Karst tunnel operation period base plate separation layer rotary spraying grouting technology and grouting device

A grouting device and layer-separation technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of non-diffusion of diseased sections, recurrence of floor water gushing, poor reinforcement effects, etc., achieve excellent reinforcement effects, improve soil strength, less stressful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

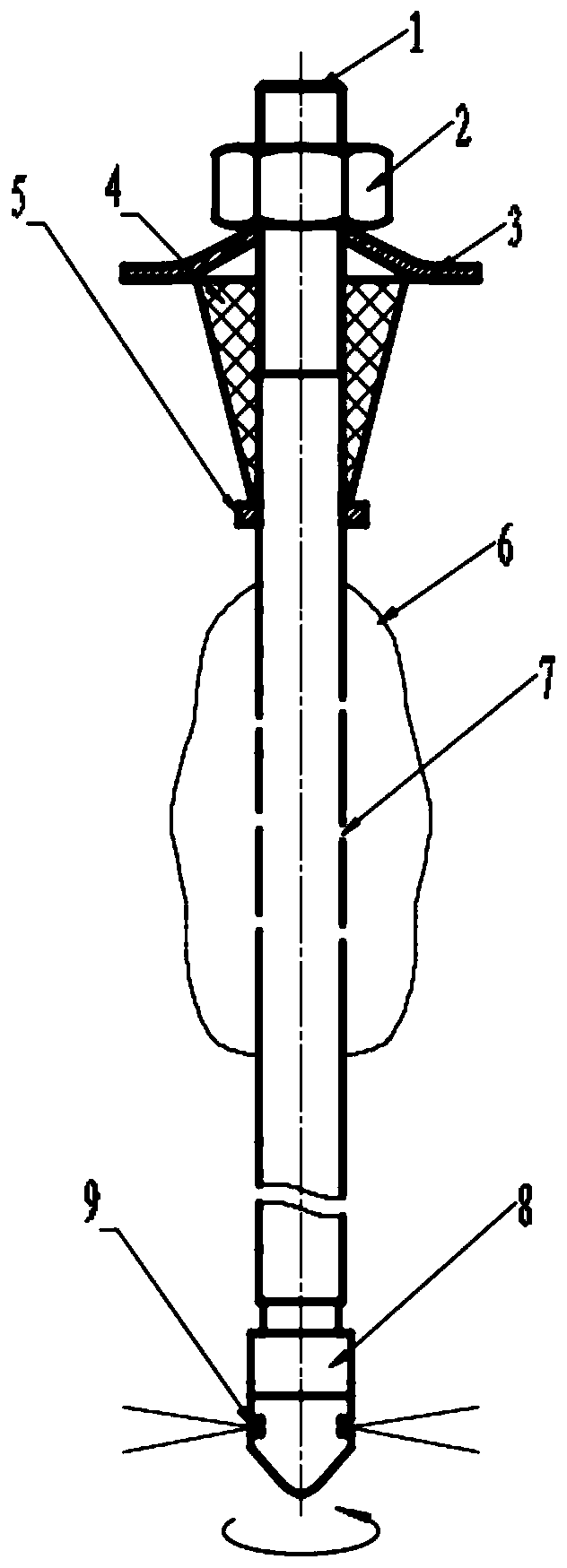

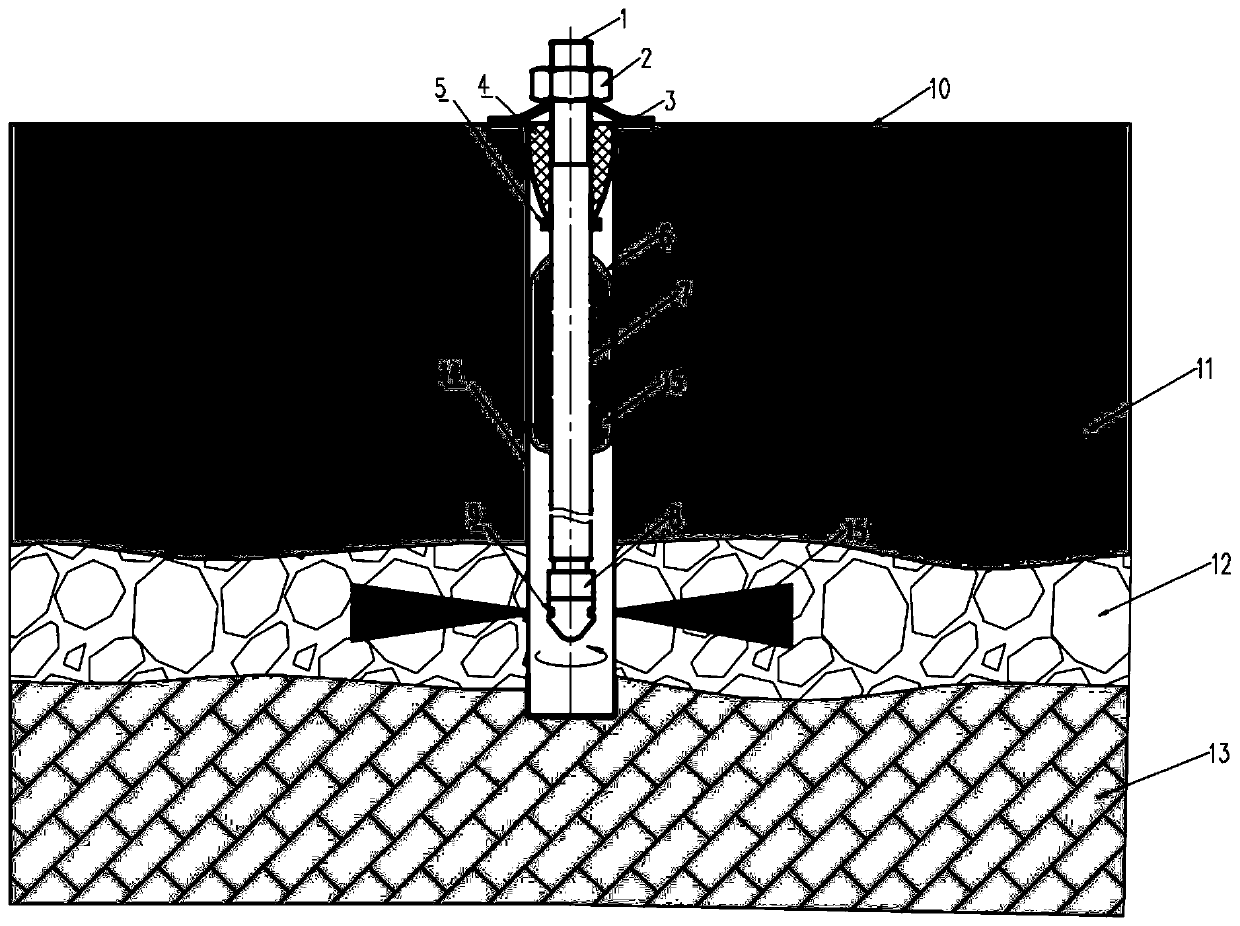

[0044] A rotary jet grouting device for the floor separation layer during the operation period of the karst tunnel, refer to figure 1 , including: a grouting pipe 1, a nut 2, a tray 3, a grout stopper 4, a block 5, a film bag 6, an overflow hole 7, a self-rotating nozzle 8 and a nozzle 9.

[0045] One end of the grouting pipe 1 is open, and the outer surface of the open end is provided with an external thread that cooperates with the nut 2, and the tray 3 is provided with a through hole that can pass through the open end of the grouting pipe. The stopper 5 is fixedly arranged on the outer surface of the grouting pipe 1 , the grout stopper 4 is sleeved on the grouting pipe 1 , and the grout stopper 4 is located between the stopper 5 and the tray 3 .

[0046] The other end of the grouting pipe 1 communicates with the self-rotating nozzle 8, the self-rotating nozzle 8 is provided with a nozzle 9, the self-rotating nozzle 8 rotates under the action of the high-pressure slurry, and...

Embodiment 2

[0049] A karst tunnel floor separation rotary jet grouting process during the operation period, the process includes the following steps:

[0050] (1) Comprehensive exploration of floor abscission layers of karst operating tunnels

[0051] Comprehensively analyze the hydrogeological data during the exploration period and construction excavation period of the karst operation tunnel, and comprehensively analyze the generation mechanism of the floor separation layer 12 from the structural environment, stratum lithology and groundwater; use the combination of geological radar and high-density direct current method The geophysical prospecting method explores the tunnel floor area, roughly determines the spatial distribution range of the floor separation layer 12 and the corresponding general depth, and provides a decision-making basis for the delineation of the grouting treatment target area and the design of the treatment plan.

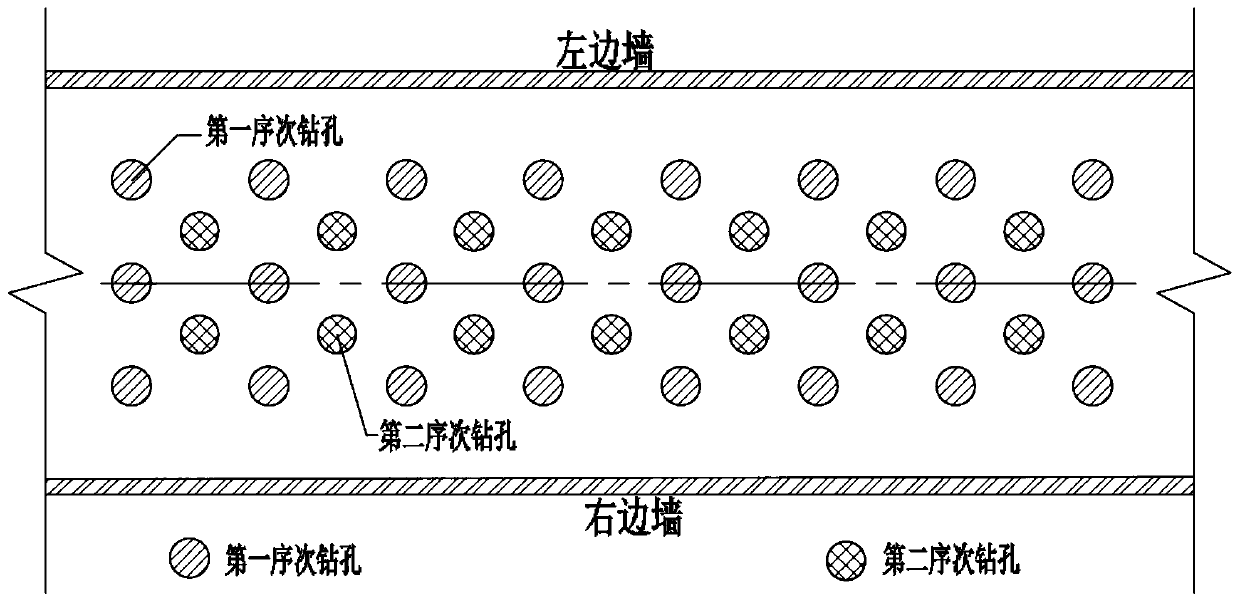

[0052] (2) Governance plan design

[0053] 1) Dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com