Method for preparing polyvinylidene fluoride piezo film with microstructure

A polyvinylidene fluoride piezoelectric and polyvinylidene fluoride technology is applied in the field of preparation of polyvinylidene fluoride piezoelectric films, which can solve the problems of polymer film defects and inability to manufacture micro-devices, and achieve the effect of easy alignment and orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a polyvinylidene fluoride piezoelectric film with a microstructure:

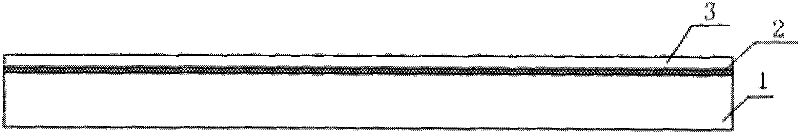

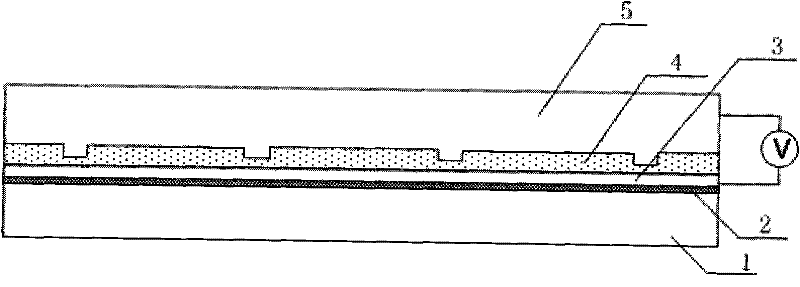

[0029] 1) Preparation of the metal electrode layer 3: prepare a layer of 300nm SiO on the silicon substrate 1 2 Make an insulating isolation layer 2, and then sputter a 100nm metal electrode layer 3 on the insulating isolation layer 2, such as figure 1 shown;

[0030] 2) Configuration of polymer solution: polyvinylidene fluoride PVDF powder or polyvinylidene fluoride PVDF and its copolymer powder are used as a solute, dissolved in a mixed solution of dimethylformamide DMF and acetone at 15°C to prepare A polymer solution with a concentration of 70g / L, the volume ratio of dimethylformamide DMF to acetone in the mixed solution is 95:5, stirred with a magnetic stirrer for 60 minutes, placed in vacuum for 1 / 2 hour, and sealed for 72 hours;

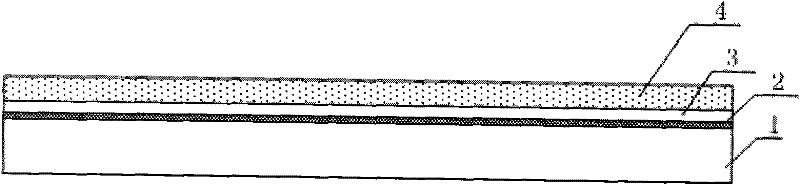

[0031] 3) Polymer solution spin-coating: Spin-coat the solution prepared in step 2) on the metal electrode layer 3 with a commercially avail...

Embodiment 2

[0036] A preparation method of a polyvinylidene fluoride piezoelectric film with a microstructure:

[0037] 1) Preparation of the metal electrode layer 3: prepare a layer of 400nm SiO on the silicon substrate 1 2 Make an insulating isolation layer 2, and then sputter a 200nm metal electrode layer 3 on the insulating isolation layer 2, such as figure 1shown;

[0038] 2) Configuration of polymer solution: Polyvinylidene fluoride PVDF powder is used as a solute, dissolved in a mixed solution of dimethylformamide DMF and acetone at 20°C, and the volume ratio of dimethylformamide DMF to acetone is 30:70, prepared into a polymer solution with a concentration of 40g / L, stirred with a magnetic stirrer for 60 minutes, placed in vacuum for 2 hours, and sealed for 12 hours;

[0039] 3) Polymer solution spin coating: use a commercially available spin coater to spin coat the prepared solution on the metal electrode layer 3 at a speed of 1000 rpm to obtain a polymer layer 4, such as fig...

Embodiment 3

[0044] A preparation method of a polyvinylidene fluoride piezoelectric film with a microstructure:

[0045] 1) Preparation of the metal electrode layer: prepare a layer of 500nm SiO on the silicon substrate 1 2 Make an insulating isolation layer 2, and then sputter a 400nm metal electrode layer 3 on the insulating isolation layer 2, such as figure 1 shown;

[0046] 2) Configuration of polymer solution: polyvinylidene fluoride PVDF powder or polyvinylidene fluoride PVDF and its copolymer powder are used as solute, dissolved in a mixed solution of dimethylformamide DMF and acetone at 17°C to prepare Concentration is the polymer solution of 45g / L, the volume ratio of dimethylformamide DMF and acetone is 50:50, after stirring the polymer solution with a magnetic stirrer for 30 minutes, put the polymer solution in a vacuum for 1 hour, seal and place 45 hours;

[0047] 3) Polymer solution spin-coating: Spin-coat the solution prepared in step 2) on the metal electrode layer 3 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com