Top drive drilling device coupling clamping type sleeve lowering device and application method thereof

A casing device and coupling clamp technology, applied in drilling equipment and methods, drilling equipment, drill pipes, etc., can solve problems such as restricting the popularization and application of casing running devices, affecting the safety and efficiency of casing running devices, etc. , to achieve the effect of safe and reliable use, ensuring sealing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

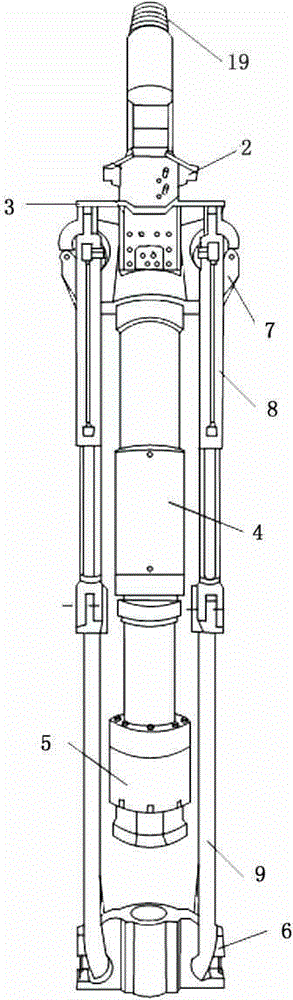

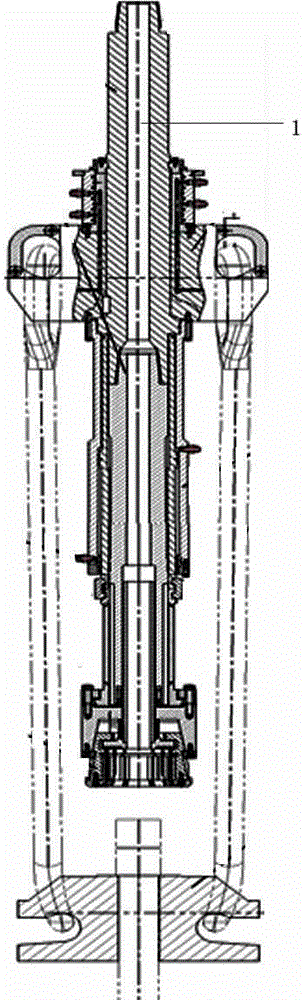

[0026] Such as figure 1 and figure 2 As shown, a top drive drilling equipment collar clamping type casing running device, the center pipe 1 is provided with a rotary sealing connection plate 2, a suspension support seat 3, a main hydraulic cylinder 4 and a tong head body 5 from top to bottom. , a casing elevator 6 is provided below the clamp head main body 5, a suspension body 7 is provided on the lower end surface of the suspension support seat 3, and a suspension ring 9 is fixedly connected to the lower end surface of the suspension body 7, and the lower end of the suspension ring 9 is connected with the casing elevator 6, and the suspension ring 9 The surface is provided with the tilting hydraulic cylinder 8 of the suspension ring. Through the action of the tilting hydraulic cylinder 8 of the lifting ring, the tilting of the lifting ring 9 opens the casing elevator 6, so that the casing elevator 6 can smoothly grab the oil casing.

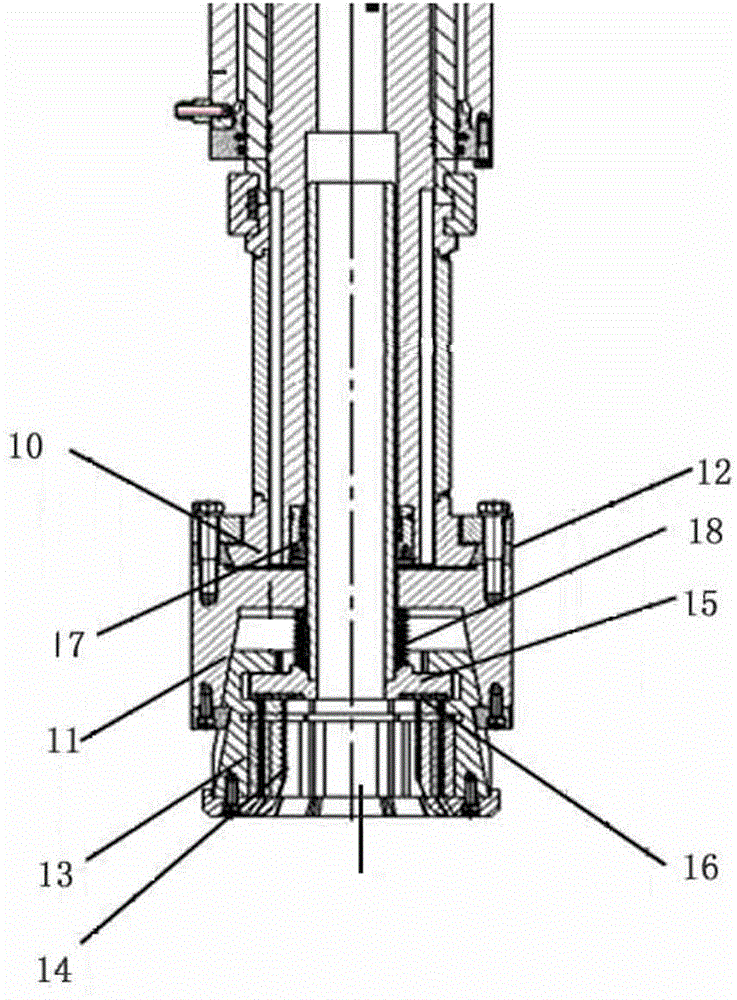

[0027] Such as image 3 As shown, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com