Rectangular steel tube variable-cross-section steel core anti-buckling limiting energy dissipation supporting member assembled with bolt shaped like Chinese character 'tian'

A technology of square steel pipes and energy-dissipating supports, which is applied to building components, earthquake resistance, etc., can solve the problems of less research on the limit effect of buckling supports, and achieve the effects of superior performance, expanded application range, and convenient purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

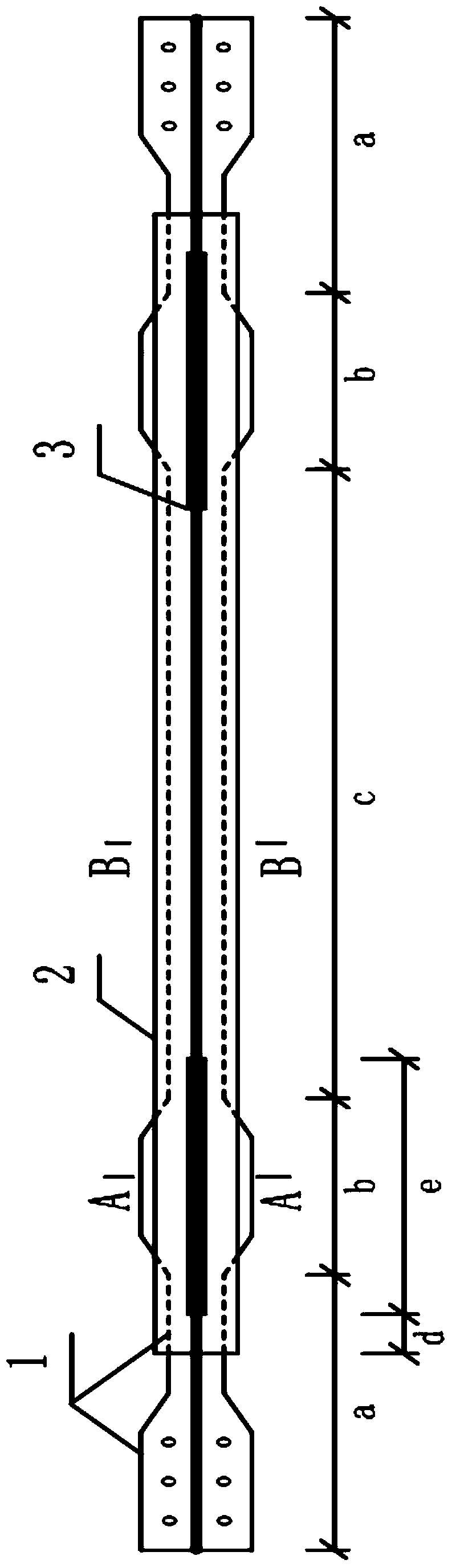

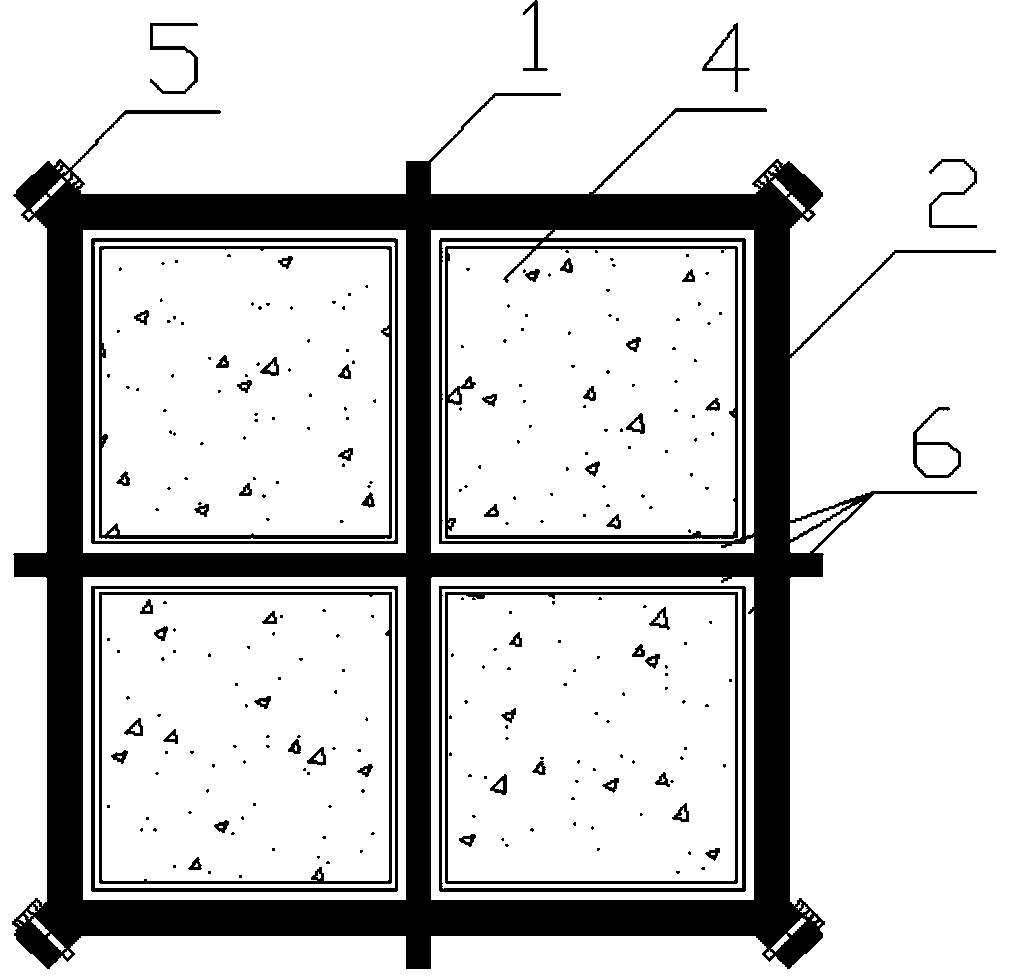

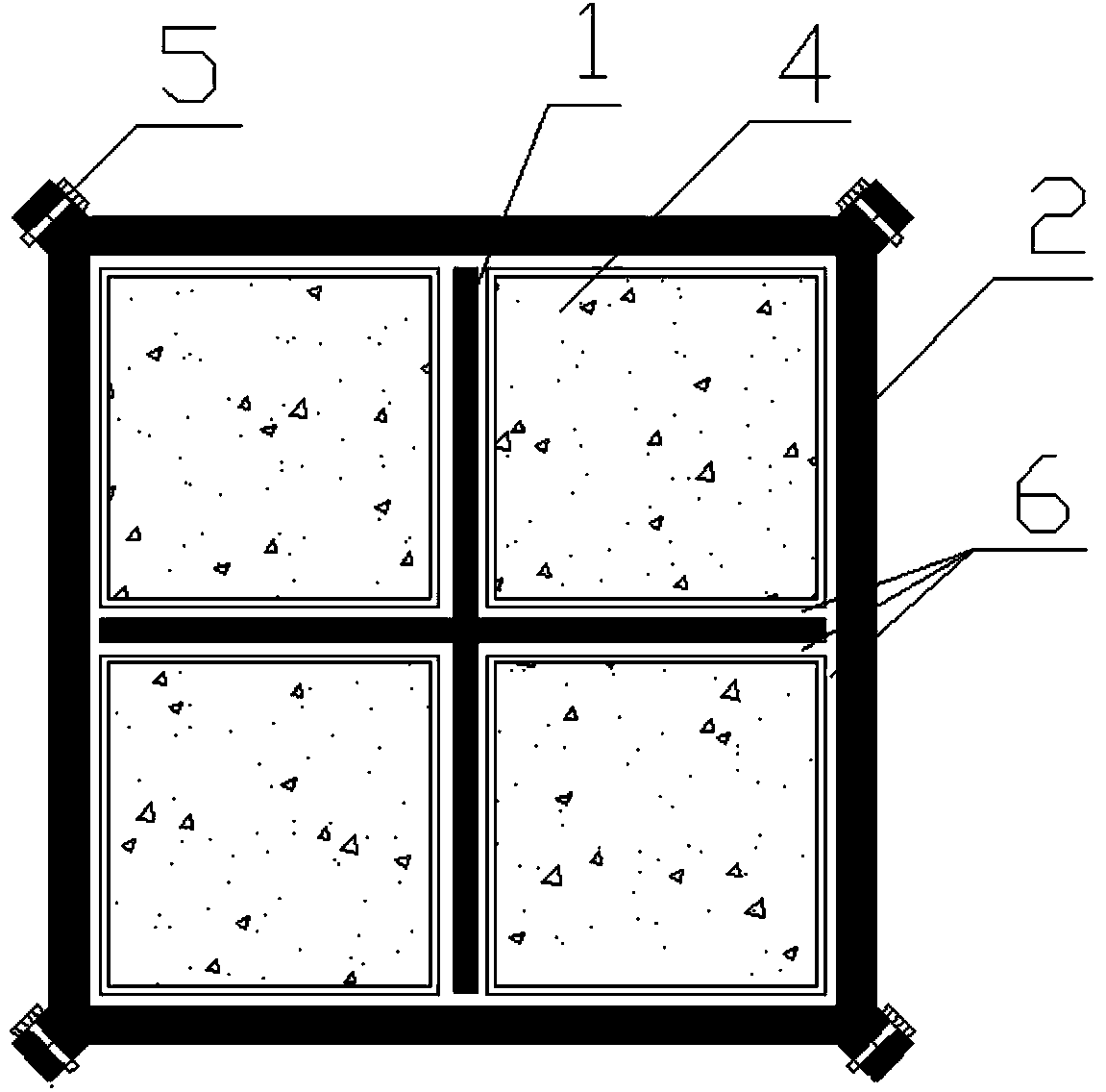

[0023] Such as figure 1 As shown, a buckling-resistant energy-dissipating support member assembled with rectangular steel pipe variable-section steel core with cross-shaped bolts. It includes a cross-shaped steel core (1) and an outer constraint body (2), and the size of the outer constraint body is 300×300mm. The cross-shaped steel core (1) includes a connection section a, a section with a locally enlarged section b, and a yield working section c. The section of the cross-shaped steel core (1) is partially enlarged at the outer steel pipe limiting groove (3) at a slope angle of 60° until the cross section passes through the outer steel pipe limiting groove (3) by 30 mm. Four thin-walled steel-filled steel tube concrete (4) are filled between the cross-shaped energy-dissipating steel core (1) and the outer restraint steel tube (2). The outer constraining steel pipe (2) is assembled from 4 steel plates, the ends of the steel plates are bent 135° outward by 50 mm, and two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com