Novel environment-friendly type water-based glass baking paint and preparation method thereof

A glass baking paint, water-based technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy peeling, unevenness and low surface free energy of the paint layer, and achieve improved glass adhesion, good paint film performance, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

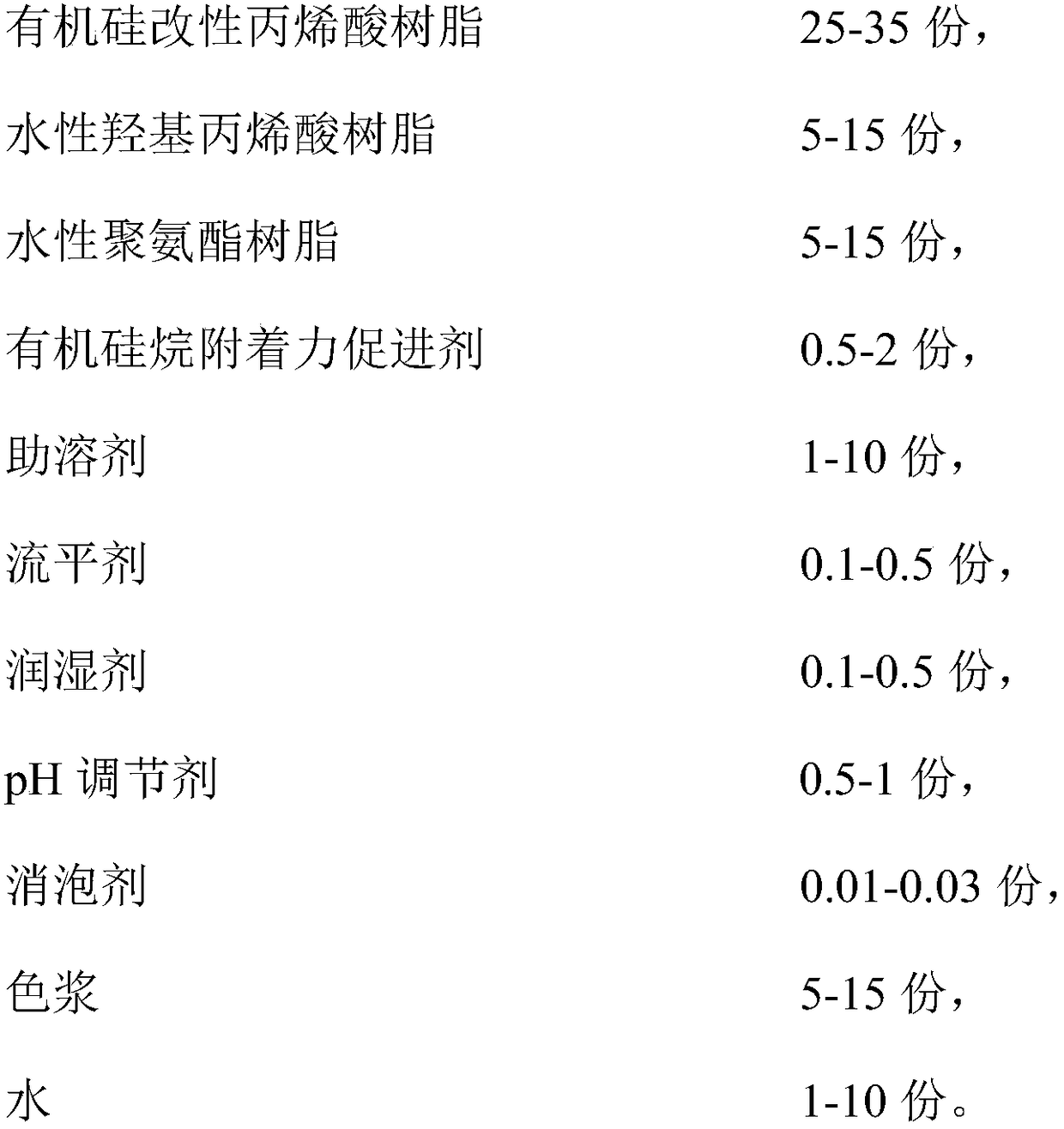

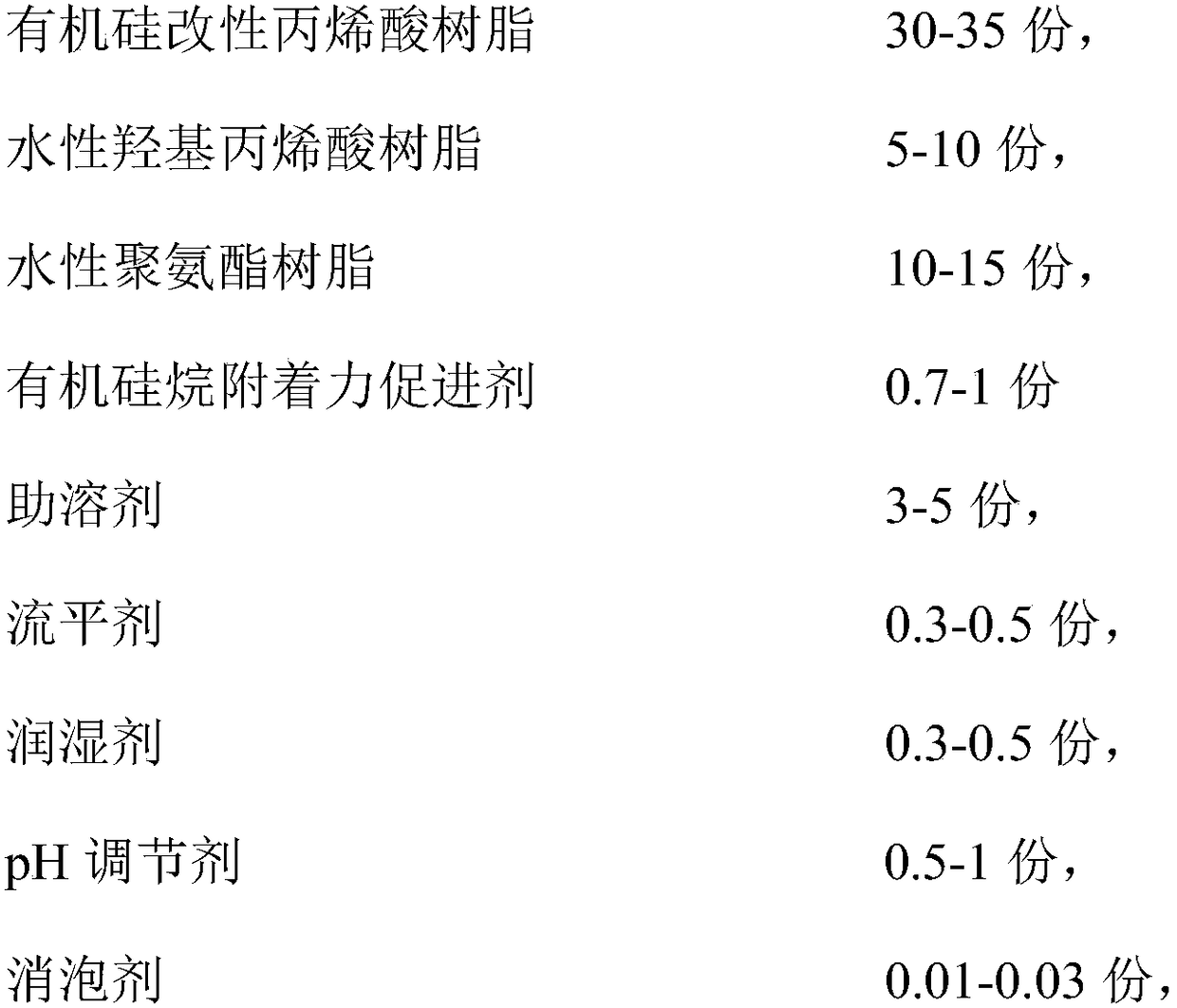

Method used

Image

Examples

Embodiment 1

[0029] a) Preparation of color paste: Weigh the raw materials according to pigment: dispersant: water mixing = 4:1:8, first stir the water and dispersant evenly, then add the pigment, set the speed at 2500r / min, grind and disperse for 30min. Then scrape the fineness, control the fineness ≤ 10 μm, and prepare the color paste for later use;

[0030] b) Add 30 parts of epoxy hydrocarbyl silane modified acrylic resin, 10 parts of water-based hydroxyl acrylic resin, 10 parts of hexamethoxymethylmelamine formaldehyde resin, 0.3 part of wetting agent and 0.01 part of aminopolyether silicone defoamer in sequence In the mixing equipment, pre-stir for 15 minutes at a speed of 500r / min;

[0031] c) At a speed of 500r / min, add 0.8 parts of γ-(2,3 glycidoxy)propyltrimethoxysilane, 4 parts of co-solvent, 0.4 parts of leveling agent, 0.7 parts of pH regulator, color Mix 8 parts of slurry, 4 parts of water and 0.01 part of amino polyether silicone defoamer, continue to stir for 20 minutes un...

Embodiment 2

[0033] a) Preparation of color paste: Weigh the raw materials according to pigment: dispersant: water mixing = 3:1:6, first stir the water and dispersant evenly, then add the pigment, set the speed at 2000 / min, grind and disperse for 30 minutes. Then scrape the fineness, control the fineness ≤ 10 μm, and prepare the color paste for later use;

[0034] b) Defoaming 25 parts of methacryloxyalkylsilane modified acrylic resin, 15 parts of water-based hydroxyacrylic resin, 13 parts of methylated melamine formaldehyde resin, 0.1 part of wetting agent and polyether grafted polysiloxane Add 0.02 parts of the agent to the stirring equipment in turn, and pre-stir for 15 minutes at a speed of 500r / min;

[0035] c) At a speed of 500r / min, add 2 parts of γ-(2,3 glycidoxy)propyltrimethoxysilane, 8 parts of co-solvent, 0.5 parts of leveling agent, 0.5 parts of pH regulator, color 13 parts of slurry, 10 parts of water and 0.01 part of polyether-grafted polysiloxane defoamer, continue to stir...

Embodiment 3

[0037] a) Preparation of color paste: Weigh the raw materials according to pigment: dispersant: water mixing = 5:1:10, first stir the water and dispersant evenly, then add the pigment, set the speed at 3000 / min, grind and disperse for 30 minutes. Then scrape the fineness, control the fineness ≤ 10 μm, and prepare the color paste for later use;

[0038] b) 35 parts of methacryloxyalkylsilane modified acrylic resin, 5 parts of water-based hydroxyacrylic resin, 5 parts of hexamethoxymethylmelamine formaldehyde resin, 0.5 part of wetting agent and 0.01 part of polyether silicone defoamer Parts are added to the stirring equipment in turn, and pre-stirred for 15 minutes at a speed of 500r / min;

[0039] c) At a speed of 500r / min, add 0.5 parts of γ-(2,3 glycidoxy)propyltrimethoxysilane, 8 parts of cosolvent, 0.2 parts of leveling agent, 0.9 parts of pH regulator, color 7 parts of slurry, 3 parts of water and 0.02 parts of polyether silicone defoamer, continue to stir for 15 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com