 2h; cleaning method is ultrasonic cleaning; annealing temperature is 400 ℃, annealing time is 5h.

[0048] Step 3: It is roughly the same as Step 3 of Example 1, except that the molar concentration of the strontium hydroxide aqueous solution is 0.1 mol / L; the hydrothermal temperature is 220° C., and the hydrothermal time is 1 h; the cleaning method is ultrasonic cleaning.

[0049] Step 4: roughly the same as Step 4 of Example 1, the only difference is that in the electrochemical deposition reaction, the current is 10mA, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com