Knee endoprosthesis for replacing at least parts of the knee joint

A technology of prosthesis and knee, applied in the field of knee prosthesis, can solve problems such as looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

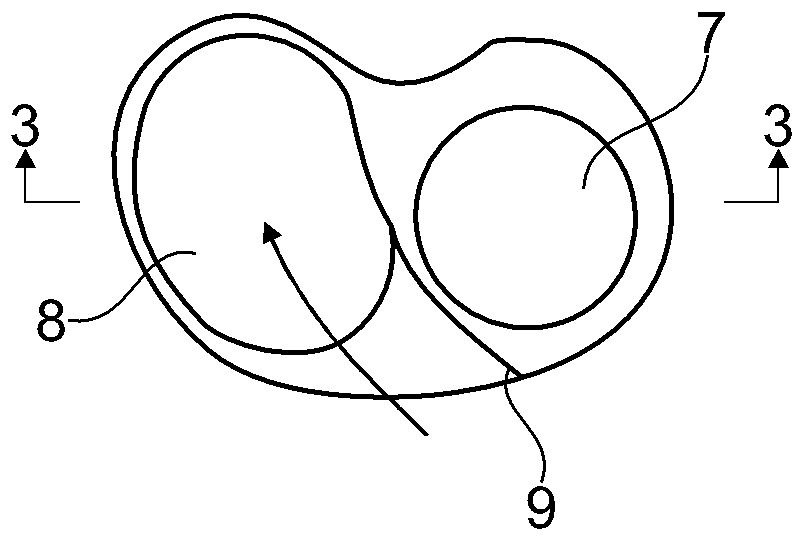

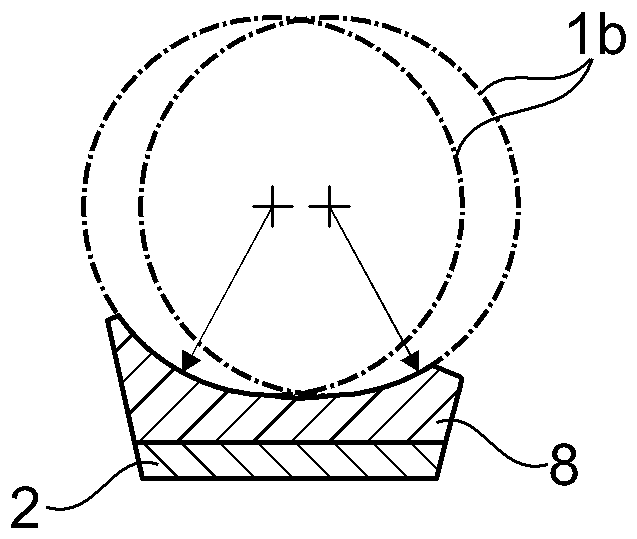

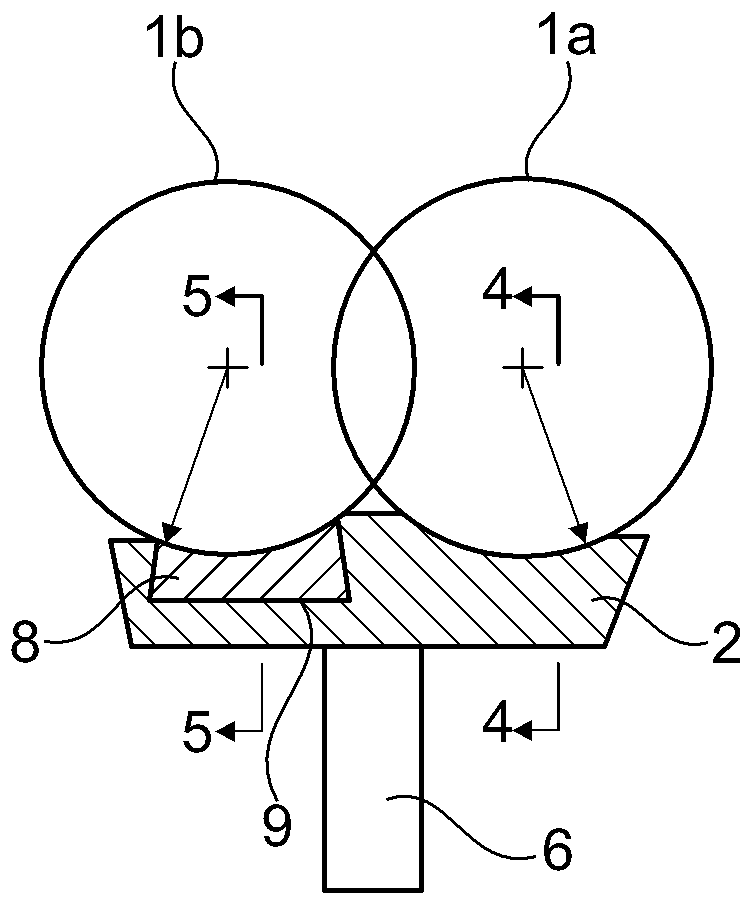

[0016] figure 1 shows a knee endo-articular prosthesis according to the invention with a femoral component having a femoral component 1 consisting of two condylar surfaces 1a, 1b for anchoring in the distal femur, and the knee endoprosthesis with tibial component 2 for anchoring at the proximal tibia. The tibial component is formed by the tibial plateau, on the underside of which faces the tibia a pin 6 is arranged for anchoring. On the upper side, that is to say on the side of the tibial plateau facing the femoral component 1 , an inner bearing shell 7 is arranged according to the invention as an integral part of the ceramic tibial plateau. The inner carrier shell 7 is spherical in shape. Both the femoral component 1 and the tibial component 2 are made of solidly sintered ceramic, that is to say ceramic components. This provides a ceramic / ceramic sliding pair which is virtually wear-free even under prolonged use. Arranged laterally next to the medial bearing shell 7 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com