Special-shaped tobacco carton automatic stacking and packing method

A packaging method and a technology for stick cigarettes, which are applied in the directions of packaging, transportation and packaging, and stacking of objects, can solve the problems of unsuitable judgment of responsibility, occupation of work space, and many operators, and achieve shortening of the running path, stability and space saving, The effect of improving palletizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

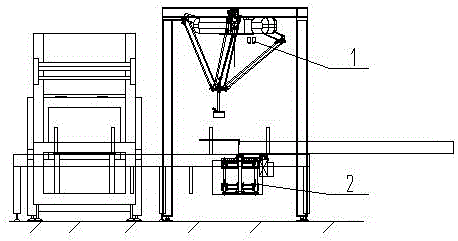

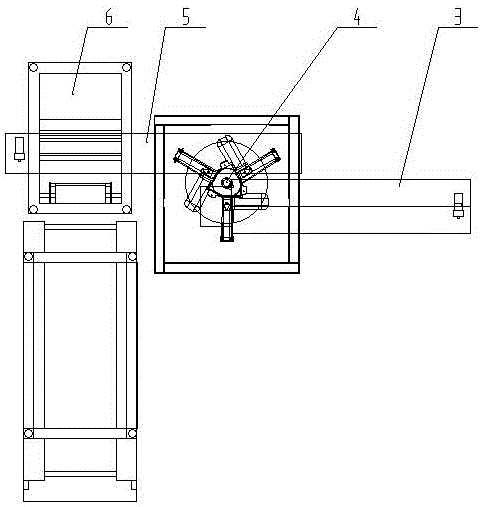

[0017] Such as figure 1 , 2 As shown, a method for automatic palletizing and packaging of special-shaped cigarettes comprises the following steps:

[0018] 1) The operator reads the order data of the upstream sorting system through the control software of the palletizing manipulator 4; and sets the corresponding relationship between the palletizing manipulator 4 and the real-time order of the sorting system; that is, the management system automatically obtains the order data of the current sorting order Customer name, cigarette product specification, quantity of cigarettes, line, date and other information;

[0019] 2) Transport the cigarettes sorted by the sorting system to the end of the cigarette conveying device 3; at the baffle;

[0020] 3) Fiber optic sensors are installed at both ends of the baffle plate of the cigarette conveying device 3; after the fiber optic sensor detects that the cigarettes are in place, the camera and light source in the measurement and positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com