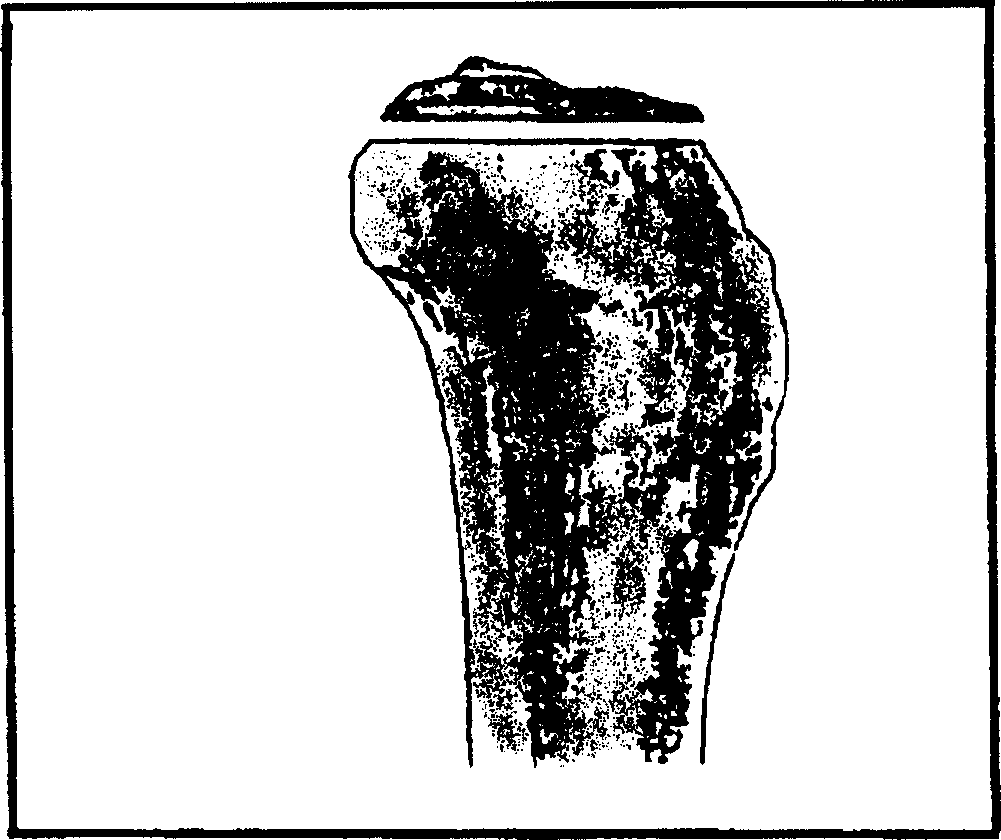

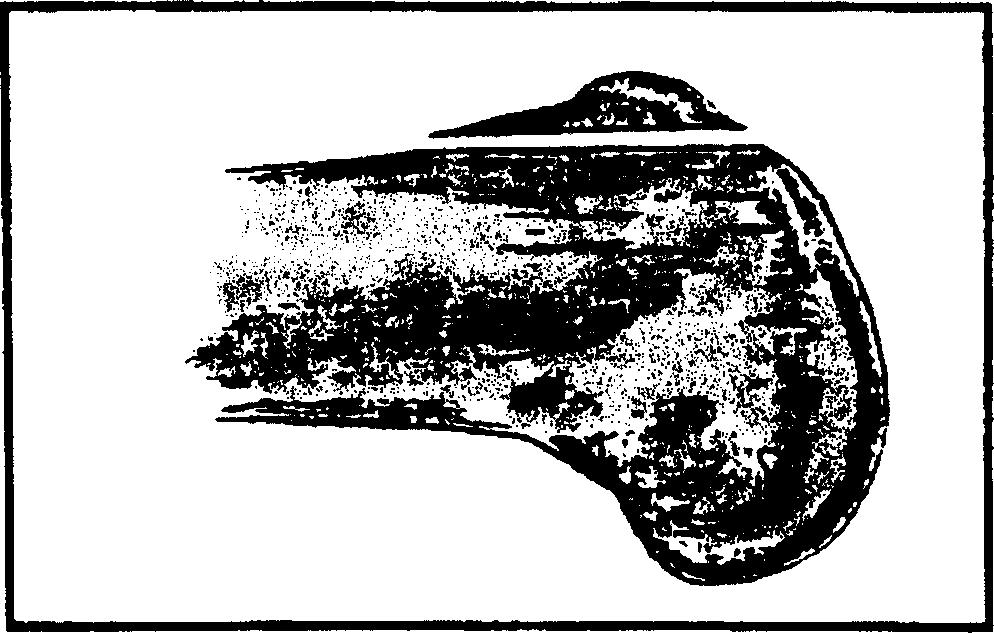

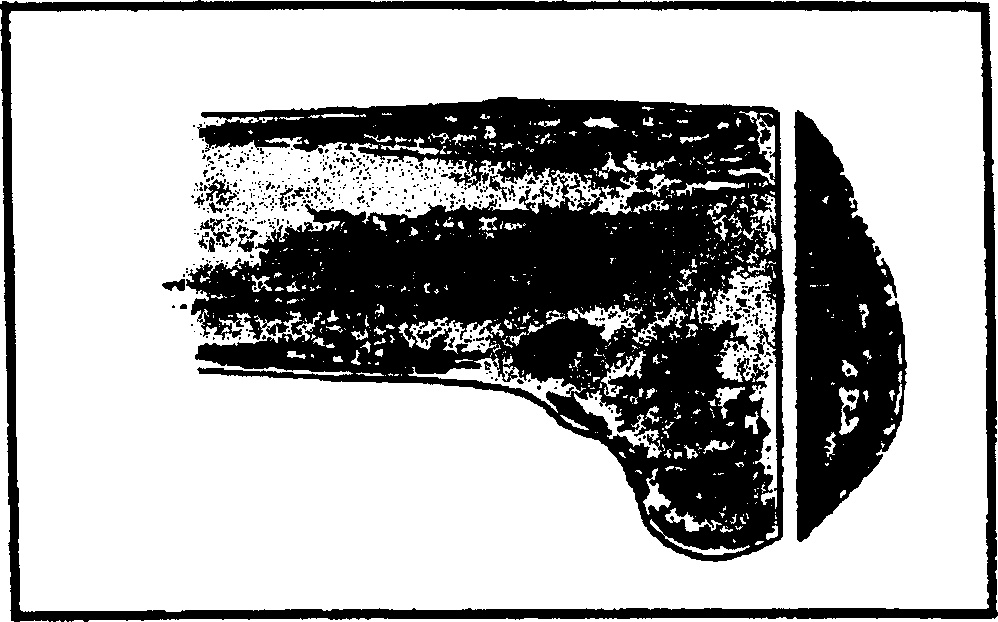

Femur formation and cutting center

A technology for femoral condyle and bone cutting, which is applied in the field of cutters for forming and processing femoral condyle at one time, can solve the problems of long operation time and unexpected situations, and achieves the effect of shortening operation time, reducing work intensity and reducing blood loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Refer to the attached Figure 7 ~9 describes in detail a preferred embodiment of a femoral condyle shaping cutter 10 provided by the present invention. exist Figure 7 In the illustrated embodiment, the femoral condyle shaping cutter 10 provided by the present invention includes a main drive shaft 15 arranged in the transmission gearbox 4 . The main drive gear 14 installed on the main drive shaft 15 . The first driven gear 12 meshing with the main drive gear 14 is installed on the first driven shaft 13 . The first output shaft 13 is mounted in the transmission gearbox 4 . The main drive gear 14 meshes with an intermediate gear 16 , and the intermediate gear 16 is mounted on an intermediate shaft 17 . The intermediate shaft 17 is mounted in the transmission gearbox 4 . The intermediate gear 16 meshes with a second driven gear 18 mounted on a second driven shaft 19 supported in the transmission gearbox 4 .

[0024] from Figure 7 It can be seen from the figure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com