Preparation method of environment-friendly repair material for electronic screen of handheld device

An environmentally friendly and repairing material technology, applied in the direction of non-polymer adhesive additives, adhesive additives, inorganic adhesives, etc., can solve the problems of limited performance, complex preparation of repairing materials, preparation and use pollution, etc. To achieve long-lasting effects, non-toxic and harmless to the human body, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

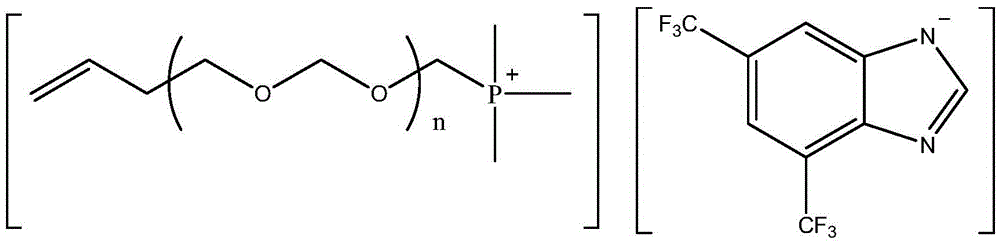

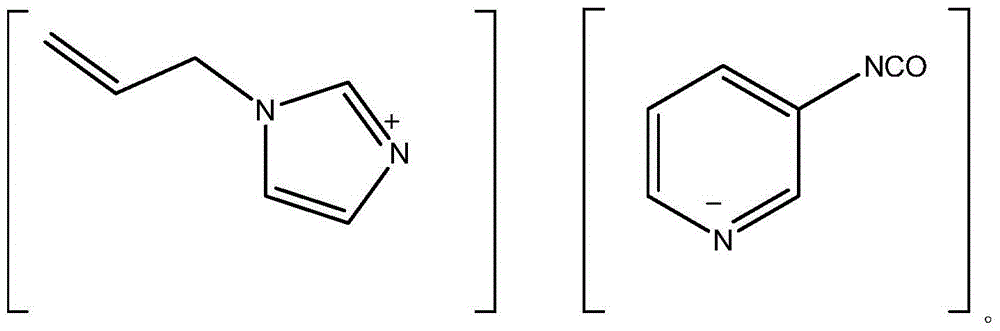

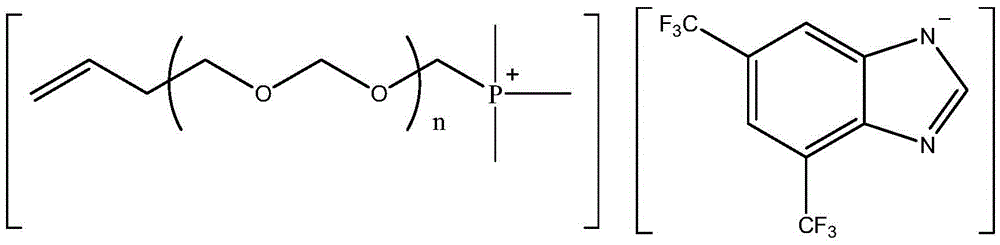

Method used

Image

Examples

Embodiment 1

[0029] Add 200 grams of deionized water, 800 grams of ethanol, 100 grams of non-oxidized graphene, and 10 grams of nano-calcium carbonate (average particle diameter of 80 nanometers) in a 2000 ml four-necked flask, and stir and disperse evenly at room temperature. Then add 6 grams of ionic liquid A and 3 grams of ionic liquid B, stir evenly and set aside at room temperature. The pH value of the self-healing composite material is detected by precision pH test paper, the mechanical properties of the material are tested by the national standard GB‐T1040 tensile performance test, and the piezoelectric response performance of the material under the one-dimensional plane wave impact load is tested by using the Hopkinson pressure bar. The test and repair effect are comprehensively evaluated by grades of poor, unqualified, good, and excellent. The test results are as follows:

[0030]

Embodiment 2

[0032] Add 150 grams of deionized water, 850 grams of ethanol, 105 grams of non-oxidized graphene, and 5 grams of nano-calcium carbonate (average particle size of 20 nanometers) in a 2000 ml four-necked flask, and stir and disperse evenly at room temperature. Then add 8 grams of ionic liquid A and 2 grams of ionic liquid B, stir evenly and set aside at room temperature. The pH value of the self-healing composite material is detected by precision pH test paper, the mechanical properties of the material are tested by the national standard GB‐T1040 tensile performance test, and the piezoelectric response performance of the material under the one-dimensional plane wave impact load is tested by using the Hopkinson pressure bar. The test and repair effect are comprehensively evaluated by grades of poor, unqualified, good, and excellent. The test results are as follows:

[0033]

Embodiment 3

[0035] Add 100 grams of deionized water, 850 grams of ethanol, 180 grams of non-oxidized graphene, and 15 grams of nano-calcium carbonate (average particle diameter of 100 nanometers) in a 2000 ml four-necked flask, and stir and disperse evenly at room temperature. Then add 6 grams of ionic liquid A and 1 gram of ionic liquid B, stir evenly and set aside at room temperature. The pH value of the self-healing composite material is detected by precision pH test paper, the mechanical properties of the material are tested by the national standard GB‐T1040 tensile performance test, and the piezoelectric response performance of the material under the one-dimensional plane wave impact load is tested by using the Hopkinson pressure bar. The test and repair effect adopts four grades: poor, unqualified, good and excellent to comprehensively evaluate. The test results are as follows:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com