Asymmetric-structure-based organic semiconductor thin film oriented-preparation method and characterization method

An organic semiconductor and asymmetric structure technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, test crystals, etc., can solve the problems of device operating speed reduction, slow film formation speed, and inability to meet the needs of orientation growth, etc., to achieve small The effect of parasitic capacitance and fast switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

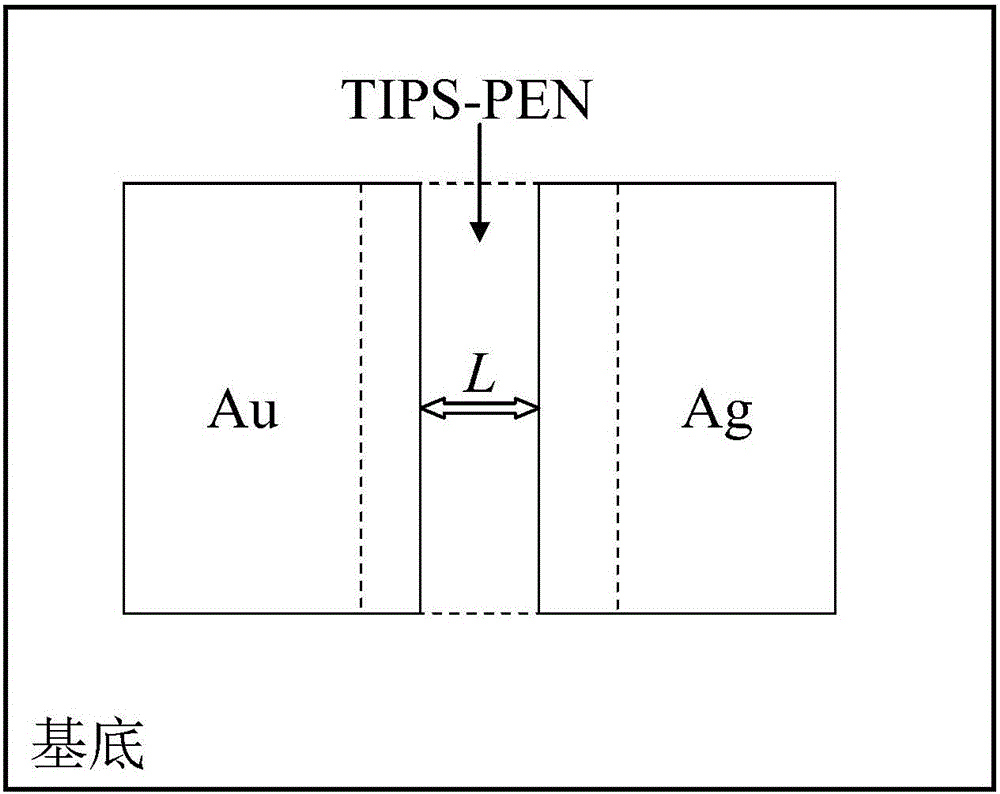

[0037] Embodiment 1 Utilizes the method for preparing organic semiconductor film by asymmetric planar structure orientation

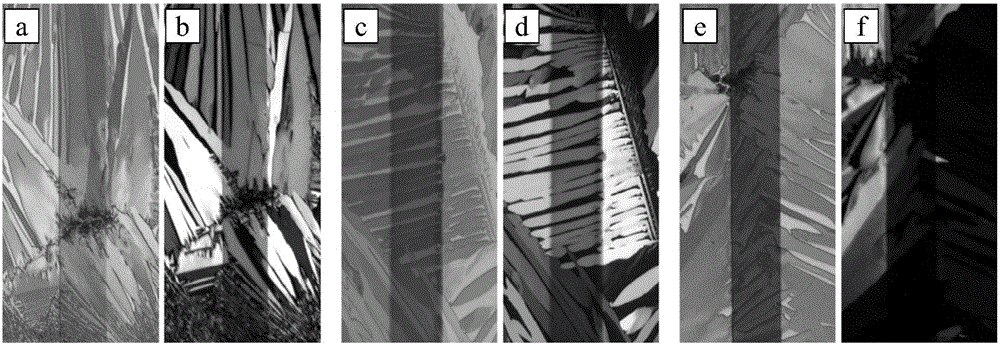

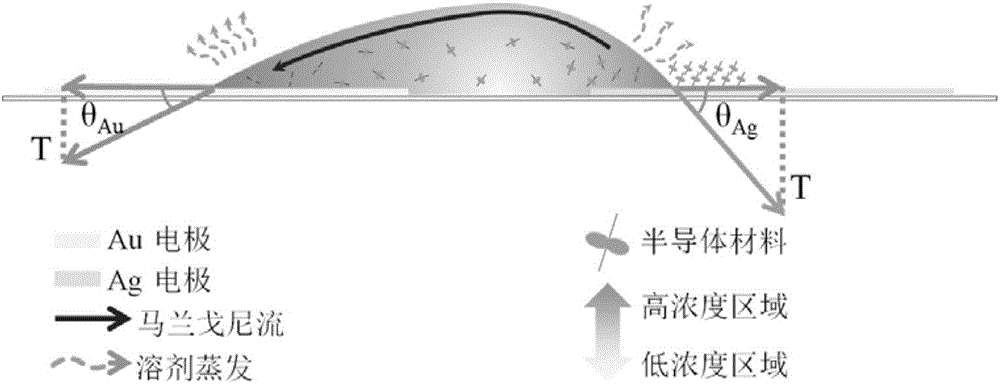

[0038] In this embodiment, the method for preparing an organic semiconductor thin film using an asymmetric planar structure orientation is: take material A and material B, there is a difference in surface energy between the two, and the contact angle between material A and the organic semiconductor precursor solution to be printed is greater than that of material A. The contact angle between B and the organic semiconductor precursor solution to be printed; the patterned films of material A and material B are respectively formed on the substrate, which are respectively film A and film B, and there is a channel in the middle of film A and film B, defining the channel The channel length L is the shortest distance between film A and film B, and the direction corresponding to the channel length is the channel length direction; the precursor solution of the or...

Embodiment 2

[0046] Embodiment 2 Utilizes the method for preparing film by asymmetric stereostructure orientation

[0047] In this embodiment, the method for preparing a thin film using asymmetric stereostructure orientation is as follows: Figure 5 As shown, film C and film D are arranged at intervals on the substrate, and film C and film D are connected by an arc-shaped transition of film E, the thickness of film C is greater than the thickness of film E, and the thickness of film D is greater than or equal to the thickness of film E , the minimum radius of curvature at the joint between film C and film E is smaller than the minimum radius of curvature at the joint between film D and film E; define the spacing direction from film C to film D as the width direction of film E or the channel length direction, and print by inkjet The precursor solution of the organic semiconductor thin film material is printed on the horizontal substrate along the horizontal direction perpendicular to the wi...

Embodiment 3

[0050] The characterization method of the orientation strength of the oriented growth film of embodiment 3

[0051] The characterization method of the orientation strength of the oriented growth film in this embodiment is to characterize the in-plane orientation strength of the oriented growth film through the out-of-plane X-ray diffraction spectrum. The orientation strength includes two quantitative evaluation indicators: the consistency of the orientation growth direction and the degree of orientation growth. Continuity, the specific characterization steps are:

[0052] (1) first determine whether the organic semiconductor film to be characterized is oriented growth through a polarizing microscope, and if so, proceed to step (2);

[0053](2) Define the angle between the X-ray incident surface of out-of-plane X-ray diffraction and the expected growth direction of the organic semiconductor thin film to be characterized as the test azimuth angle α, and take Δα as the change ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com