Compact small angle precision rotating mechanism

A rotating mechanism, small angle technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of high cost of accurate rotation and positioning, and achieve the effect of simple structure, high control accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

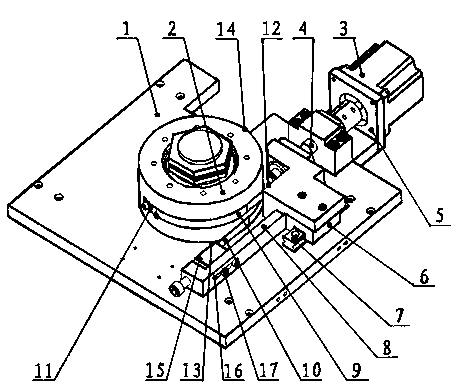

[0009] The present invention is described in detail below in conjunction with accompanying drawing:

[0010] A compact small-angle precision rotating mechanism, including a PLC and a base plate 1, a cylindrical turntable 2 is movable on the base plate 1, and a screw motor seat 5 and a slide are fixedly installed on the base plate 1 on one side of the cylindrical turntable 2. Block guide rail 7, lead screw nut 6 is movably arranged on slide block guide rail 7, lead screw drive motor 3 is arranged on lead screw motor base 5, lead screw 4 on the lead screw drive motor 3 is connected with lead screw nut 6 Together, a stretching block 8 is provided on the lead screw nut 6, an adjusting block 15 is arranged at the front end of the stretching block 8, and a lower spring leaf fixing screw 14 and an upper spring leaf fixing screw are respectively arranged on the side of the cylindrical turntable 2. 11. One end of the lower spring piece 10 is connected with the cylindrical turntable 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com