Preparation method for micro-nano piezoelectric fiber

A piezoelectric fiber, micro-nano technology, applied in fiber processing, textiles and papermaking, artificial filament physical therapy, etc., can solve the problems of complex process, large size of chemical fiber, and inability to prepare fiber mechanism, so as to avoid complicated process, The effect of low material cost and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

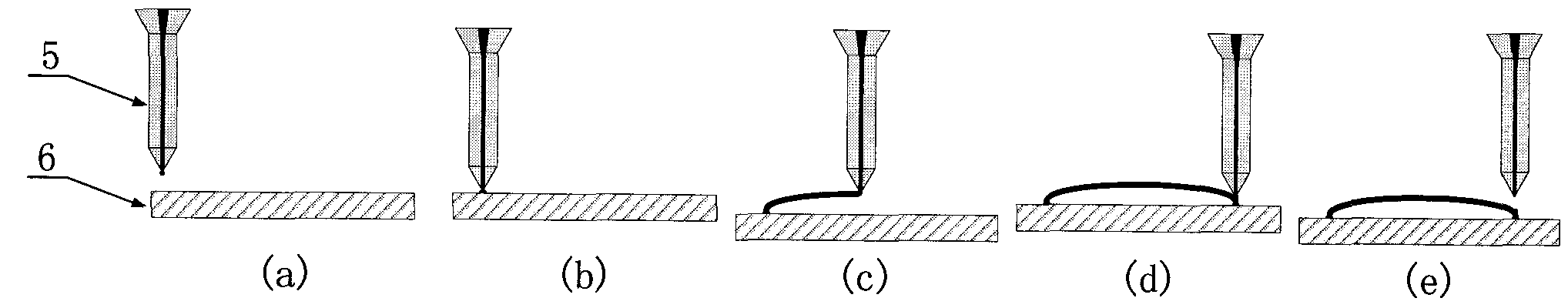

[0018] The invention utilizes a micro-injection pump to extrude a solution in which piezoelectric materials are dissolved from a glass capillary micro-needle, and prepares micro-nano-scale piezoelectric fibers at a specific position of a substrate through movement of a three-dimensional operating platform and solvent evaporation during stretching.

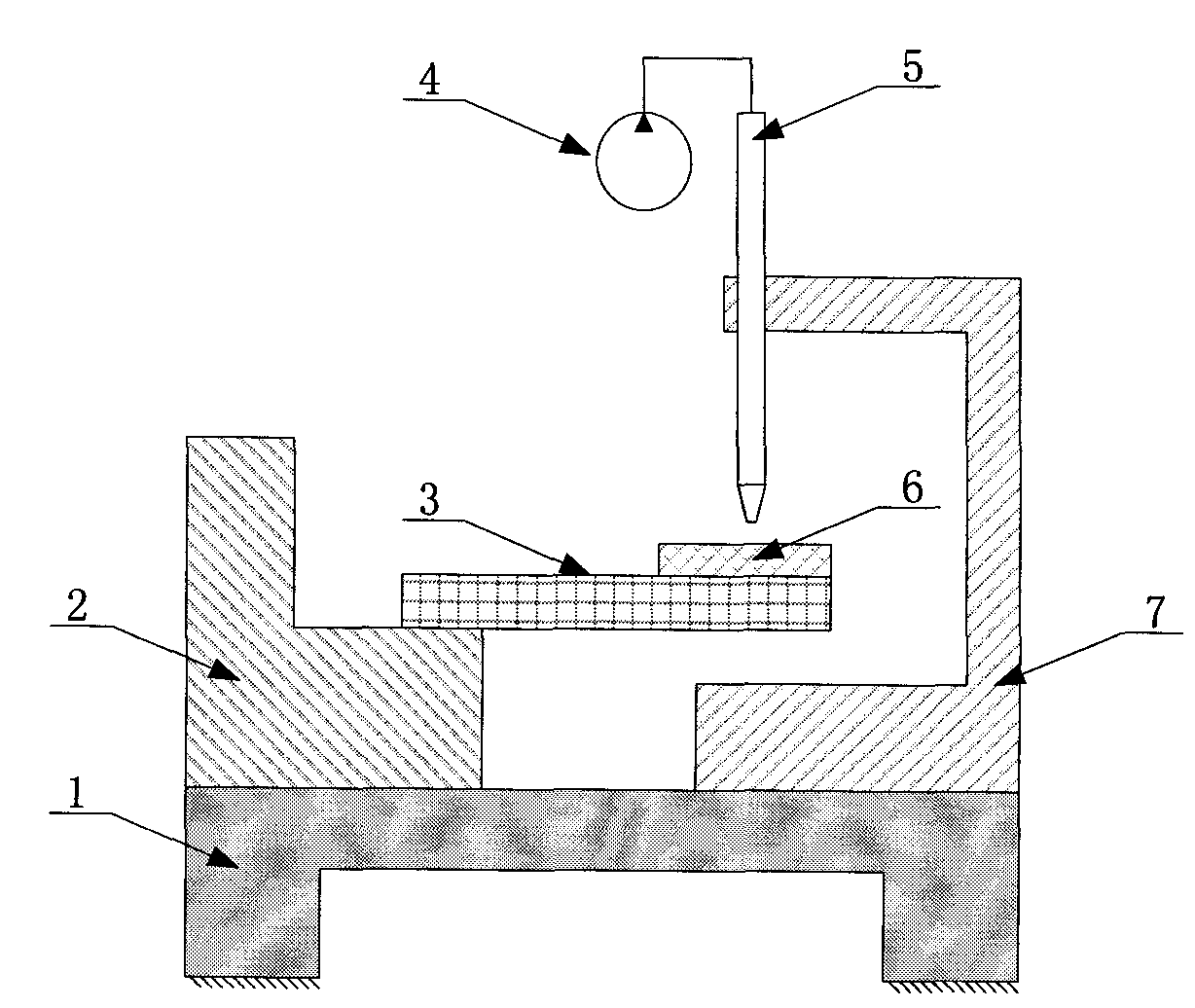

[0019] Such as figure 1 As shown, the preparation platform of micro-nano-scale piezoelectric fibers is composed of an experimental bench 1, an automatic three-dimensional operation platform 2, a heating plate 3, a substrate 6, a glass capillary microneedle 5 and a micro-injection pump 4. The heating plate 3 is fixed on the automatic three-dimensional operation platform 2, the base 6 is fixed on the heating plate 3, and the material used for the base is polyimide. The glass capillary micro-needle 5 is clamped and installed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com